Polyolefin material with spray-free metal effect and preparation method and application thereof

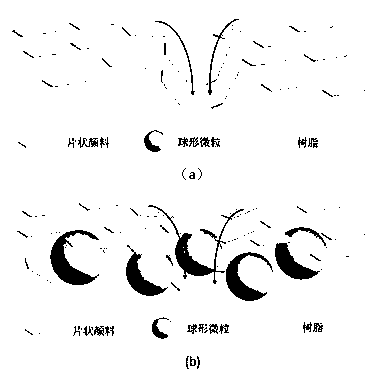

A metal effect and polyolefin technology, applied in the field of plastic coloring, can solve problems such as weld lines and flow marks, and achieve the effect of eliminating weld lines, good dispersion, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

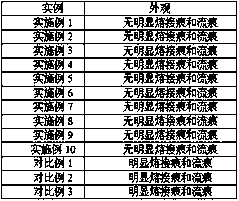

Examples

Embodiment 1

[0059] This embodiment provides a polyolefin material without spraying metal effect, and its preparation method is as follows.

[0060] (1) Preparation of modified glass microspheres

[0061]In parts by weight, weigh 80 parts of glass microspheres (particle size 25-40 microns) and add them to 100 parts of ethanol, then add 20 parts of aminopropyltriethoxysilane, stir and reflux at 90°C for 30 minutes, After cooling to room temperature, filter and dry to obtain modified glass microspheres.

[0062] (2) Preparation of polyolefin material without spraying metal effect

[0063] Put 30 parts of modified glass microspheres, 60 parts of polypropylene (melt index 12g / 10min), 0.5 parts of aluminum powder (particle size 15-25 microns), 0.1 part of antioxidant 1010, and 2 parts of polyethylene wax in a mixer Mix evenly, stirring at a speed of 200 rpm, and stirring for 10 minutes. The homogeneously mixed premixed material is subjected to twin-screw extrusion and granulation at a temper...

Embodiment 2

[0065] This embodiment provides a polyolefin material without spraying metal effect, and its preparation method is as follows.

[0066] (1) Preparation of modified hollow glass microspheres

[0067] In parts by weight, weigh 20 parts of hollow glass microspheres (particle size 25-40 microns) and add them to 100 parts of ethanol, then add 20 parts of aminopropyltriethoxysilane, stir and reflux at 90°C for 30 minutes , cooled to room temperature, filtered and dried to obtain modified hollow glass microspheres.

[0068] (2) Preparation of polyolefin material without spraying metal effect

[0069] Mix 20 parts of modified hollow glass microspheres, 70 parts of polypropylene (melt index 12g / 10min), 0.5 parts of aluminum powder (particle size 15-25 microns), 0.1 part of antioxidant 1010, 2 parts of polyethylene wax, 0.2 parts of blue Color pigments were placed in a mixer and mixed evenly at a stirring speed of 200 rpm for 10 minutes. The homogeneously mixed premixed material is s...

Embodiment 3

[0071] This embodiment provides a polyolefin material without spraying metal effect, and its preparation method is as follows.

[0072] (1) Preparation of modified glass microspheres

[0073] In parts by weight, weigh 80 parts of glass microspheres (particle size 25-40 microns) and add them to 100 parts of ethanol, then add 20 parts of vinyltriethoxysilane, stir and reflux at 90°C for 30 minutes, cool After reaching room temperature, filter and dry to obtain modified glass microspheres.

[0074] (2) Preparation of polyolefin material without spraying metal effect

[0075] Put 30 parts of modified glass microspheres, 60 parts of polypropylene (melt index 12 g / 10min), 0.5 parts of aluminum powder (particle size 15-25 microns), 0.1 part of antioxidant 168, and 2 parts of calcium polystearate in a Mix evenly in a mixer at a stirring speed of 200 rpm for 10 minutes. The homogeneously mixed premixed material is subjected to twin-screw extrusion and granulation at a temperature of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com