Method for removing propane before cracking of naphtha and propane to be coupled with PHD

A naphtha and depropanization technology, which is applied in the direction of chemical instruments and methods, hydrocarbons, hydrocarbons, etc., can solve the problems of poor ability to respond to market changes, unreasonable product structure, and single raw material structure, so as to avoid raw material Risk of cost, good technical effect and economic benefit, effect of short technological process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

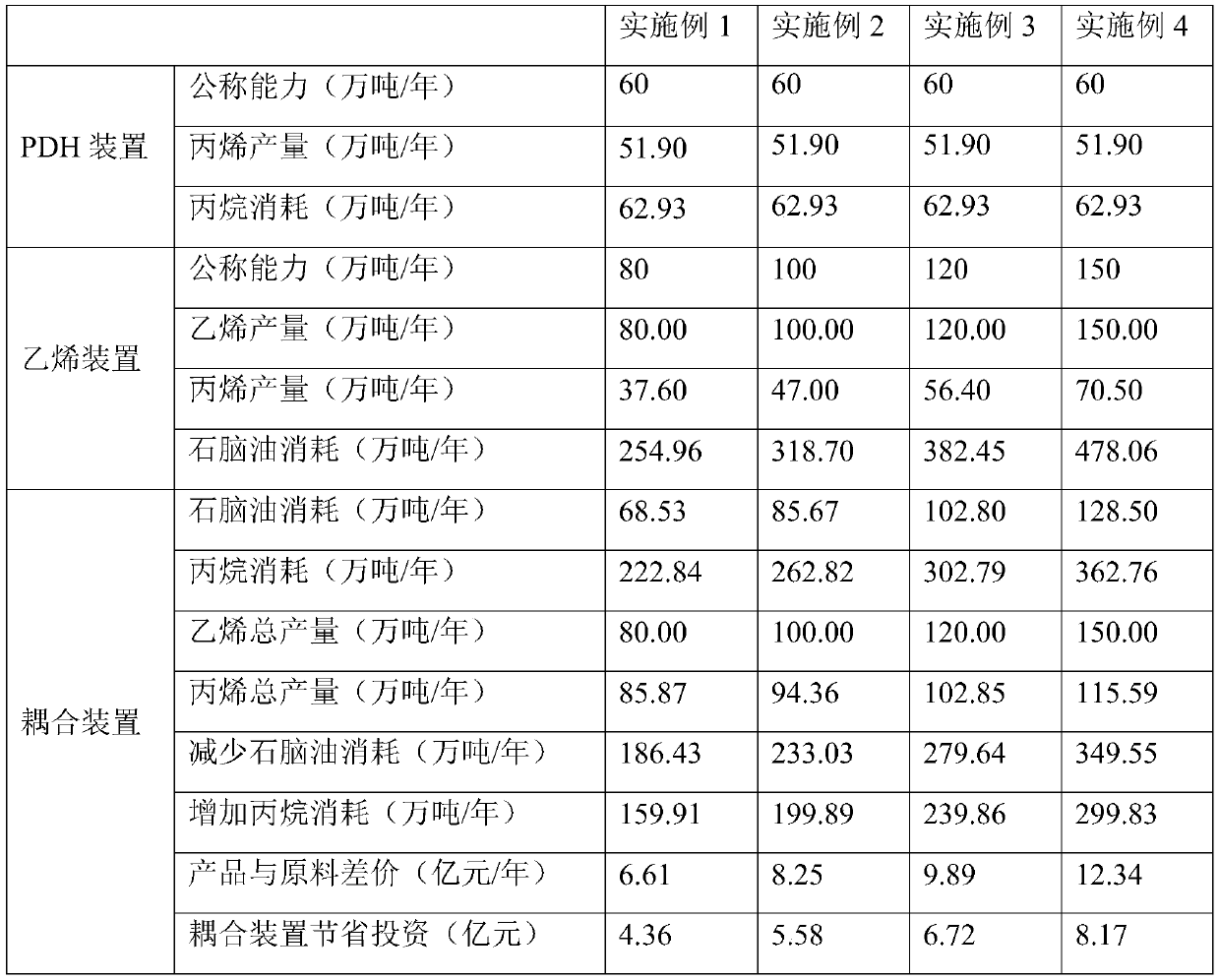

[0021] Adopt the method that depropanization and PDH couple before a kind of naphtha and propane cracking of the present invention, technological process is as follows:

