Preparation method of cross-linked polyacrylic acid large-particle-size bead water absorbent resin

A technology of water-absorbent resin and polyacrylic acid, which is applied in the field of preparation of water-absorbent resin, can solve the problems of low water-absorption rate of water-absorbent resin, lack of bead-shaped particles, uncontrollable size, etc., and achieve easy control of reaction temperature, low production cost, The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

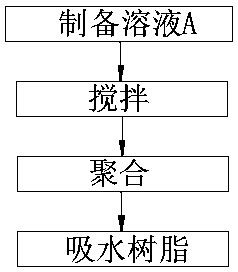

[0022] Example: such as figure 1 Shown, the present invention provides a kind of preparation method of crosslinked polyacrylic acid type large particle size bead-shaped water-absorbing resin, it comprises the following steps:

[0023] 1) Preparation of solution A: After adjusting the temperature to 24°C-29°C of an aqueous solution of acrylic acid and / or its salt with a neutralization degree of 60-80% and a mass concentration of 30-45%, add acrylamide, oxidant and Mixing agent, stir and dissolve until the aqueous solution is clear and transparent, adjust the temperature to 8°C-18°C, and obtain solution A for later use; the amount of acrylamide is 100%-350% of the mass of acrylic acid monomer, and the oxidizing agent is ammonium persulfate or persulfate Potassium sulfate, the consumption is 0.10%-0.29% of the mass of the acrylic acid monomer, and the crosslinking agent is N,N-methylenebisacrylamide, the consumption is 0.04%-0.10% of the mass of the acrylic monomer;

[0024] 2) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com