Anticorrosive coating with barrier property

A technology of anti-corrosion coatings and barrier properties, applied in anti-corrosion coatings, coatings, etc., can solve the problems of limited application range of anti-corrosion ability, increased difficulty of spraying technology, and insufficient barrier performance, so as to achieve good compatibility and dispersion, Improved surface hydrophobicity and improved anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

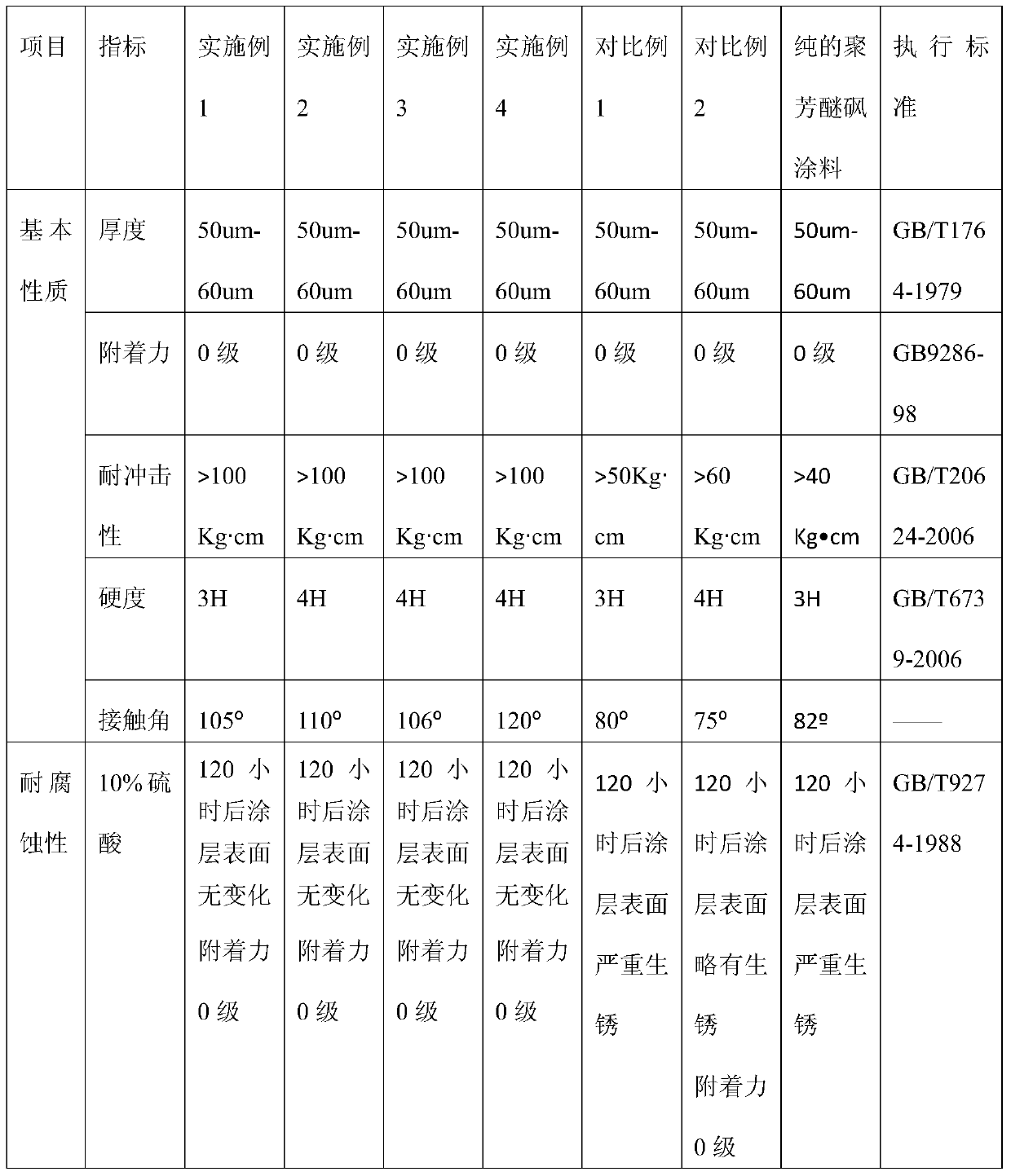

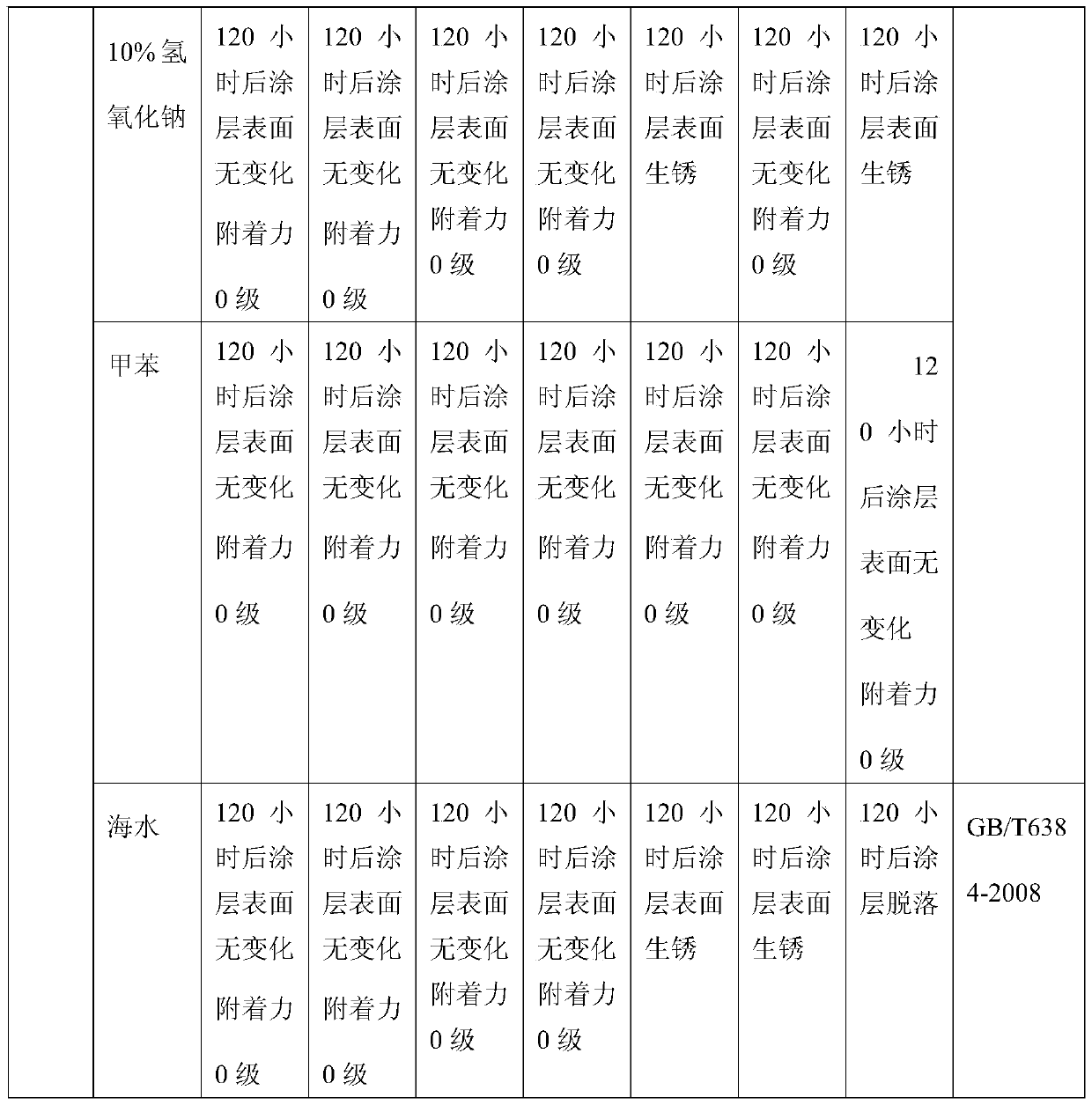

Examples

preparation example Construction

[0026] The two-dimensional ultrathin nano-TiO 2 The preparation method of sheet, comprising:

[0027] Under the protection of nitrogen, add titanium tetrachloride to ethylene glycol, heat to reflux, and then add water to react. After the reaction, cool down to room temperature, centrifuge and wash to obtain two-dimensional ultra-thin nano-TiO 2 sheet; the reaction time is preferably 30min-5h; more preferably 2-4h, the volume ratio of ethylene glycol and titanium tetrachloride is preferably (5-100): 1, more preferably (5- 6): 1, the volume ratio of titanium tetrachloride to water is preferably (1-4): 1, more preferably (1-1.25): 1; the ethylene glycol is used as a directing agent;

[0028] According to the present invention, the defoamer is preferably one or both of BYK 057, EL2600, and EL2609; the leveling agent is preferably one or both of BYK306, EL2503, and EL2537; the The dispersant is preferably one or both of BYK110, EL2310, and EL2311; the adhesion promoter is prefera...

Embodiment 1

