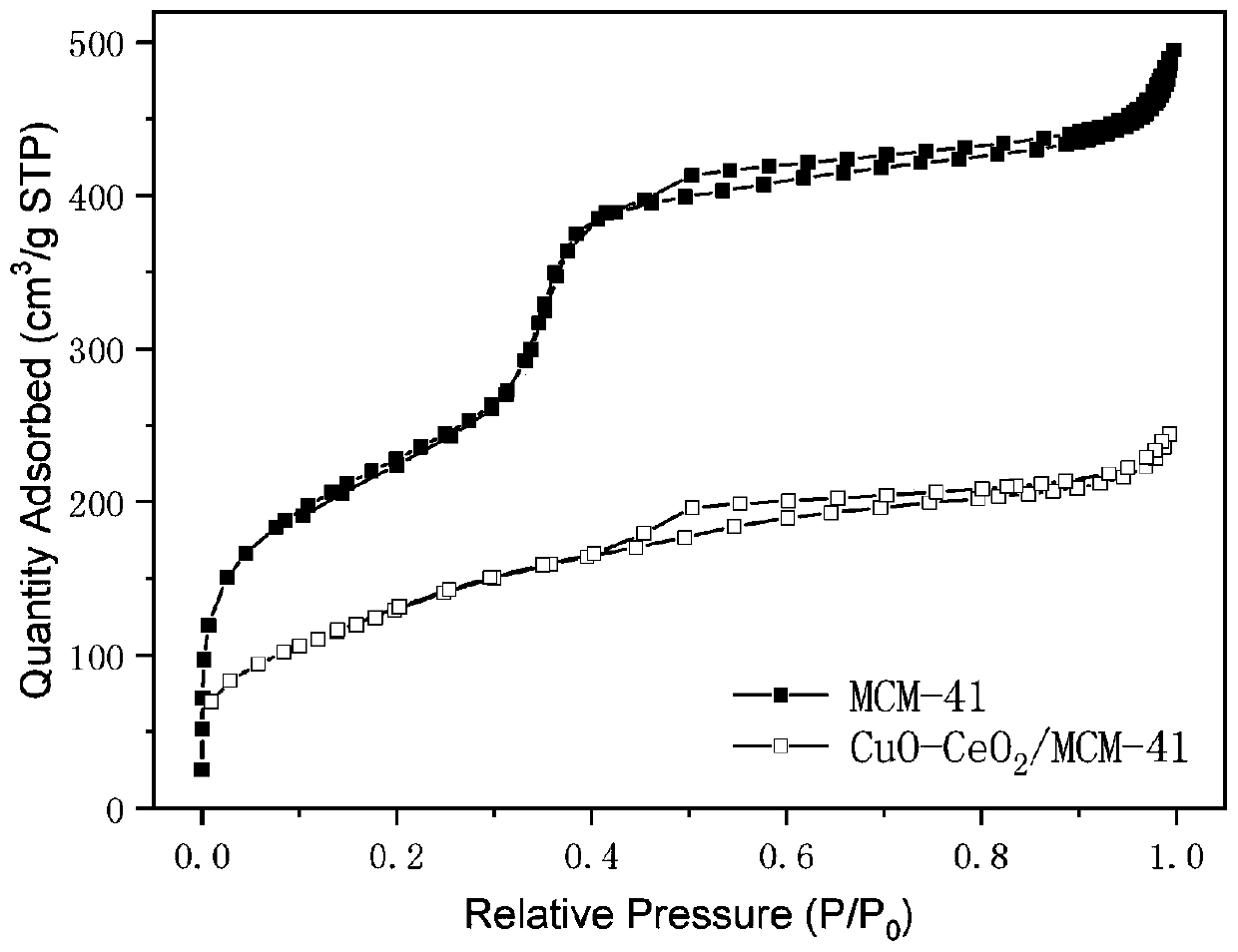

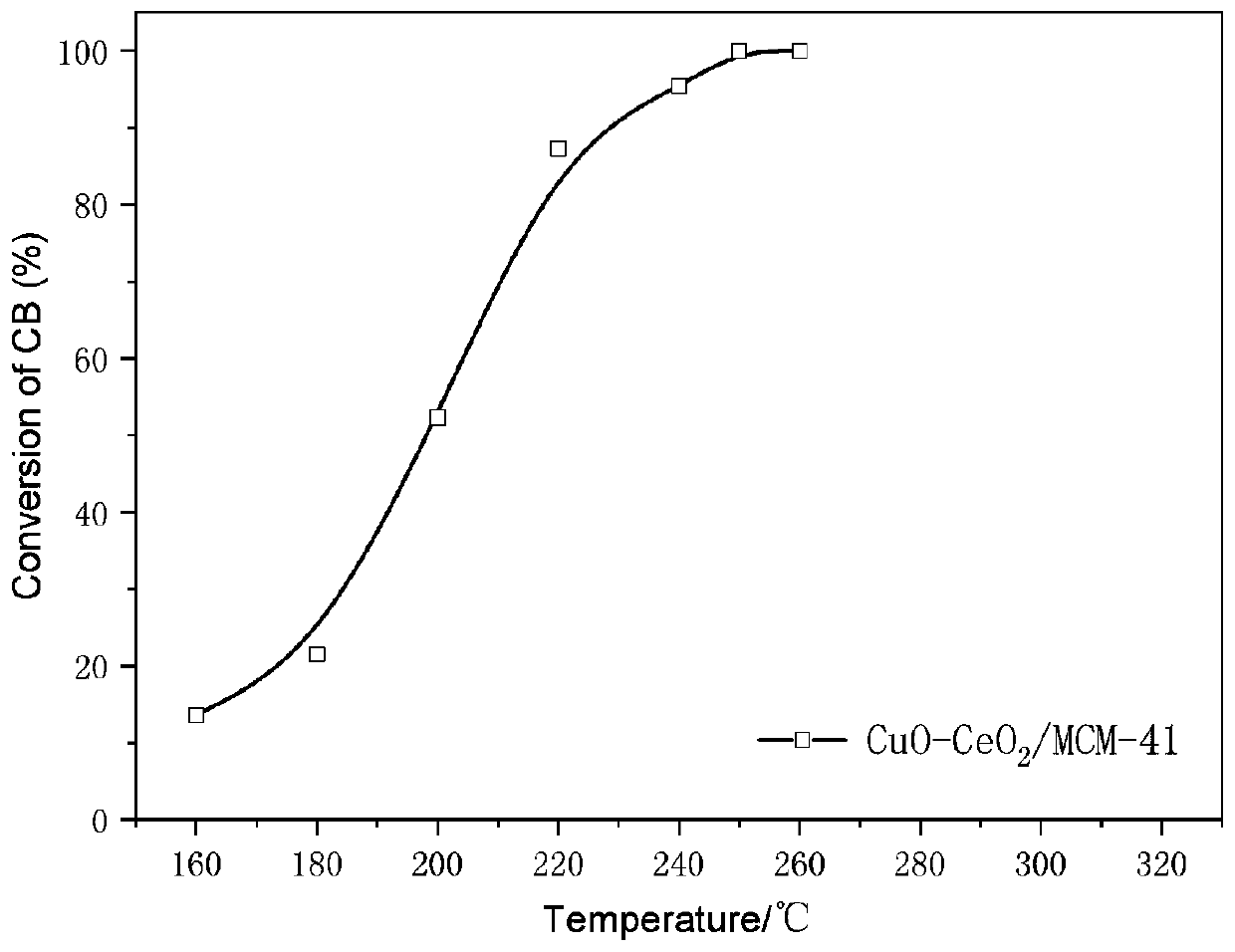

Preparing method and application of MCM-41 supported CuO-CeO2 nanocrystalline catalyst

A technology of MCM-41 and catalyst is applied in the application field of low-concentration chlorobenzene catalytic combustion, which can solve the problems of low activity and achieve the effects of high activity, uniform dispersion and good durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0017] Catalyst preparation

[0018] (1) Preparation of carrier MCM-41: mix 40wt% TEAOH solution and SiO 2 Mix the mixed solution A with a mass ratio of 10:1, stir and mix the obtained mixed solution A with 25wt% CTAC solution and deionized water, and then add SiO 2 A gel was obtained, in which mixed solution A, CTAC solution, deionized water and SiO 2 The mass ratio of the gel is 12.21:20.3:5.94:5.91, then the gel is placed in a Teflon bottle, heated and crystallized at 100°C for 120h, and the solid product obtained after the crystallization is cooled, filtered, and washed is placed at 80°C Dry in an oven for 12 hours, and finally calcinate the dried solid product in air at 550°C for 5 hours to remove the template agent CTAC, and obtain the carrier MCM-41;

[0019] (2)CuO-CeO 2 Preparation of / MCM-41 catalyst: the prepared MCM-41 is dispersed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com