A kind of antifouling coating capable of releasing antifouling agent and preparation method thereof

An antifouling and antifouling technology, applied in antifouling/underwater coatings, coatings, paints containing biocides, etc. It is easy to long-term secretion and other problems to achieve the effect of low cost, high wear resistance and improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The preparation process of component two is as follows:

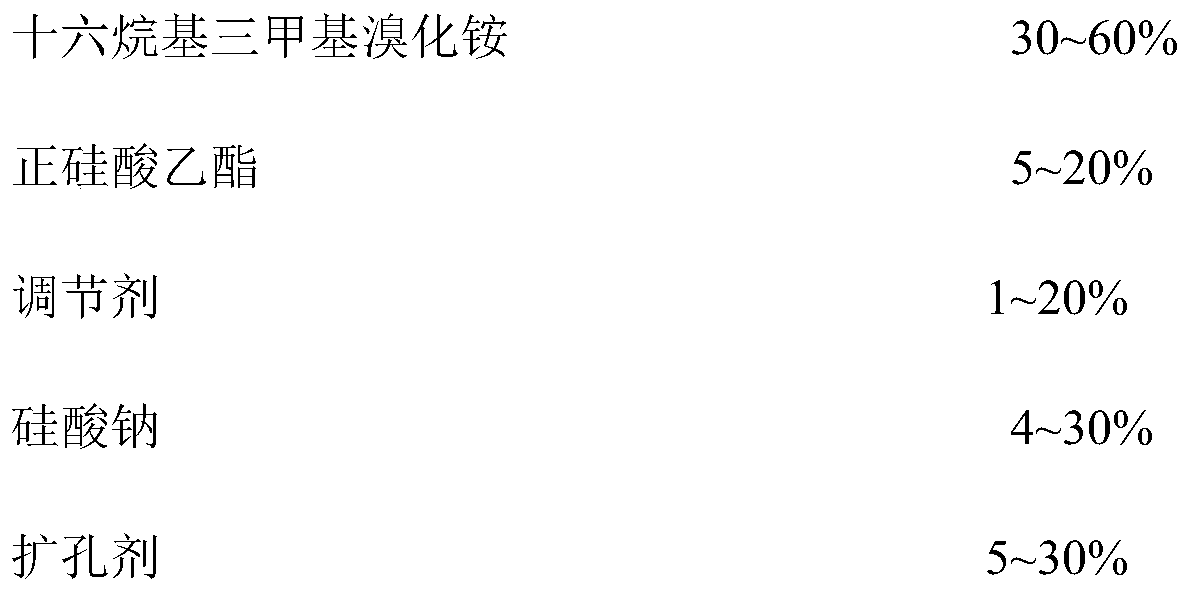

[0051] First prepare mesoporous silica particles, the specific process is as follows:

[0052] 1) Add 30-60% cetyltrimethylammonium bromide into the container by mass percentage, then add distilled water, heat to 40-60°C to dissolve cetyltrimethylammonium bromide Finally, add 1 to 20% regulator while stirring;

[0053] 2) After stirring for 10 minutes, add 5-20% ethyl orthosilicate, 4-30% sodium silicate and 5-30% pore-enlarging agent and stir, and react at a constant temperature of 40-60°C for 24-36 hours;

[0054] 3) Stand at room temperature for 6-8 days, filter, and dry at 110°C for 1-4 hours to obtain a white powder that is mesoporous silica particles;

[0055] Then use the second component prepared by mesoporous silica particles, the specific process is as follows:

[0056] Add mesoporous silica particles into water, disperse evenly by ultrasonic, then add antifouling ingredients and keep stirring for 2-...

