Harmless arsenic solidifying method for industrial wastewater containing arsenic

A wastewater and industrial technology, applied in the field of arsenic pollution control, can solve problems such as complicated processes, and achieve the effects of simple process flow, high arsenic removal and arsenic fixation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

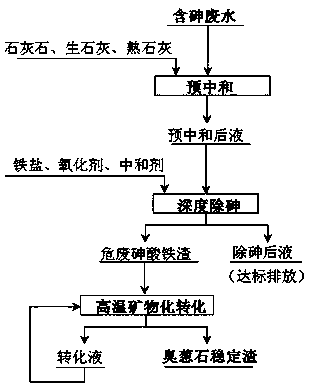

Method used

Image

Examples

Embodiment 1

[0026] A method for mineralizing and fixing arsenic in industrial arsenic-containing wastewater, the specific steps are as follows:

[0027] (1) Add 100L of industrial arsenic-containing wastewater (concentration of main substances: arsenic 8.5g / L, sulfuric acid 1.0 g / L) into the reaction tank with stirring device, and continuously add limestone until the pH of the reaction system is 10 ; After the reaction, the reaction slurry was allowed to stand for stratification to obtain 96L of neutralized liquid.

[0028] (2) Add 12.6kg of ferrous sulfate and 5.5L of hydrogen peroxide to the 96L of neutralized solution in step (1) according to the molar ratio of iron to arsenic of 4:1, to carry out deep arsenic removal, and continuously add limestone during the process to maintain The pH of the reaction system is 6; when the arsenic content in the reaction system is less than 0.5 mg / L, the reaction slurry is subjected to liquid-solid separation to obtain 2.8 kg of iron arsenate arsenic ...

Embodiment 2

[0032] A method for mineralizing and fixing arsenic in industrial arsenic-containing wastewater, the specific steps are as follows:

[0033] (1) Add 100L of industrial arsenic-containing wastewater (concentration of main substances: arsenic 15g / L, sulfuric acid 40g / L) into a reaction tank with a stirring device, and continuously add slaked lime until the pH of the reaction system is 8; After the end, the reaction slurry was left to stand for stratification to obtain 90L of neutralized liquid.

[0034] (2) According to the molar ratio of iron and arsenic as 6:1, add 2.4kg of ferric sulfate and bleaching powder to the 90L neutralized liquid in step (1) to remove arsenic in depth, and continuously add slaked lime during the process to maintain the stability of the reaction system. The pH is 5; when the arsenic content in the reaction system is less than 0.5mg / L, the reaction slurry is subjected to liquid-solid separation to obtain 6.3kg of iron arsenate arsenic precipitation slag...

Embodiment 3

[0038] A method for mineralizing and fixing arsenic in industrial arsenic-containing wastewater, the specific steps are as follows:

[0039] (1) Add 100L of industrial arsenic-containing wastewater (concentration of main substances: arsenic 1g / L, sulfuric acid 80g / L) into a reaction tank with a stirring device, and continuously add quicklime and slaked lime until the pH of the reaction system is 9 ; After the reaction, the reaction slurry was left to stand for stratification to obtain 84L of neutralized liquid.

[0040] (2) According to the molar ratio of iron to arsenic of 2:1, add 0.45 kg of ferric chloride to the 84 L of neutralized liquid in step (1) and pass in air to carry out deep arsenic removal. During the process, quicklime and Slaked lime keeps the pH of the reaction system at 8; when the arsenic content in the reaction system is less than 0.5 mg / L, the reaction slurry is subjected to liquid-solid separation to obtain 0.4 kg of iron arsenate arsenic precipitation sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com