Three-dimensional framework and sulfonated aromatic polymer composite proton exchange membrane and preparation method thereof

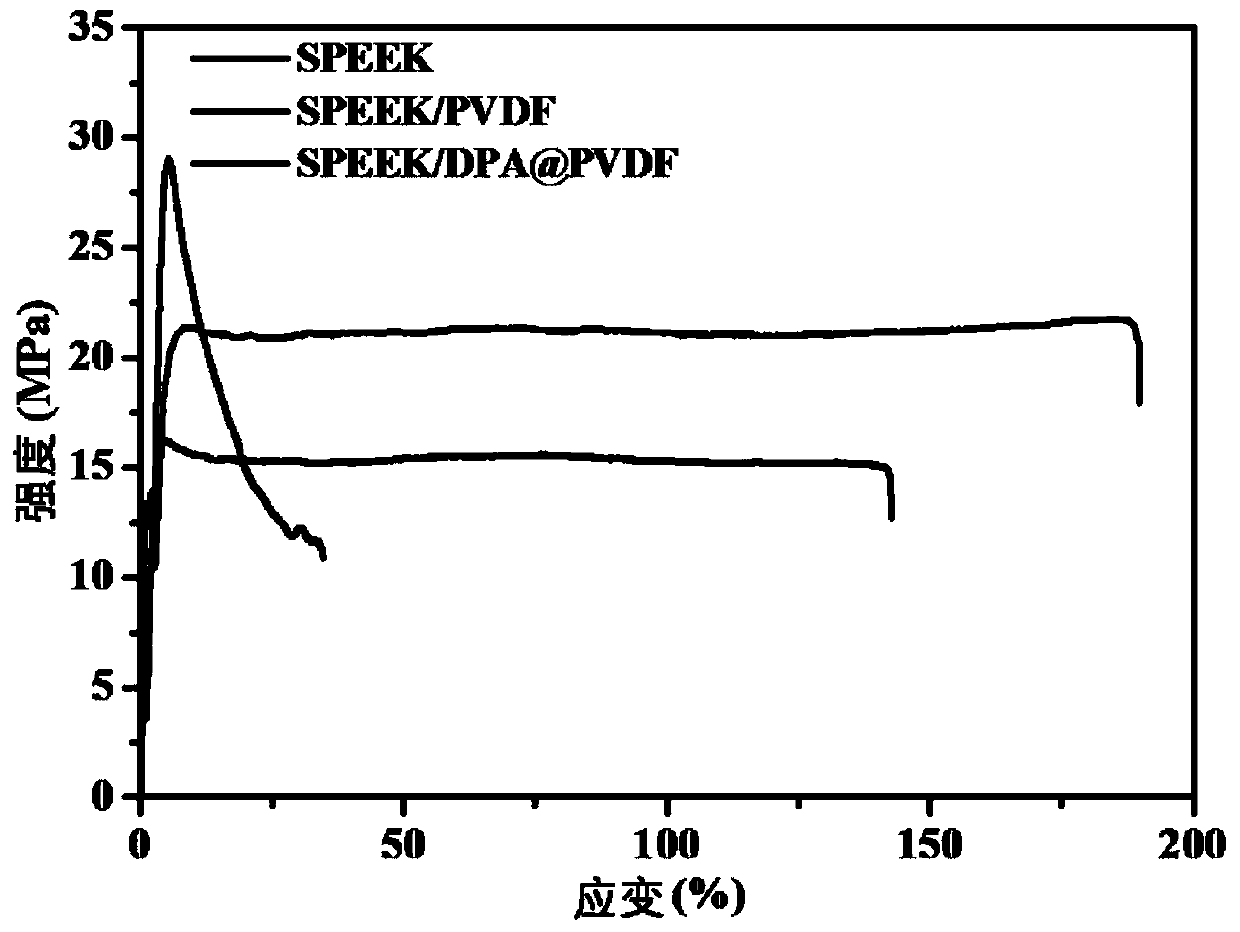

A technology of aromatic polymers and proton exchange membranes, applied in electrochemical generators, fuel cells, electrical components, etc., can solve the problem of poor spinnability of proton-conducting polymers, low degree of entanglement of polymer chains, and unfavorable large-scale production To achieve the effect of improving mechanical properties and methanol penetration resistance, inhibiting swelling, improving mechanical properties and methanol resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A preparation method of a three-dimensional skeleton and a sulfonated aromatic polymer composite proton exchange membrane, which comprises the following steps:

[0033] dissolving the sulfonated aromatic polymer in a first solvent and diluting with a second solvent;

