Method for treating VOCs (Volatile Organic Compounds) exhaust gas in workshop of Baijiu industry

A waste gas treatment and workshop technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of high operation and maintenance costs, low removal efficiency, and high investment, and achieve reduced energy consumption, easy operation, and treatment efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

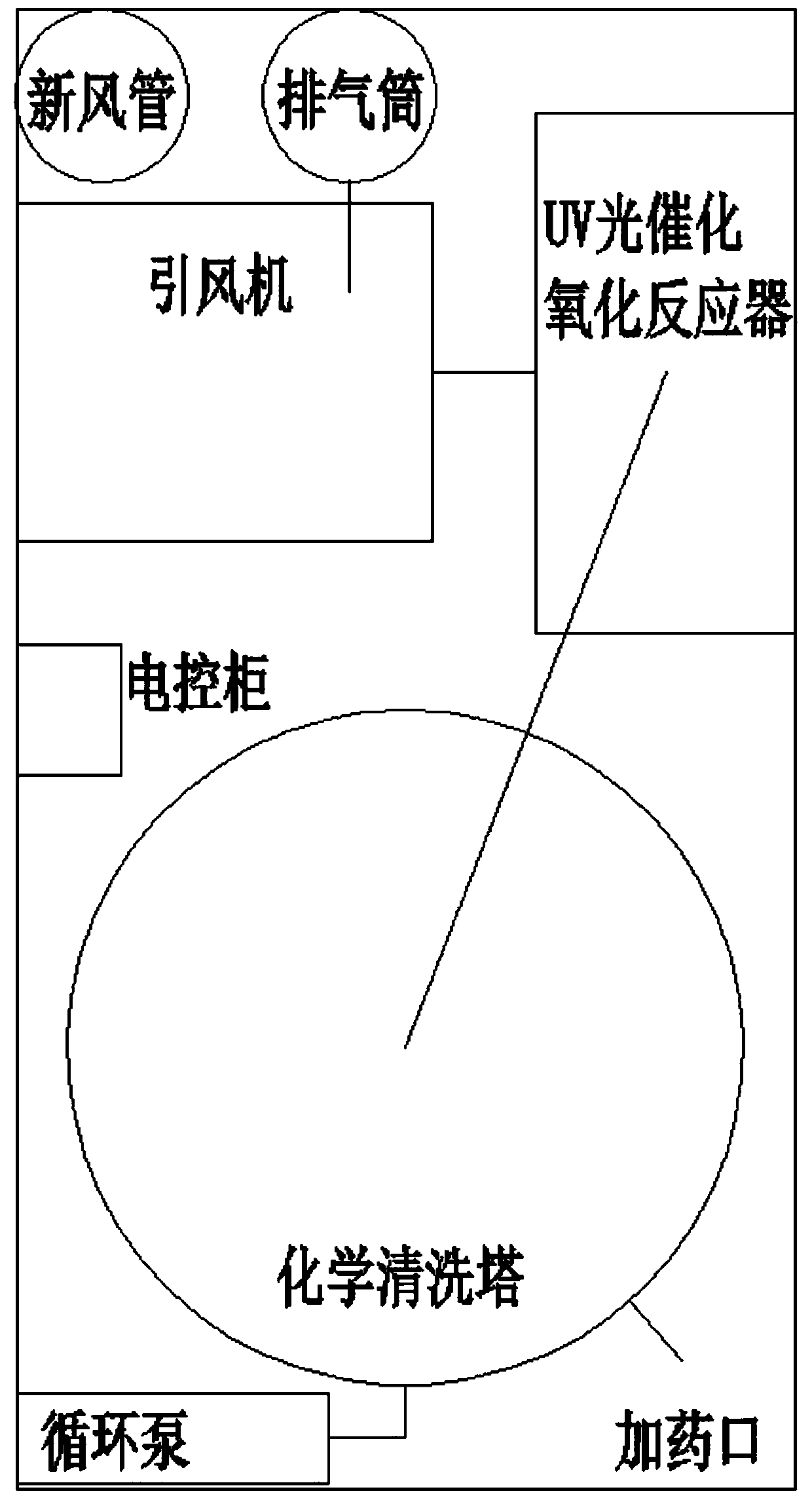

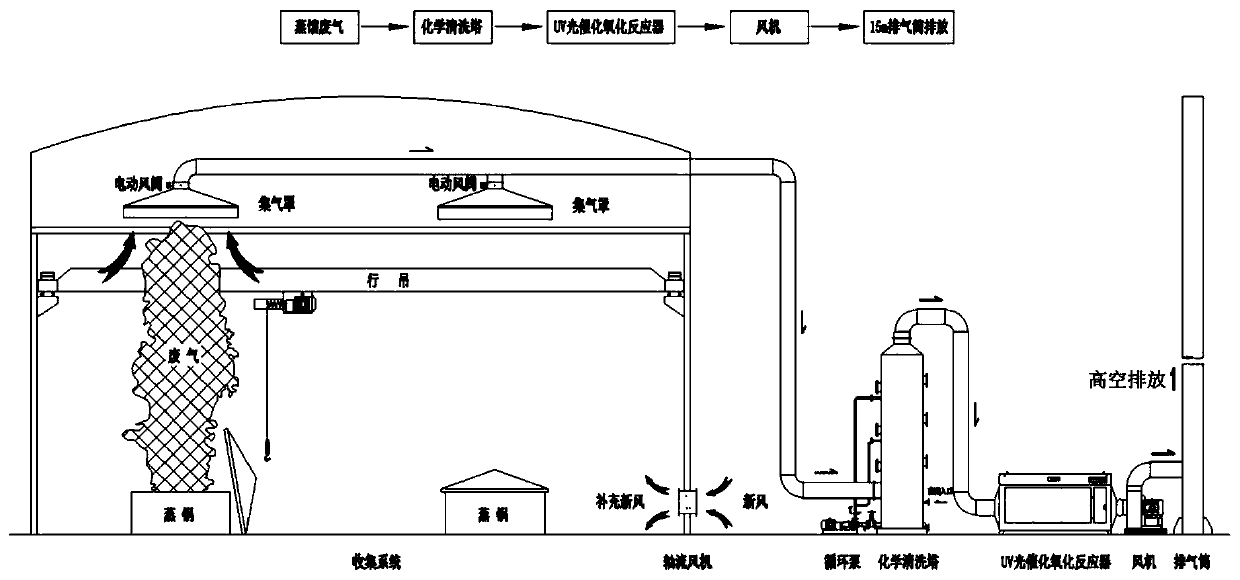

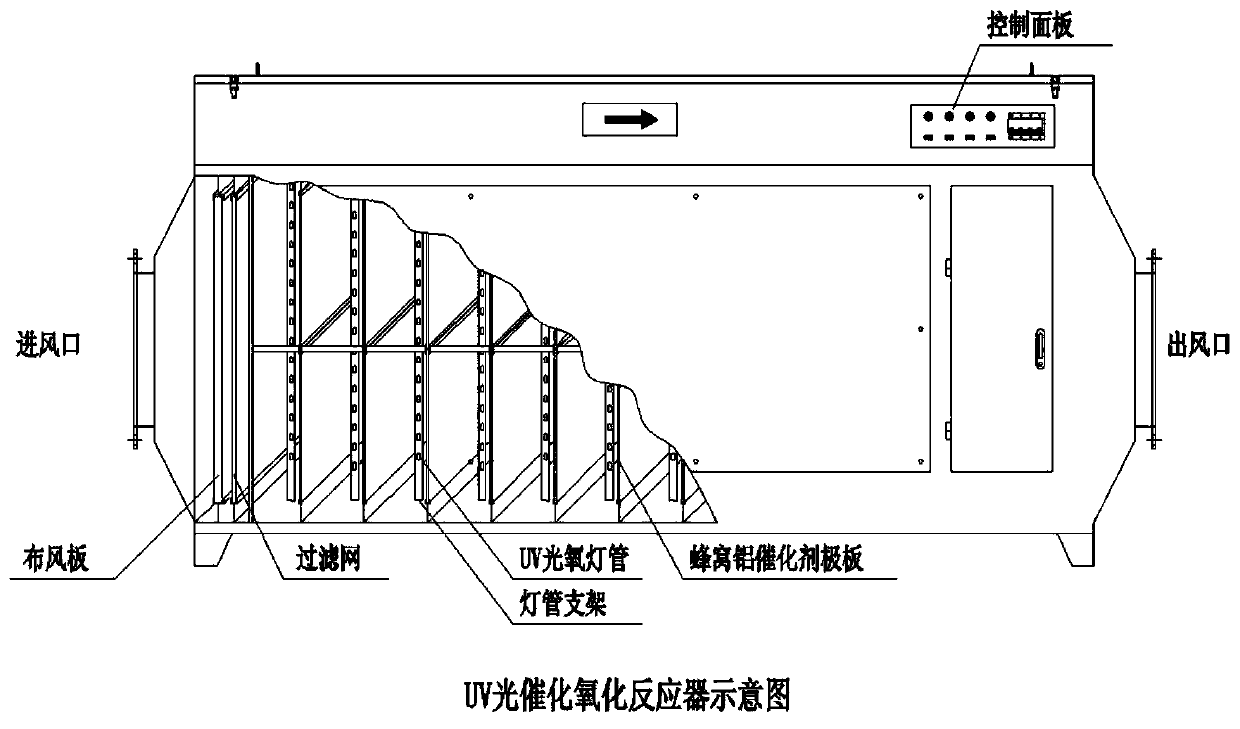

[0040] A method for treating VOCs waste gas in liquor industry workshops, comprising the following steps:

[0041] (1) An electric air valve is installed on the top of the air collecting hood of the present invention, and the electric air valve on the top of the air collecting hood above the corresponding steamer is opened to carry out point-to-point targeted collection. The gas hood and delivery pipeline are sent to the chemical cleaning tower; at the same time of suction, the fresh air is supplemented by the axial flow fan to break the negative pressure state of the closed workshop;

[0042] After the fan is turned on, the negative pressure in the recycling workshop is caused by the continuous suction of air, which is not conducive to the subsequent waste gas collection. The supplementary fresh air volume is selected according to the air volume of the terminal fan (the supplementary fresh air volume is 2 / 3 of the air volume of the terminal fan is the best), so that the worksh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com