A kind of micro-alloyed magnesium alloy sheet with high formability and preparation method thereof

A technology of microalloying and magnesium alloying, applied in the field of high formability microalloying magnesium alloy sheet and its preparation, can solve the problems of poor plasticity at room temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

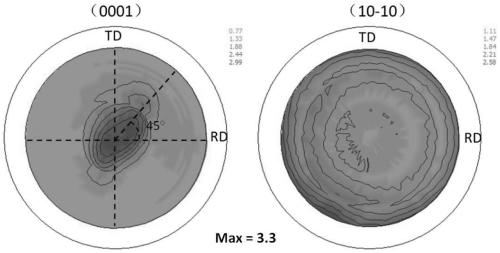

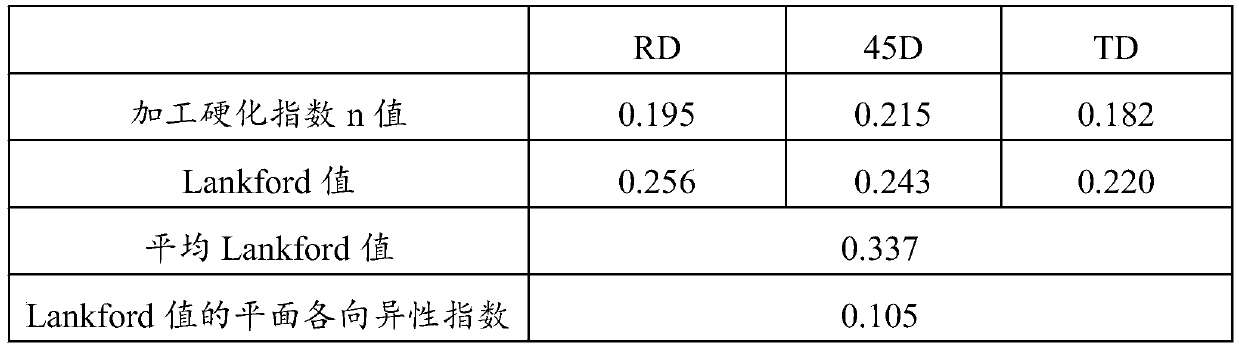

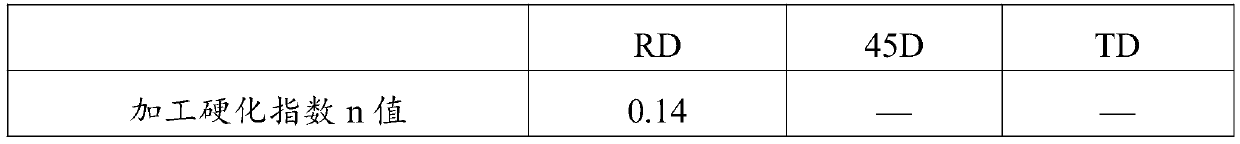

Image

Examples

Embodiment 1

[0063] A micro-alloyed magnesium alloy thin plate with high formability, its composition and the mass percentage of each component are: 1.0% zinc, 0.6% ytterbium, 0.4% zirconium, and the balance is magnesium and unavoidable impurity elements.

[0064] A method for preparing a micro-alloyed magnesium alloy thin plate with high formability, the steps are as follows:

[0065] Step 1. Melting process

[0066] Weigh the corresponding raw materials according to the alloy composition and the content of each component, melt the prepared industrial pure magnesium, industrial pure zinc, magnesium-ytterbium master alloy, and magnesium-zirconium master alloy in an ordinary resistance furnace, and add industrial The addition temperature of pure magnesium, industrial pure zinc and magnesium-ytterbium master alloy is 730°C, and the addition temperature of magnesium-zirconium master alloy is 760°C. After the alloy elements are completely melted, high-purity argon is continuously introduced in...

Embodiment 2

[0080] A micro-alloyed magnesium alloy thin plate with high formability, its composition and the mass percentage of each component are: 0.5% zinc, 0.3% ytterbium, 0.2% zirconium, and the balance is magnesium and unavoidable impurity elements.

[0081] A method for preparing a micro-alloyed magnesium alloy thin plate with high formability, the steps are as follows:

[0082] Step 1. Melting process

[0083] Weigh the corresponding raw materials according to the alloy composition and the content of each component, melt the prepared industrial pure magnesium, industrial pure zinc, magnesium-ytterbium master alloy, and magnesium-zirconium master alloy in an ordinary resistance furnace, and add industrial The addition temperature of pure magnesium, industrial pure zinc and magnesium-ytterbium master alloy is 730°C, and the addition temperature of magnesium-zirconium master alloy is 760°C. After the alloy elements are completely melted, high-purity argon is continuously introduced in...

Embodiment 3

[0097] A micro-alloyed magnesium alloy thin plate with high formability, its composition and the mass percentage of each component are: 0.5% zinc, 0.5% ytterbium, 0.3% zirconium, and the balance is magnesium and unavoidable impurity elements.

[0098] A method for preparing a micro-alloyed magnesium alloy thin plate with high formability, the steps are as follows:

[0099] Step 1. Melting process

[0100] Weigh the corresponding raw materials according to the alloy composition and the content of each component, melt the prepared industrial pure magnesium, industrial pure zinc, magnesium-ytterbium master alloy, and magnesium-zirconium master alloy in an ordinary resistance furnace, and add industrial The addition temperature of pure magnesium, industrial pure zinc and magnesium-ytterbium master alloy is 730°C, and the addition temperature of magnesium-zirconium master alloy is 760°C. After the alloy elements are completely melted, high-purity argon is continuously introduced in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com