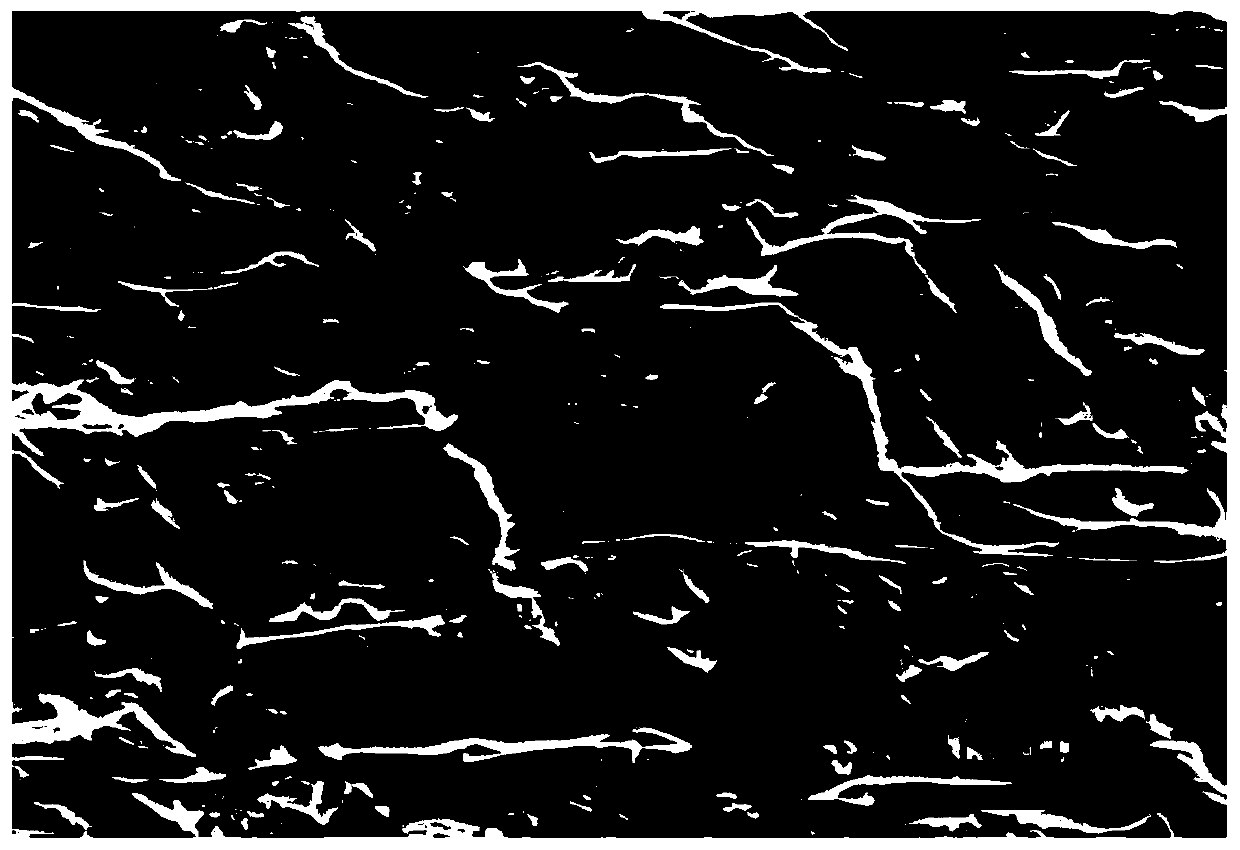

[0034] Place the polydopamine-modified three-dimensional skeleton in the casting film tank;

[0035] The sulfonated aromatic polymer solution is poured onto the polydopamine-modified three-dimensional framework and dried to obtain a three-dimensional framework / polyelectrolyte composite proton exchange membrane.

[0036] Preferably, the drying is carried out at 20-40°C, for example, at 20°C, 30°C or 40°C, so that two solvents with different boiling points are volatilized at the same time, ensuring that the sulfonated aromatic polymer is The three-dimensional skeleton is filled densely.

[0037] In the present invention, the sulfonated aromatic polymer is prepared by stirring 25g of aromatic polymer and 50...

Embodiment 1

[0049] (1) Weigh 25g of sulfonated polyaryletherketone, stir it with 500ml of sulfuric acid at 50°C for 6 hours, then slowly pour the mixture into a large amount of ice water and wash the precipitated sulfonated polyaryletherketone with deionized water repeatedly to neutrality, filtered and squeezed dry, and dried at 80°C to obtain sulfonated polyaryletherketone with a sulfonation degree of 75%;

[0050] (2) Take 0.7 g of the sulfonated polyaryletherketone obtained in step (1) and dissolve it in N,N-dimethylacetamide to form a 7wt% solution; then dilute the solution with water to a 2.5wt% solution;

