A laser polishing method

A laser polishing and laser technology, which is applied in the field of laser polishing, can solve the problems that the chemical composition of 3D printed metal objects is not yet clear, and the absorption process is complicated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

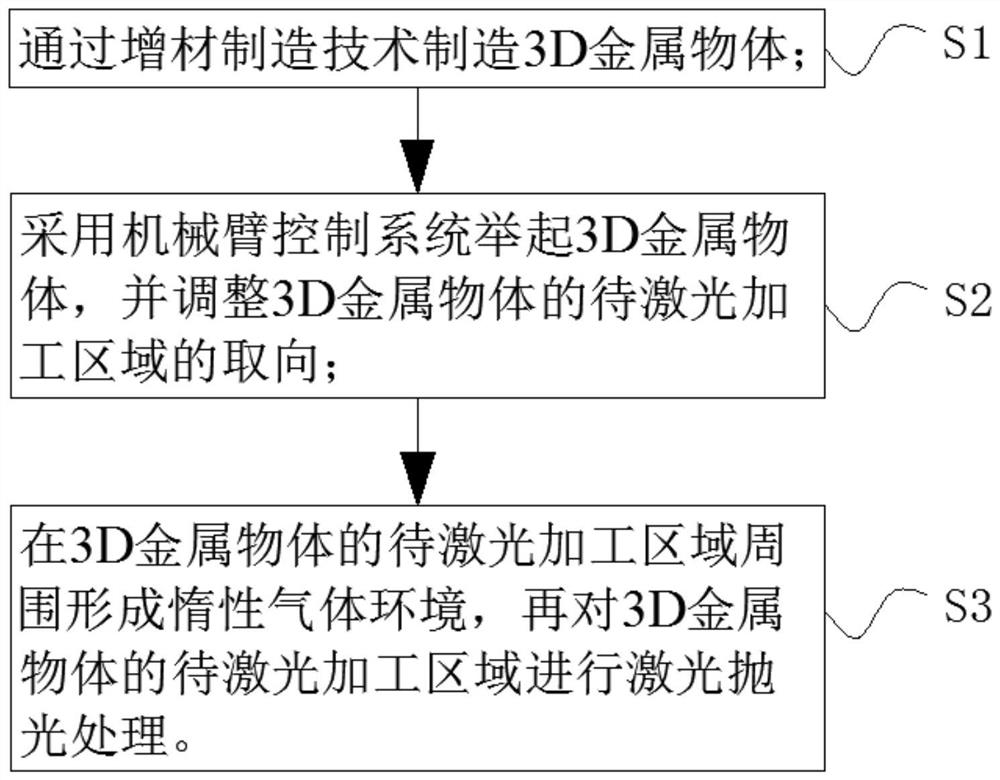

[0032] Such as figure 1 as shown, figure 1 A flowchart of a laser polishing method according to an embodiment of the present invention is shown, and the laser polishing method includes the following steps:

[0033] Step S1, manufacturing 3D metal objects by additive manufacturing technology;

[0034] Step S2, using the robotic arm control system to lift the 3D metal object, and adjust the orientation of the laser processing area of the 3D metal object;

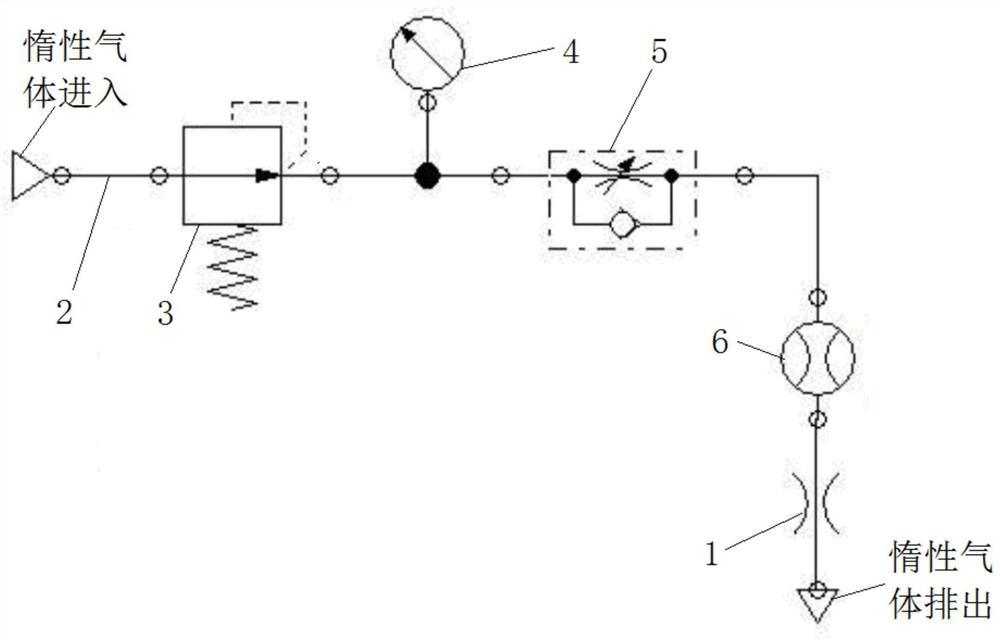

[0035] Step S3, forming an inert gas environment around the laser processing area of the 3D metal object, and then performing laser radiation on the laser processing area of the 3D metal object.

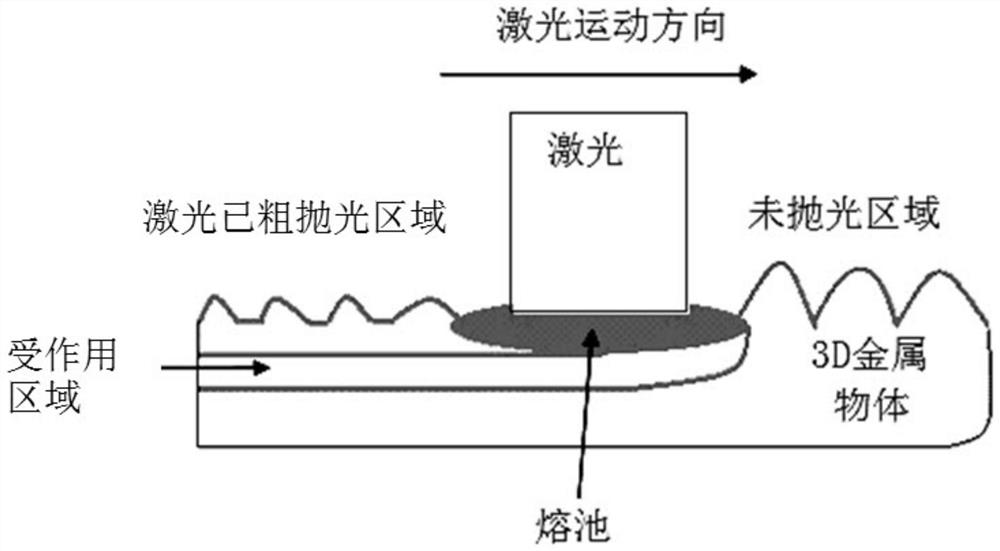

[0036] The above technical solution is a novel laser polishing technology that can effectively polish the surface of a 3D metal object manufactured by 3D printing. Polishing techniques by employing laser radiation can help to re-melt thin surface layers of 3D metal objects and can achieve smoothing of the surface roughness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com