Preparation method of 2-methyl-4-(tetrahydrofuran-2-base) quinoline derivative

A technology of tetrahydrofuran and methylquinoline, which is applied in the field of preparation of 2-methyl-4-quinoline derivatives, can solve the problems of low universality and achieve strong controllability, high reaction yield and wide applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

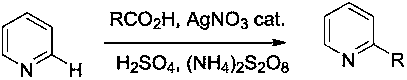

Method used

Image

Examples

Embodiment 1

[0026] 2-Methylquinoline (1 mmol, 143 mg), Selectfluor (4 mmol, 1.4 g) and AgNO 3 (0.2mmol, 34mg) was added to an aqueous solution of tetrahydrofuran (10ml, THF:H 2 O=3:1) and reacted at 50°C for 3h, neutralized with saturated sodium bicarbonate solution, extracted with ethyl acetate (3*10 mL), combined organic layers, washed with saturated brine (20 mL), dried over anhydrous sodium sulfate , filtered and concentrated. Column chromatography (eluent: ethyl acetate / n-hexane = 1:4) yielded 143 mg of the product 2-methyl-4-(tetrahydrofuran-2-yl)quinoline with a yield of 67%.

[0027] 1H NMR (600MHz, CDCl3) δ ppm 8.08 (d, J = 8.4 Hz, 1H), 7.85 (d, J =9.0 Hz, 1H), 7.67 (ddd, J = 8.3, 6.9, 1.3 Hz, 1H), 7.51 – 7.47 (m, 1H), 7.46(s, 1H), 5.58 (t, J = 7.2 Hz, 1H), 4.26 – 4.20 (m, 1H), 4.05 (dd, J = 15.4,7.2 Hz, 1H), 2.76 (s, 3H), 2.62 (dtd, J = 12.5, 7.8, 6.6 Hz, 1H), 2.13 – 2.05(m, 1H), 2.01 (tt, J = 13.8, 7.0 Hz, 1H), 1.84 (ddt, J = 13.1, 8.1, 6.7 Hz, 1H). 13C NMR (151 MHz, CDCl3...

Embodiment 2

[0029] 2-Methyl-6-fluoroquinoline (1 mmol, 161 mg), Selectfluor (4 mmol, 1.4 g) and AgNO 3 (0.2mmol, 34mg) was added to an aqueous solution of tetrahydrofuran (10ml, THF:H 2 O=3:1) and reacted at 50°C for 3h, neutralized with saturated sodium bicarbonate solution, extracted with ethyl acetate (3*10 mL), combined organic layers, washed with saturated brine (20 mL), dried over anhydrous sodium sulfate , filtered and concentrated. Column chromatography (eluent: ethyl acetate / n-hexane = 1:4) yielded 222 mg of the product 2-methyl-6-fluoro-4-(tetrahydrofuran-2-yl)quinoline with a yield of 90%.

[0030] 1 H NMR (600MHz, CDCl 3 ) δ ppm 8.04 (dd, J = 9.2, 5.6 Hz, 1H), 7.58(dd, J = 10.0, 2.7 Hz, 1H), 7.49 (s, 1H), 7.44 (ddd, J = 9.2, 8.1, 2.8 Hz ,1H), 5.20 (dd, J = 9.9, 2.4 Hz, 1H), 4.05 (tdd, J = 14.6, 11.9, 2.6 Hz, 3H),3.92 – 3.86 (m, 1H), 3.80 (ddd, J = 11.8 , 10.2, 4.2 Hz, 1H), 3.48 (dd, J =11.9, 9.9 Hz, 1H), 2.73 (s, 3H).; 13 C NMR (151 MHz, CDCl 3 ) δ ppm 160.92,159.28, 15...

Embodiment 3

[0032] 2-Methyl-6-chloroquinoline (1 mmol, 177 mg), Selectfluor (4 mmol, 1.4 g) and AgNO 3 (0.2mmol, 34mg) was added to an aqueous solution of tetrahydrofuran (10ml, THF:H 2 O=3:1) and reacted at 50°C for 3h, neutralized with saturated sodium bicarbonate solution, extracted with ethyl acetate (3*10 mL), combined organic layers, washed with saturated brine (20 mL), dried over anhydrous sodium sulfate , filtered and concentrated. Column chromatography (eluent: ethyl acetate / n-hexane = 1:4) yielded 210 mg of the product 2-methyl-6-chloro-4-(tetrahydrofuran-2-yl)quinoline with a yield of 80%.

[0033] 1 H NMR (600MHz, CDCl 3 ) δ ppm 7.97 (d, J = 9.0 Hz, 1H), 7.93 (d, J =2.2 Hz, 1H), 7.61 (dd, J = 9.0, 2.3 Hz, 1H), 7.50 (s, 1H), 5.24 ( dd, J = 9.9,2.3 Hz, 1H), 4.13 – 3.99 (m, 3H), 3.94 – 3.87 (m, 1H), 3.80 (ddd, J = 11.8,9.8, 4.5 Hz, 1H), 3.46 (dd, J = 11.9, 9.9 Hz, 1H), 2.73 (s, 3H).; 13 C NMR (151MHz, CDCl 3) δ ppm 159.38, 146.21, 142.77, 131.83, 131.16, 130.05, 124.27, 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com