Preparation method and use method of silk protein environment stimulation response actuator

A technology that responds to environmental stimuli and silk protein, which is applied in animal fibers, textiles, papermaking, and fiber processing, to achieve green processes, good results, and protection of crystal structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

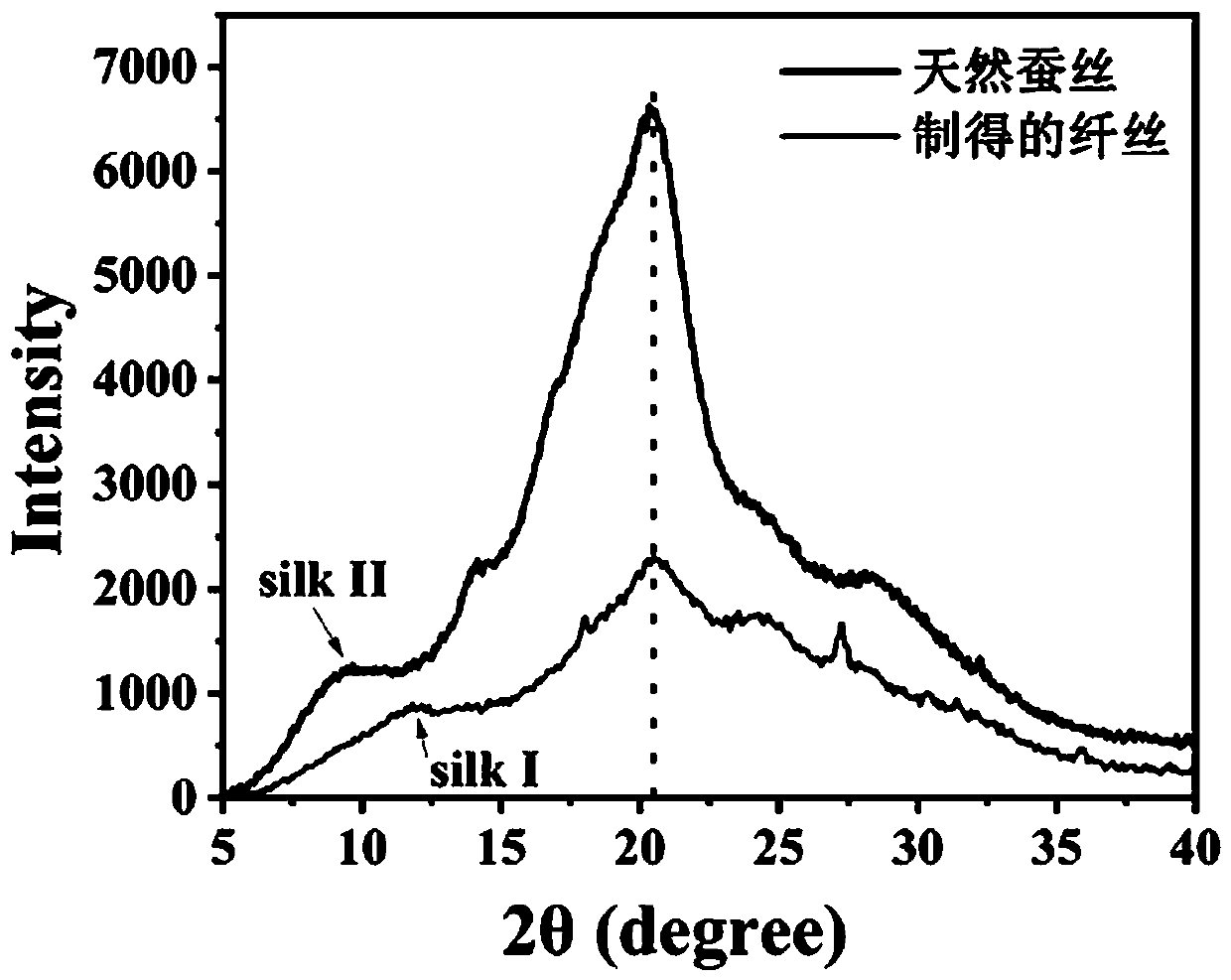

Embodiment 1

[0026] The mulberry silk fibroin fiber is dispersed in the deep eutectic solvent of urea-choline chloride, wherein the molar ratio of urea and choline chloride is 5:1, and the mass ratio of silk fibroin fiber and deep eutectic solvent is 1:20; then the silk fibroin fibers are stripped into fibrils by heating and stirring, the temperature of the silk fibroin fibers treated with the deep eutectic solvent is 80°C, and the treatment time is 3h; the prepared deep eutectic solvent- The fibril dispersion system is put into a dialysis bag and dialyzed in distilled water, and then the dialysate is concentrated in polyvinyl alcohol. The molecular weight cut-off of the dialysis bag for dialysis deep eutectic solvent is 10000, and the used for concentrating the fibril dialysate The molecular weight of polyvinyl alcohol is 8000, and the concentration of the fibril after concentration is 1wt%; the fibril concentrate in step (2) is evaporated and self-assembled, and the thickness of the conce...

Embodiment 2

[0029]The mulberry silk fibroin fiber is dispersed in the urea-choline chloride deep eutectic depth solvent, wherein the mol ratio of urea and choline chloride is 10:1, and the mass ratio of the silk fibroin fiber and the deep eutectic depth solvent is 1:40; then the silk fibroin fibers are stripped into fibrils by heating and stirring, the temperature of the silk fibroin fibers treated with the deep eutectic solvent is 100°C, and the treatment time is 24h; the prepared deep eutectic solvent- The fibril dispersion system is put into a dialysis bag and dialyzed in distilled water, and then the dialysate is concentrated in polyvinyl alcohol. The molecular weight cut-off of the dialysis bag for dialysis deep eutectic solvent is 14000, and the used for concentrating the fibril dialysate The molecular weight of polyvinyl alcohol is 10000, and the concentration of the fibrils after concentration is 2wt%; the fibril concentrate in step (2) is evaporated and self-assembled, and the thi...

Embodiment 3

[0032] Disperse tussah silk fibroin fibers in thiourea-choline chloride deep eutectic solvent, wherein the molar ratio of thiourea to choline chloride is 8:1, and the mass ratio of silk fibroin fiber to deep eutectic solvent The temperature is 1:30; then the silk fibroin fibers are stripped into fibrils by heating and stirring, the temperature of the deep eutectic solvent treatment silk fibroin fibers is 90 ° C, and the treatment time is 6h; the prepared deep eutectic solvent -Put the fibril dispersion system into a dialysis bag and dialyze in distilled water, and then put the dialysate into polyvinyl alcohol for concentration. The dialysis bag for dialysis deep eutectic solvent has a molecular weight cut-off of 14000, which is used to concentrate the fibril dialysate The molecular weight of the polyvinyl alcohol is 10000, and the concentration of the fibrils after concentration is 1.5wt%; the fibril concentrate in step (2) is evaporated and self-assembled, and the thickness of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com