Method for increasing matrix impact resistance of ANAMMOX granules

A technology of anaerobic ammonium oxidation and impact capacity, which is applied in anaerobic digestion treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problem of unexplored and researched, unstable denitrification performance of the system, and particle settlement Problems such as poor performance, achieve good stability and settlement performance, improve stability and settlement ability, and improve stability and settlement performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

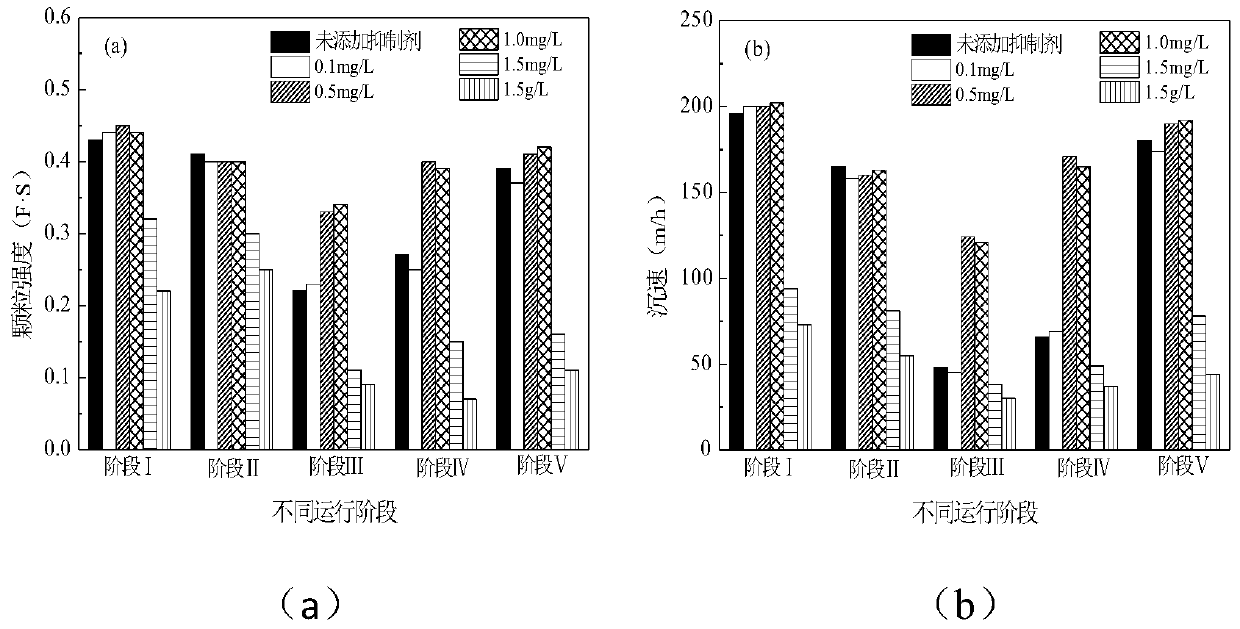

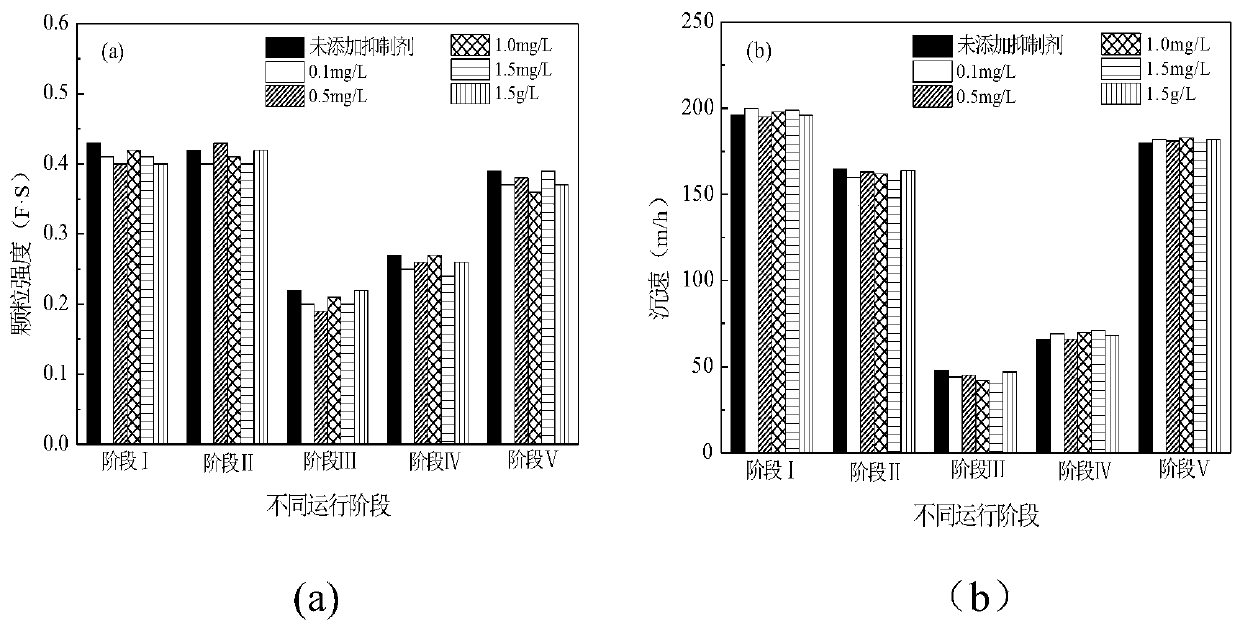

[0045] Effects of different concentrations of porcine kidney acylase I on particle stability, sedimentation performance and denitrification performance of UASB reactor under impact of matrix

[0046] Two sets of UASB reactors were set up, and after inoculation with low-load ANAMMOX granular sludge, the continuous flow experiment (divided into 5 stages) was carried out. During the stable operation period (stage I and stage II), the concentration of substrate total nitrogen (TN) increased from 122mg / L to 340mg / L, HRT remained unchanged for 