Waste heat recovery overall device for external exhaust of glass annealing furnace

A technology of waste heat recovery and annealing kiln, which is applied in the direction of furnace control device, steam generation method using heat carrier, waste heat treatment, etc., can solve the problems of inefficient recycling, heat energy waste, loss, etc., achieve efficient recycling and ensure product quality The effect of quality, ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

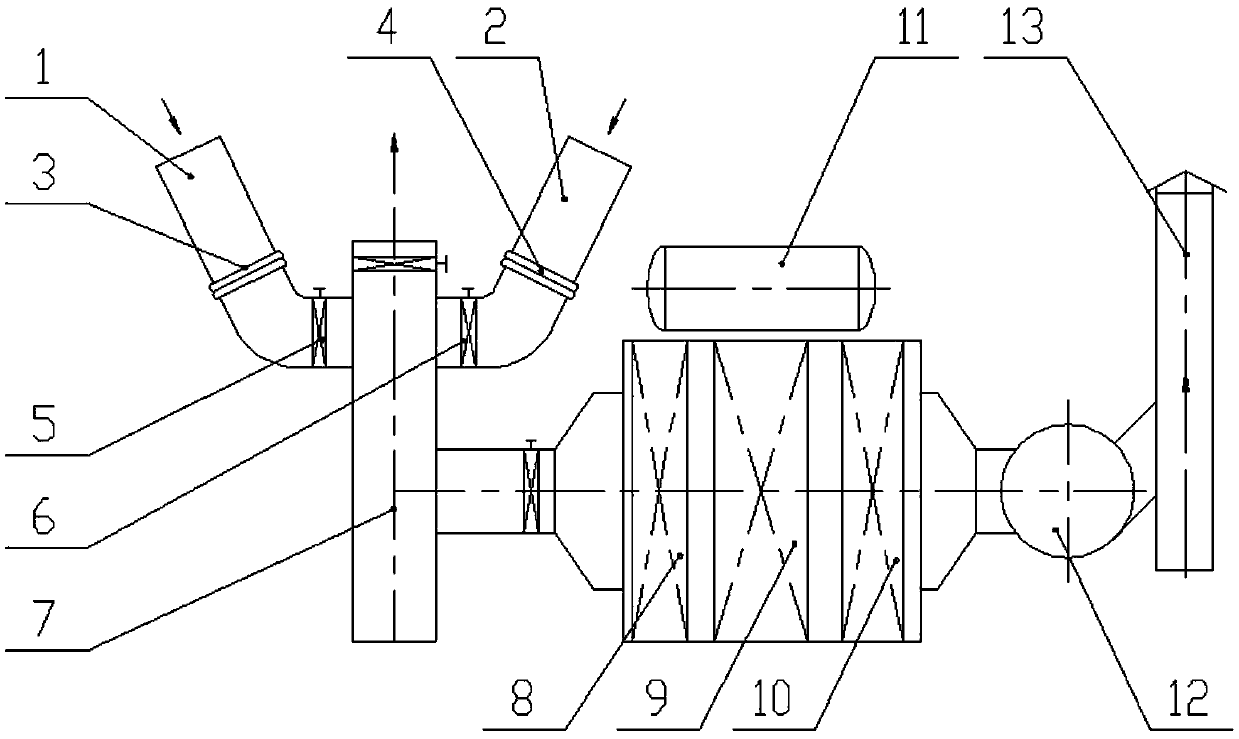

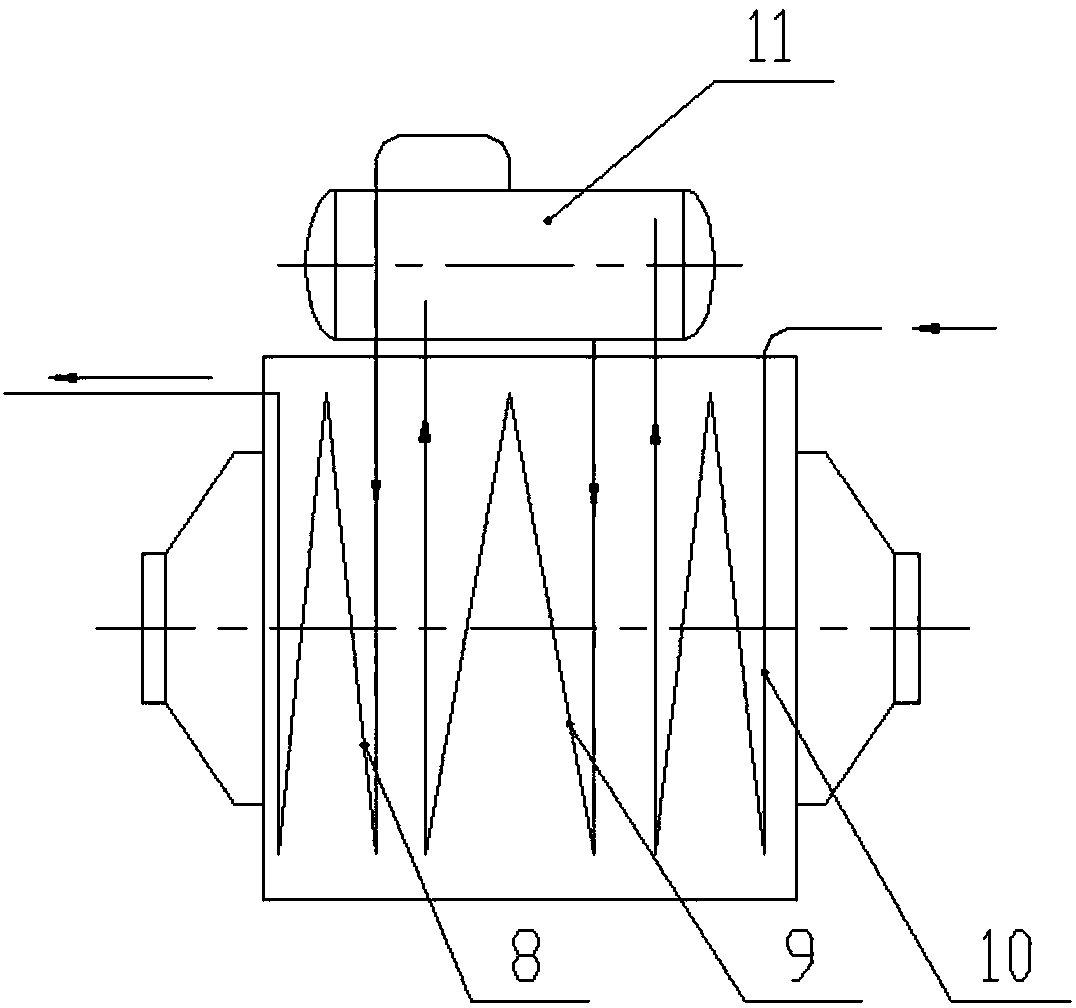

[0018] Such as Figure 1 to Figure 2 As shown, the overall device for recovering waste heat from exhaust air outside a glass annealing kiln includes inlet flue branch pipe I1, inlet flue branch pipe II2, expansion joint I3, expansion joint II4, damper I5, damper II6, inlet smoke Road main pipe 7, superheater 8, evaporator 9, economizer 10, induced draft fan 12, etc., safe and efficient recovery of exhaust air waste heat outside the annealing kiln, the overall energy-saving device can collect and disperse the heat source of exhaust air outside the annealing kiln, through the induced draft fan 12 The frequency conversion adjusts the wind pressure in the inlet flue main pipe 7, and at the same time, according to the air pressure in the inlet flue main pipe 7, the wind pressure of the inlet flue branch pipe I1 and the inlet flue branch pipe II2 can be effectively adjusted through the damper I5 and damper II6 to ensure The exhaust air and waste heat outside the annealing kiln are s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com