Embodiment 1

[0066] Hydrophobically modified antifouling agent-releasing antifouling coatings were prepared according to the following steps:

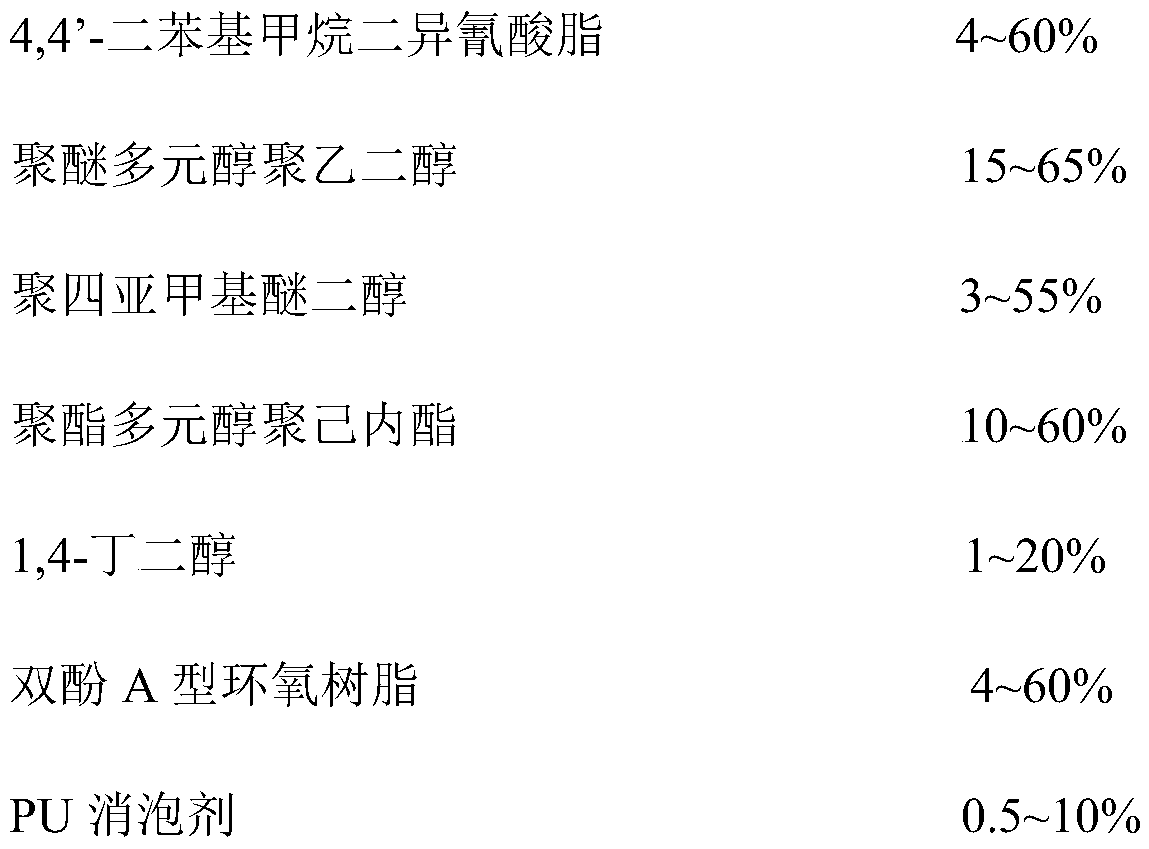

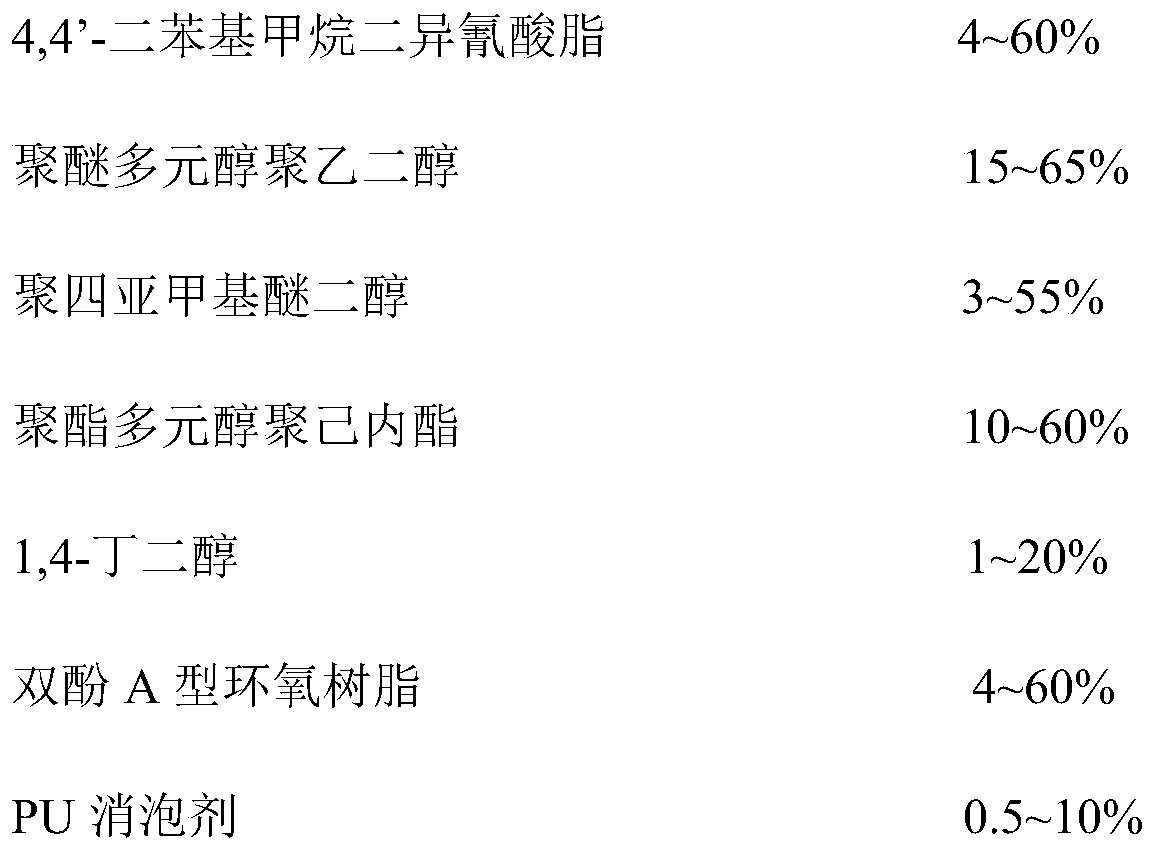

[0067] The preparation process of component one is as follows:

[0068] 1) In terms of mass percentage, 3% polytetramethylene ether glycol (PTMG) and 65% polyether polyol polyethylene glycol (PEG) are added to a three-necked flask (500ml) equipped with a thermometer and a stirrer. ), heated to 100°C, and vacuum dehydrated at 0.667kPa for 4h;

[0069] 2) Cool down to 65°C, add 4% of 4,4'-diphenylmethane diisocyanate (MDI) and 4% of bisphenol A epoxy resin;

[0070] 3) After reacting for 30 minutes, add 20% 1,4-butanediol for chain extension;

[0071] 4) After reacting for 1 hour, add 4% PU defoaming agent and stir rapidly. After the air bubbles are eliminated, stop the reaction to obtain component one.

[0072] The preparation process of component two is as follows:

[0073] First prepare mesoporous silica particles loaded with antifouling compo...

Embodiment 2

[0081] The preparation process of component one is as follows:

[0082] 1) In terms of mass percentage, 4% polytetramethylene ether glycol (PTMG) and 15% polyether polyol polyethylene glycol (PEG) are added to a three-necked flask (500ml) equipped with a thermometer and a stirrer. ), heated to 105°C, and vacuum dehydrated at 0.667kPa for 3h;

[0083] 2) Cool down to 65°C, add 10% 4,4'-diphenylmethane diisocyanate (MDI) and 60% bisphenol A epoxy resin;

[0084] 3) After reacting for 40 minutes, add 1% 1,4-butanediol for chain extension;

[0085] 4) After reacting for 2 hours, add 10% PU defoaming agent and stir rapidly. After the bubbles are eliminated, stop the reaction to obtain component one.

[0086] The preparation process of component two is as follows:

[0087] First prepare mesoporous silica particles, the process is as follows:

[0088] (1) In terms of mass percentage, add 40% cetyltrimethylammonium bromide into the container, then add distilled water, heat at 50°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com