2.3h, and the total nitrogen loading rate (NLR) increased from 1.3kg / (m 3 ·d) increased to 3.5kg / (m 3 d), and then perform 24h 1500-2500mg / L high-concentration TN impact, one group of UASB reactors without inhibitors, as a blank control group; Add 0.1mg / L, 0.5mg / L, 1.0mg / L, 1.5mg / L and 1.5g / L porcine kidney acylase I until the end of the shock. Afterwards, the concentration of substrate TN was reduced to 307mg / L (stage III), 143mg / L (stage I...

Embodiment 2

[0048] Embodiment 2 (i.e. comparative example):

[0049] Effects of different concentrations of vanillin on particle stability, settling performance and denitrification performance of UASB reactor under impact of matrix

[0050]Investigate the influence of different concentrations (0.1mg / L, 0.5mg / L, 1.0mg / L, 1.5mg / L, 1.5g / L) of vanillin on particle stability and sedimentation performance under matrix impact, the experimental operation steps are the same as

[0051] Example 1.

Embodiment 3

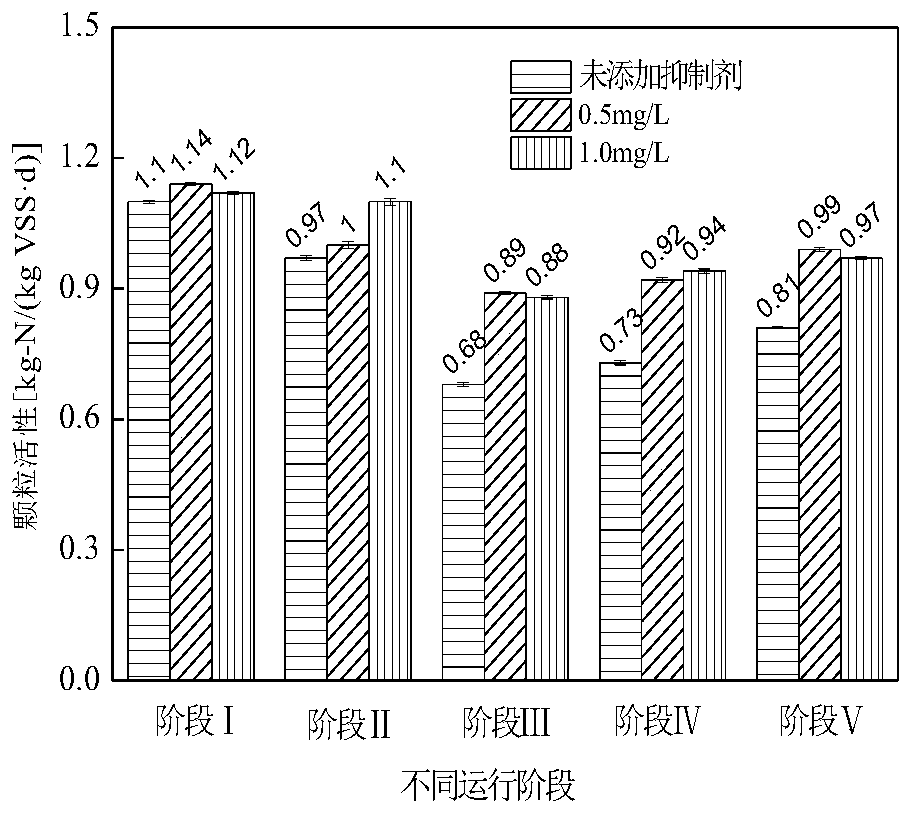

[0053] Effect of Adding Lower Concentration of Porcine Kidney Acylase I on the Activity of Granules Under Substrate Impact

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com