[0032] Under the protection of nitrogen, add 0.5L titanium tetrachloride to 3.0L ethylene glycol, heat to reflux, add 0.5L water to react with titanium tetrachloride, react for 2.0h, cool down to room temperature, and perform centrifugation and washing. Two-dimensional ultrathin nano-TiO 2 Sheets (two-dimensional nano-TiO 2 The sheet thickness is 20nm, and the nanosheet is broadened by 200nm). Dissolve 90 parts of polyarylethersulfone coating (viscosity of 0.84Pa·s) in DMAC, and keep stirring to form a homogeneous solution with a solid content of 50%, two-dimensional nano-TiO 2 Add 2 parts of silane coupling agent KH550 to 6 parts of the sheet and react at 70°C for 4 hours. After wet surface modification (modified two-dimensional nano-TiO 2 The sheet thickness is 20nm, the nanosheet width is 200nm), dispersed in DMAC, ultrasonically dispersed, the above two solutions are mixed and stirred evenly at high speed, and the leveling agent BYK306: 0.5 parts, the dispersant BYK110: ...

Embodiment 2

[0036] Under the protection of nitrogen, add 0.5L titanium tetrachloride to 3.0L ethylene glycol, heat to reflux, add 0.5L water to react with titanium tetrachloride, react for 2.0h, cool down to room temperature, and perform centrifugation and washing. Two-dimensional ultrathin nano-TiO2 Sheets (two-dimensional nano-TiO 2 The sheet thickness is 20nm, and the nanosheet is broadened by 200nm).

[0037] Dissolve 80 parts of polyarylethersulfone coating (viscosity: 0.84Pa·s) in DMAC, and keep stirring to form a homogeneous solution with a solid content of 50%, two-dimensional nano-TiO 2 Add 6 parts of silane coupling agent KH550 to 12 parts of the sheet and react at 70 °C for 4 hours. After wet surface modification (modified two-dimensional nano-TiO 2 Thickness of sheet is 20nm, width of nanosheet is 200nm), dispersed in DMAC, ultrasonically dispersed, mix the above two solutions and stir evenly at high speed, add leveling agent EL2503: 0.5 part, dispersant EL2310: 0.1 part, fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com