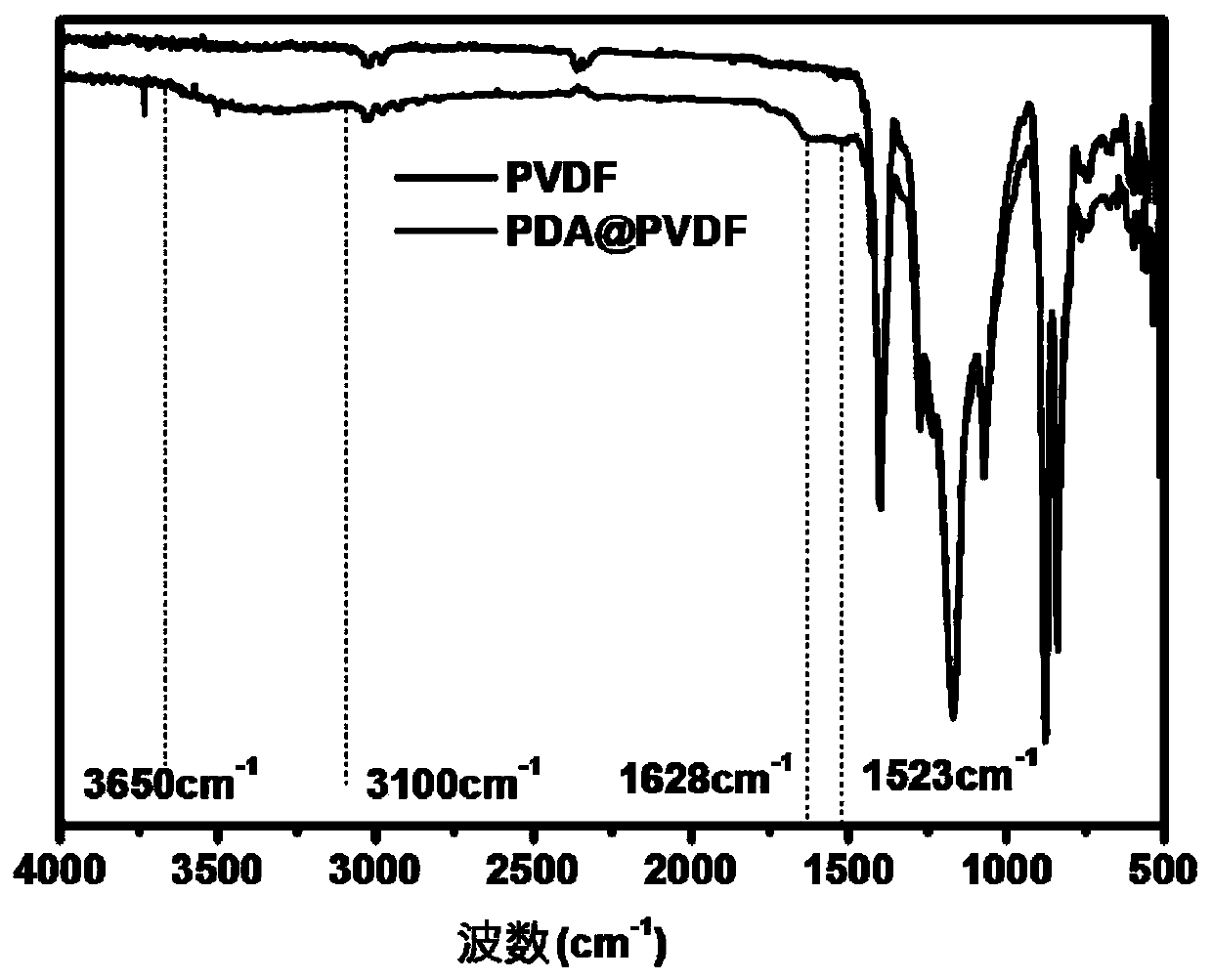

[0051] (3) Prepare an aqueous solution of triisopropylethanesulfonyl with a concentration of 0.4mmol / L; then add the electrospun polyvinylidene fluoride nanofiber membrane to the aqueous solution of triisopropylethanesulfonyl, wherein the polyvinylidene fluoride The ratio of the ethylene nanofiber membrane to the aqueous solution of triisopropylethanesulfonyl is 4g / L; finally, lev...

Embodiment 2

[0058] (1) Weigh 25g of sulfonated polyaryletherketone, stir it with 500ml of sulfuric acid at 50°C for 8 hours, then slowly pour the mixture into a large amount of ice water and wash the precipitated sulfonated polyaryletherketone with deionized water repeatedly to neutrality, filtered and squeezed dry, and dried at 80°C to obtain sulfonated polyaryletherketone with a sulfonation degree of 85%;

[0059] (2) Take 0.7 g of the sulfonated aromatic polymer obtained in step (1) and dissolve it in N,N-dimethylacetamide to form a 10wt% solution; then dilute the solution with water to a 3wt% solution;

[0060] (3) Prepare an aqueous solution of triisopropylethanesulfonyl with a concentration of 0.4mmol / L; then add the electrospun polyvinylidene fluoride nanofiber membrane to the aqueous solution of triisopropylethanesulfonyl, wherein the polyvinylidene fluoride The ratio of the ethylene nanofiber membrane to the aqueous solution of triisopropylethanesulfonyl is 4g / L; finally, levodop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap