1064nm laser

A laser and optical path technology, applied in the direction of lasers, laser parts, laser parts, etc., can solve the problems of fragility, unstable resonator, low beam quality, etc., to facilitate transportation and storage, reduce floor space, shorten The effect of overall length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

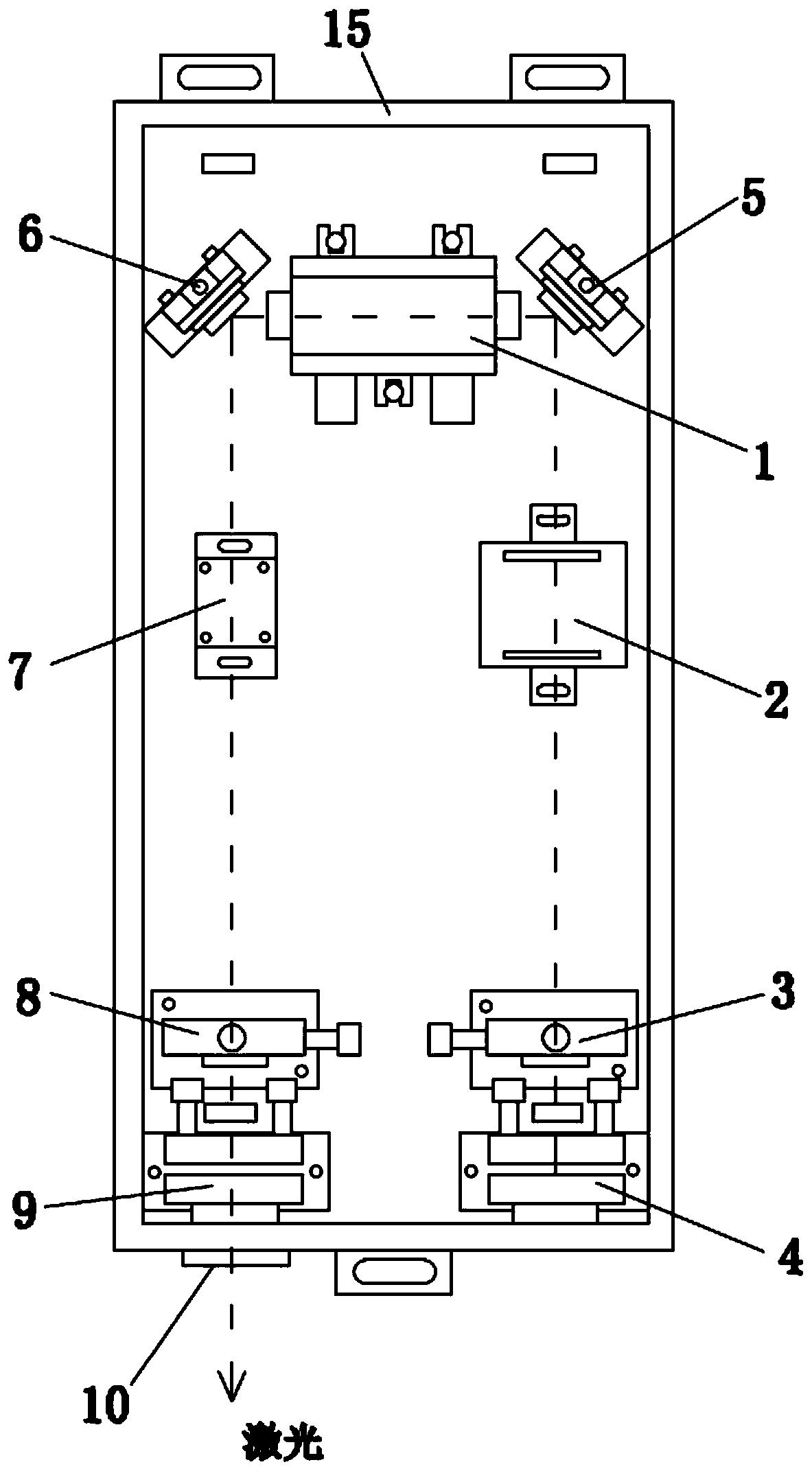

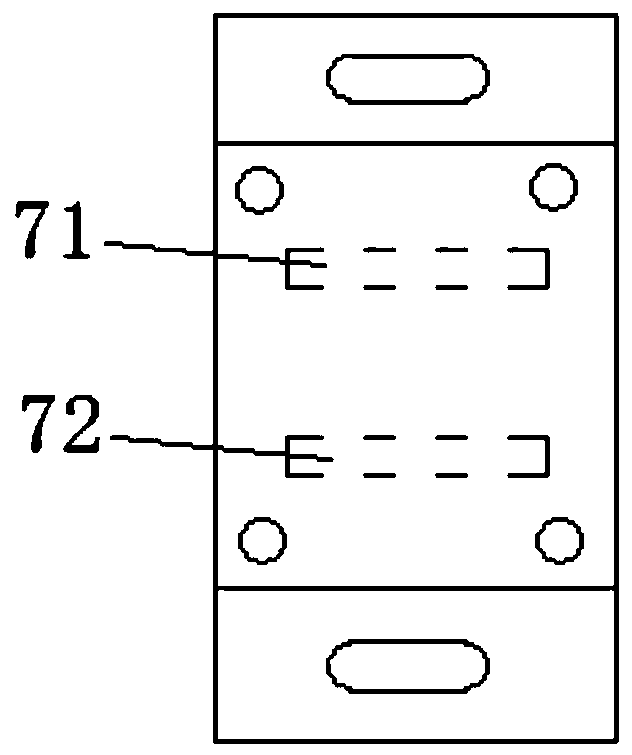

[0023] The specific embodiment of the present invention is as figure 1 and figure 2 As shown, a 1064nm laser includes a housing 15, which includes a semiconductor side pump module 1, and the semiconductor side pump module 1 can emit 1064nm laser, but due to the low quality of the emitted laser light, the slave laser Corresponding treatment is required before injection. The semiconductor side pump module 1 is provided with a first optical path output end and a second optical path output end; outside the first optical path output end of the semiconductor side pump module 1, an acousto-optic switch 2, a first aperture diaphragm 3 and a second optical path are arranged in sequence. A total mirror 4. The first total reflection mirror 4 is perpendicular to the optical path. Outside the output end of the second optical path, a polarization combination plate 7, a second aperture stop 8 and an output mirror 9 are arranged in sequence, and the output ratio of the output mirror 9 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com