Treatment method for synthesis and fermentation type pharmacy industrial sewage

A sewage treatment method, a technology of the pharmaceutical industry, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, natural water treatment, etc., can solve the problem of single process means, poor biodegradability, cellulose, lignin Low material removal efficiency and other issues, to achieve the effect of low water loss and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention.

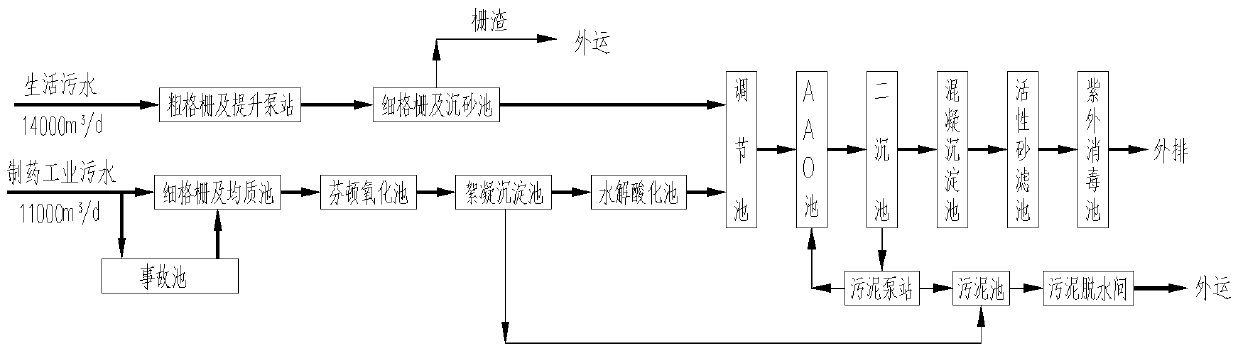

[0045] A synthetic and fermented pharmaceutical industrial sewage treatment method of the present invention is based on the synthetic and fermented pharmaceutical industrial sewage treatment system, the system includes park domestic sewage pipelines, park production sewage pipelines, regulating pools, 2 / O tank, secondary settling tank, coagulation sedimentation tank, active sand filter and ultraviolet disinfection tank; the domestic sewage pipeline in the park is equipped with a lifting pump station and a grit chamber; Dayton oxidation tank, flocculation sedimentation tank and hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com