Sandstone wall surface and construction method thereof

A construction method and sandstone technology, applied in covering/lining, construction, building structure, etc., can solve the problems of heavy stone weight, unreliable adhesion, difficult to form sandstone effect, etc., to improve the firmness and service life. , Stabilize and maintain the sandstone effect, and facilitate the effect of color fixing and color development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

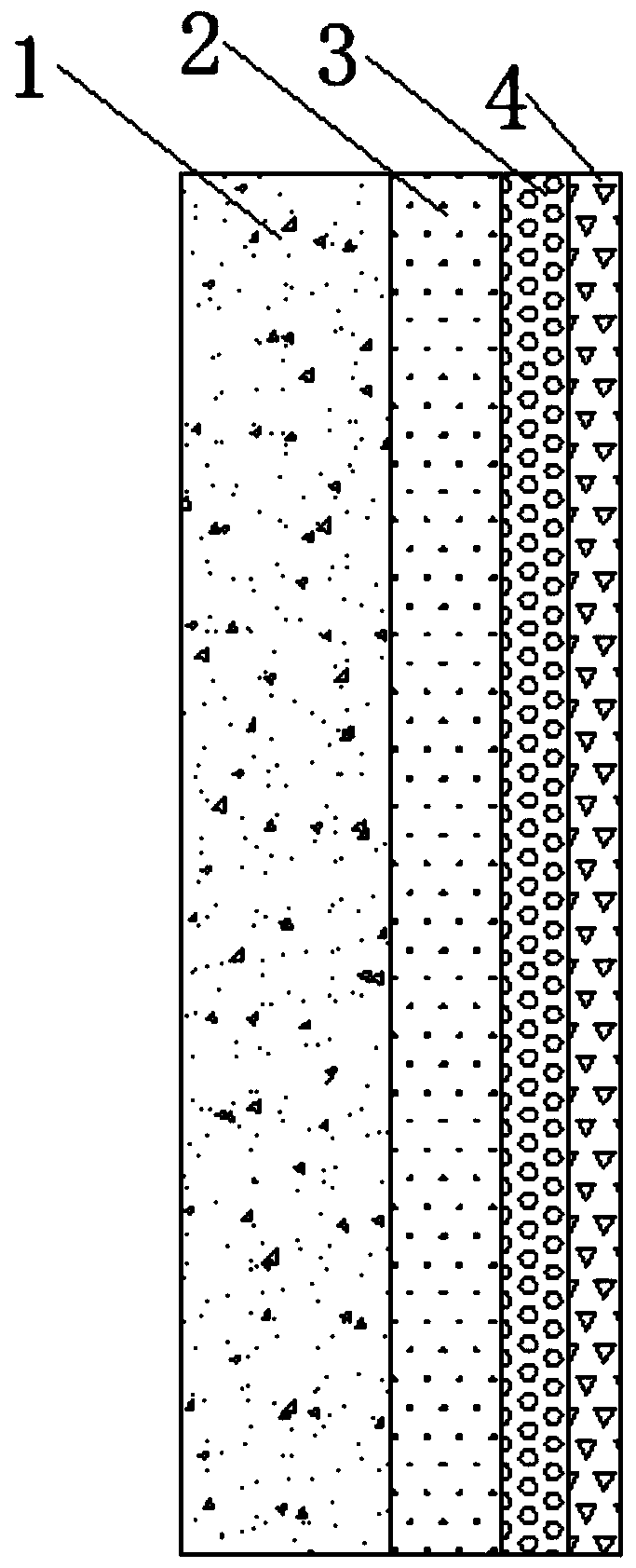

[0078] Such as image 3 Shown is a schematic diagram of the cross-sectional structure of the sandstone wall surface directly in contact with the sandstone texture paint on the wall surface. From the wall surface to the outer layer: 1 is the wall surface, 2 is the middle layer of sandstone texture, 3 is the sandstone texture finish layer, 4 as the overcoat; the above attached image 3 The concrete construction steps are as follows:

[0079] (1) Check and clean the wall surface to be constructed, remove dust, polish uneven places, and obtain a flat wall surface; wet the wall surface with water;

[0080] (2) Then carry out the coating of sandstone texture paint on the wall (here can adopt batch scraping method to coat), form the middle layer of sandstone texture after drying; specific coating twice, the second coating should be After the first coating is dried, the thickness of the intermediate layer formed after each coating is dried is 1mm;

[0081] (3) Then on the sandstone...

Embodiment 2

[0089] Such as Figure 4 Shown is the cross-sectional structure diagram of the sandstone wall surface with grid cloth attached to the wall surface of the present invention and then coated with sandstone texture texture paint, from the wall surface to the outer layer: wherein 1 is the wall surface, 5 is the grid cloth layer, 2 is the middle layer of sandstone texture, 3 is the sandstone texture finish layer, and 4 is the overcoat layer; Figure 4 The specific construction steps are as follows: after the wall surface to be constructed in the (1) step of embodiment 1 is inspected and cleaned, a layer of fiber mesh cloth is first laid, and then the (2) of embodiment 1 is carried out. -(4) step; wherein in the step (2), the texture paint is specifically coated twice, and the second coating will be carried out after the first coating is dried, and the thickness of the intermediate layer formed after each coating is dried is 1.5mm.

[0090] For the sandstone texture paint, the grad...

Embodiment 3

[0096] Such as Figure 5 Shown is a schematic diagram of the cross-sectional structure of a sandstone wall surface coated with a sandstone texture texture coating after the wall surface of the present invention is attached with a reinforcement layer, from the wall surface to the outer layer: 1 is the wall surface, 6 is the reinforcement layer, and 2 is the sandstone texture The middle layer, 3 is the sandstone texture finish layer, and 4 is the overlay layer; Figure 5 The specific construction steps are: after the wall surface to be constructed in the (1) step of embodiment 1 is inspected and cleaned, first coat mortar or putty, form a reinforcement layer after drying, and then carry out the method of embodiment 1 The first (2)-(4) step; Wherein step (2) texture coating is specifically coated 3 times, and the latter coating will be carried out after the previous coating is dried, and the intermediate layer formed after each coating is dried The thickness is 1.2mm.

[0097] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com