Antibacterial reusable air purification filter net and preparation method thereof

An air purification and filter technology, applied in the field of air purification, can solve the problems of indoor air secondary pollution, short service life, affecting the use effect of consumers, etc., to prevent the penetration of particles, reduce costs, and solve indoor secondary pollution problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

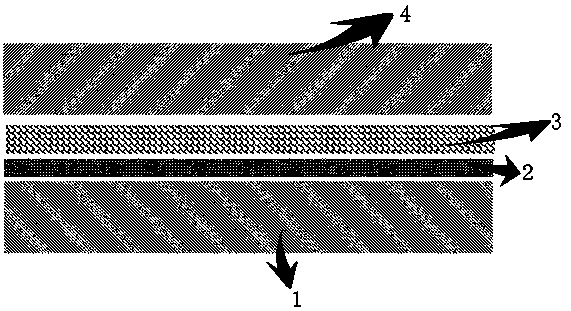

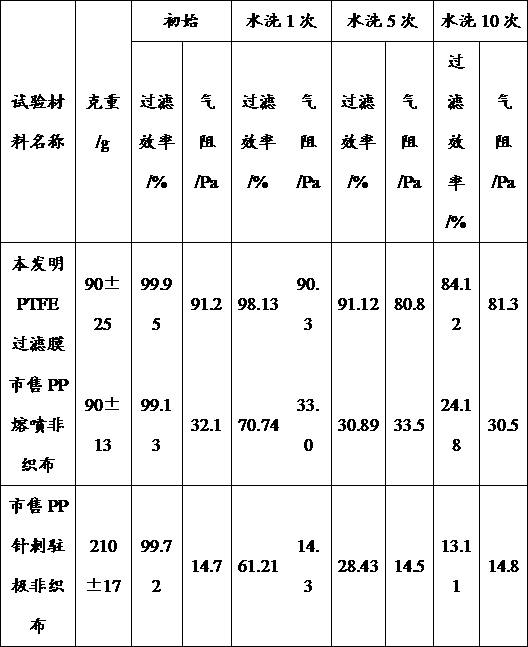

[0024] An antibacterial reusable air purification filter such as figure 1 Shown: including non-woven fiber support layer 1, filter layer 2, antibacterial layer 3 and cover layer 4, non-woven fiber support layer 1, filter layer 2, antibacterial layer 3 and cover layer 4 are hot-pressed and laminated sequentially from bottom to top; The filter layer 2 includes a PTFE filter membrane, and the antibacterial layer 3 includes a chitosan antibacterial nanofiber membrane.

[0025] In the present invention, the pore diameter of the PTFE filter membrane is 0.18 μm-0.22 μm, preferably, the pore diameter of the PTFE filter membrane is 0.20 μm, and the porosity of the PTFE filter membrane is greater than or equal to 89%. When particulate pollutants pass through the PTFE filter membrane, Particles with a particle size smaller than the pore size of the PTFE filter membrane pass through the PTFE filter membrane; particles with a particle size larger than the pore size of the PTFE filter membr...

Embodiment 2

[0029] A preparation method for an antibacterial and reusable air purification filter screen, comprising the steps of:

[0030] Preparation of PTFE filter membrane: Mix the dried PTFE powder and organic polar solution and extrude PTFE strips, calender the PTFE strips into PTFE membranes, and heat, stretch, shape and cut the PTFE membranes and winding to obtain a PTFE filter membrane.

[0031] The specific steps of preparing the PTFE filter membrane are as follows: fully dry the PTFE fine powder in an oven, fully mix the dried PTFE powder with the organic polar solution, and then enter the extruder to extrude, thereby extruding the PTFE strip, and then The PTFE strip is calendered into a membrane under a rolling machine, heated to volatilize the organic polar solution, then stretched vertically and horizontally, and then heat-treated to shape, cut and wind to obtain a biaxially stretched PTFE filter membrane. The pore diameter of the prepared PTFE filter membrane is 0.18 μm-0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com