[0022] (1) Ethylene plant reaction system: cracking raw materials naphtha and propane enter the steam thermal cracking unit, and are cracked in the ethylene cracking furnace into cracked gas mixed with hydrocarbons and sent to the quenching unit. After the pyrolysis gas is quenched and washed in the quenching unit, the pyrolysis gasoline and pyrolysis fuel oil are sent out of the boundary as by-products, and the rest of the pyrolysis gas is sent to the compression and alkali cleaning unit for compression, alkali washing, and drying, and then sent to the downstream separation system.

[0023] (2) Reaction system of PDH unit: fresh propane raw material is mixed with the circulating propane raw material from the bottom of the propylene rectification tower and the top material of the deoiling tower, and then enter...

Embodiment 2

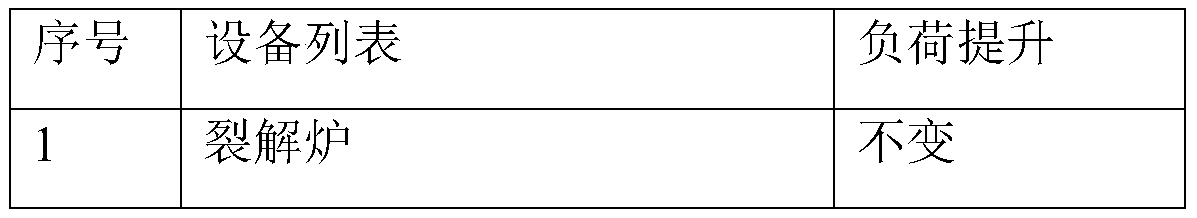

[0033] The ethylene unit of the present invention still adopts the pre-depropanization separation process, and uses naphtha and propane as cracking raw materials. The nominal capacity of ethylene is 1 million tons / year, and the nominal capacity of PDH unit is 600,000 tons / year. After adopting the integrated coupling method of the present invention, the load of the ethylene plant equipment is increased, as shown in Table 2.

[0034] Table 2 Lifting load list of ethylene plant equipment after integration

[0035] serial number

[0036] After adopting the integrated coupling method of the present invention, the polymer grade ethylene is more than 99.95 wt%, and the ethylene output is 1,000,000 tons / year; the polymer grade propylene is more than 99.6 wt%, and the propylene output is 943,600 tons / year. Compared with Comparative Example 2, the consumption of naphtha is saved by 2.3303 million tons per year, the consumption of propane is increased by 1.9989 million tons per...

