High isolation and high contraction film using polyvinyl alcohol as intermediate layer and preparation method thereof

A polyvinyl alcohol and high-barrier technology, applied in the field of plastic molding materials, can solve the problems of high manufacturing cost, inability to pack, and inability to absorb the environment, and achieve the effect of good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

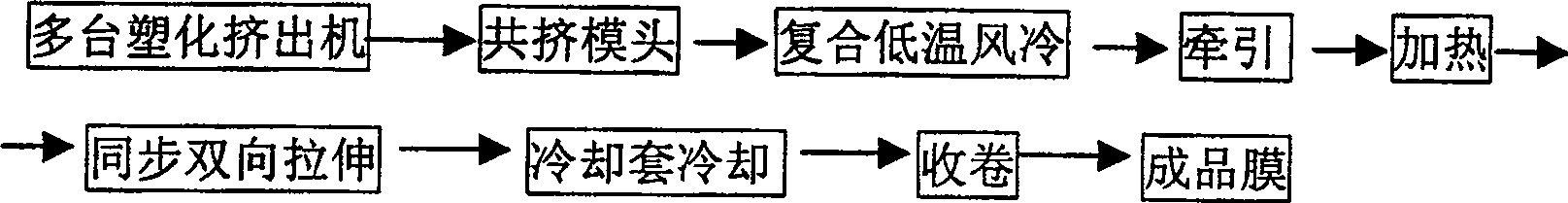

[0015] Such as figure 1 As shown, the high-barrier high-shrinkage film with polyvinyl alcohol as the middle layer and the preparation method thereof include the following steps. The method is carried out by using multiple plasticizing extruders. First, according to the structural requirements of different layers of the film, That is, the requirements of the three-layer or five-layer or seven-layer structure, the materials of each layer, such as polyolefin resin, polyvinyl alcohol, adhesive, polyamide, are put into the extruder, and passed through the co-extrusion die, composite low-temperature air cooling, Traction, heating, synchronous biaxial stretching, that is, flat extrusion top blowing biaxial stretching process, cooling jacket cooling, and winding process to make the finished film. The cooling temperature is 5°C-30°C, the temperature for heating the biaxially stretched mold body is 65-120°C, and the aspect ratio is 1:3.0-5. In the high-barrier and high-shrinkage film, ...

Embodiment 1

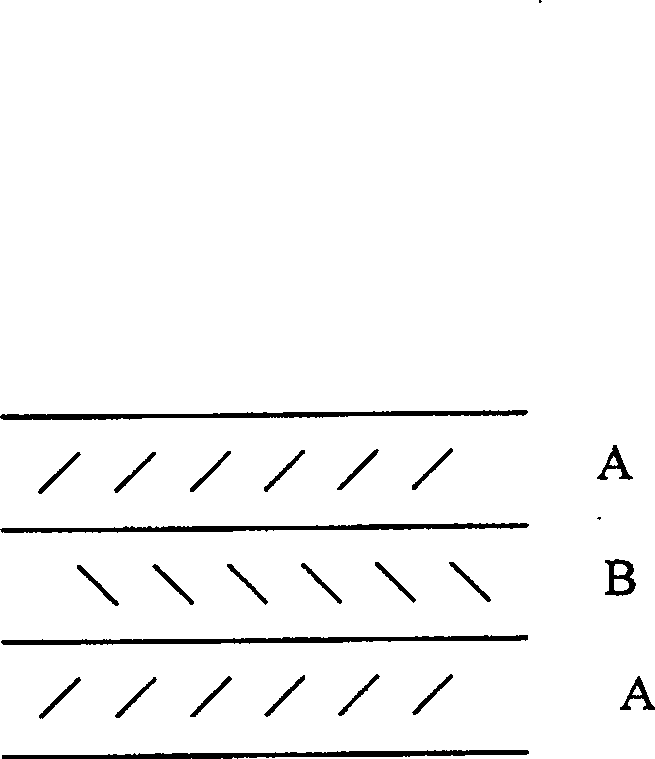

[0021] see figure 2 , in multiple plasticizing extruders A / B / A, layer A is polyolefin resin, choose 1F7A or 1F7B low-density polyethylene produced by Yanshan Petrochemical, and add 1% modified degradable additive or The polyamide resin material and the B layer are polyvinyl alcohol (PVA) special materials, which are respectively put into the required extruders according to the film thickness percentages of 30% / 40% / 30%, and are completed through the co-extrusion die head process.

Embodiment 2

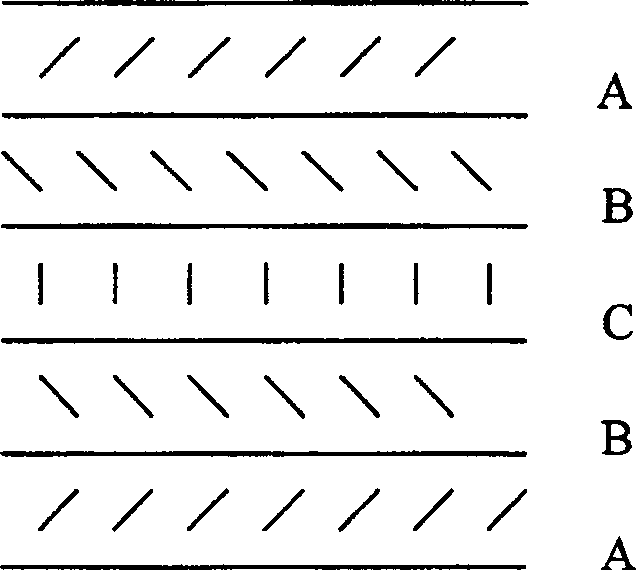

[0023] see image 3 , in multiple plasticizing extruders A / B / C / B / A, the A layer is polyolefin resin, and the 1C7A low-density polyethylene produced by Yanshan Petrochemical is selected, and the modified degradable additive or matrix is added. 0.5% of the material is stirred evenly, the B layer is a modified bonding resin (or adopting the 528H resin of Mitsui & Co., Ltd.), and the C layer is a PVA resin, which is extruded through a co-extrusion die to obtain the required film, and the thickness percentage is respectively: 10 % / 20% / 40% / 20% / 10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com