Embodiment 3

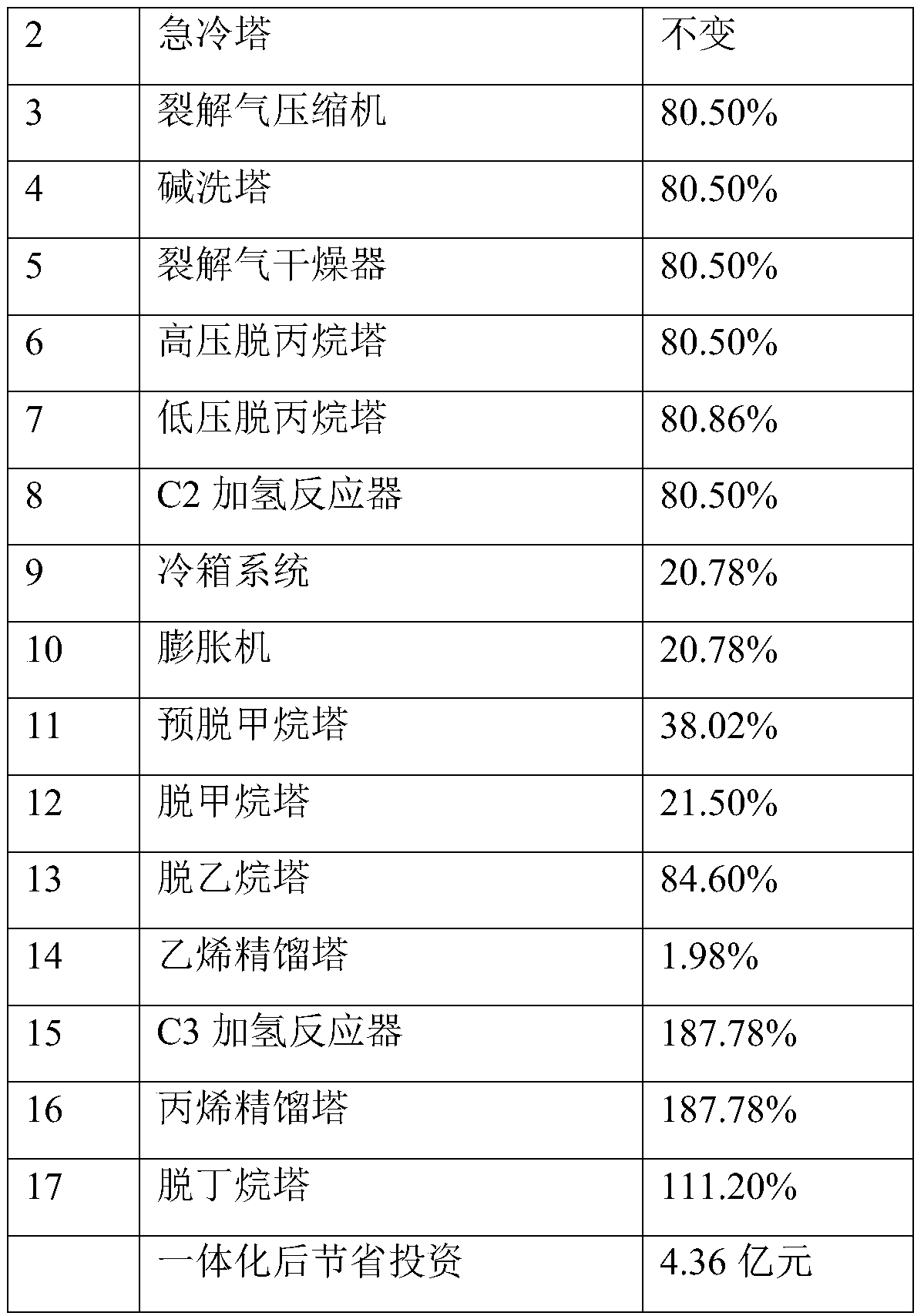

[0040] The ethylene unit of the present invention still adopts the pre-depropanization separation process, and uses naphtha and propane as cracking raw materials. The nominal capacity of ethylene is 1.2 million tons / year, and the nominal capacity of PDH unit is 600,000 tons / year. After adopting the integrated coupling method of the present invention, the load of the ethylene plant equipment is increased, as shown in Table 3.

[0041] Table 3 Lifting load table of ethylene plant equipment after integration

[0042] serial number

[0043] After adopting the integrated coupling method of the present invention, the polymer grade ethylene is ≥99.95 wt%, and the ethylene output is 1.20 million tons / year; the polymer grade propylene is ≥99.6 wt%, and the propylene output is 1,028,500 tons / year. Compared with Comparative Example 3, the consumption of naphtha is saved by 2.7964 million tons per year, the consumption of propane is increased by 2.3986 million tons per year, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com