One-component polyurea coating for water conservancy and hydropower and preparation method thereof

A single-component, hydropower-water technology, applied in polyurea/polyurethane coatings, coatings, etc., to achieve the effects of ensuring compactness, ensuring yellowing resistance, and improving bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

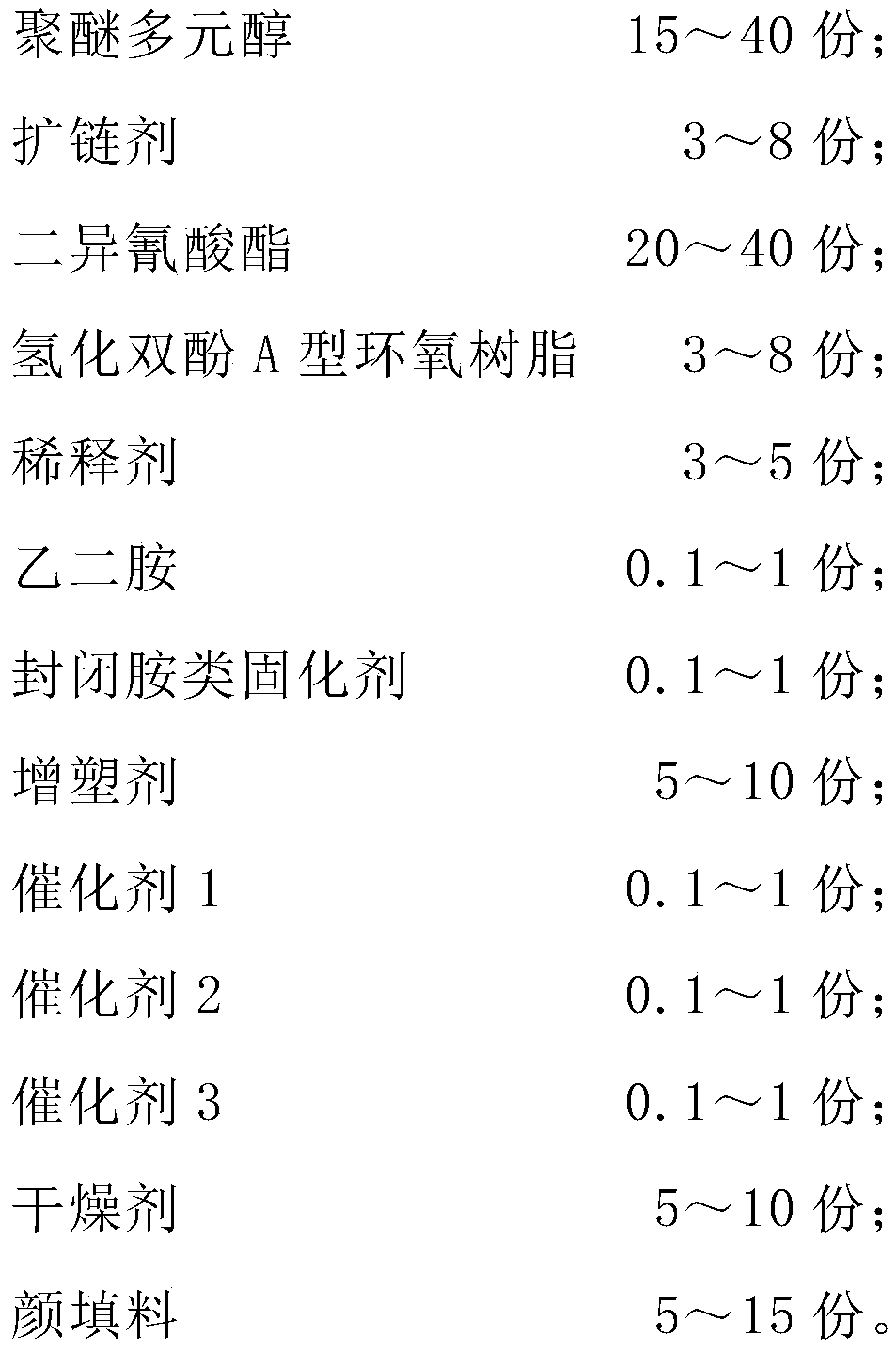

Method used

Image

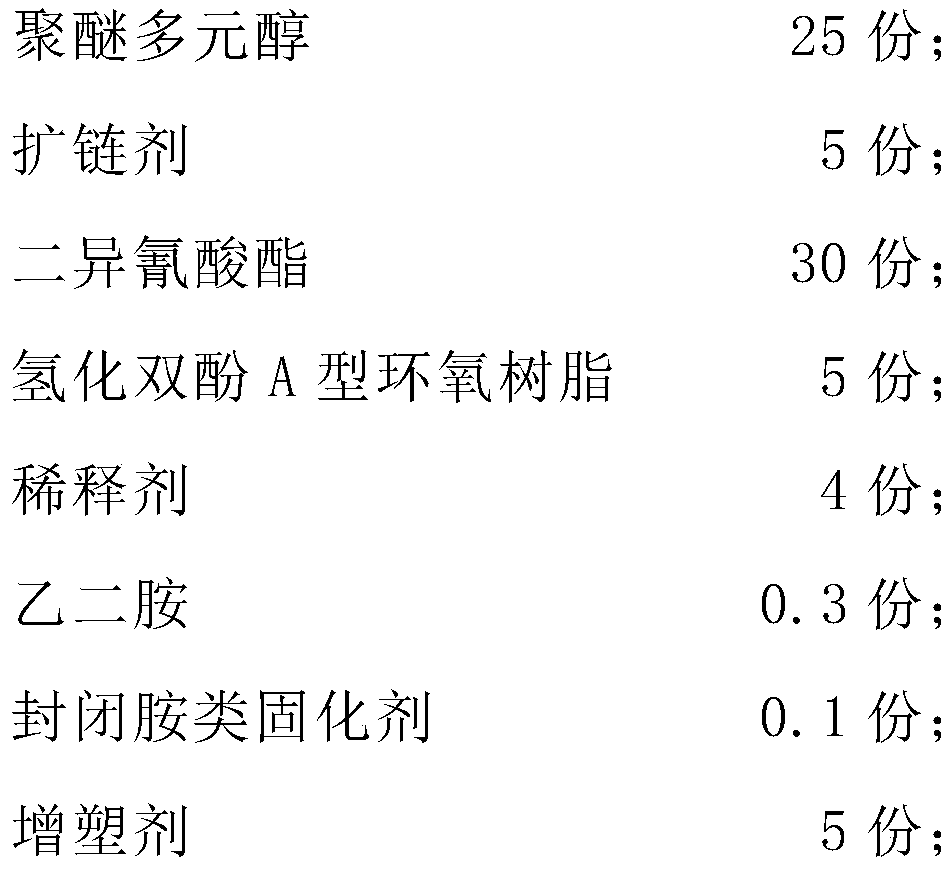

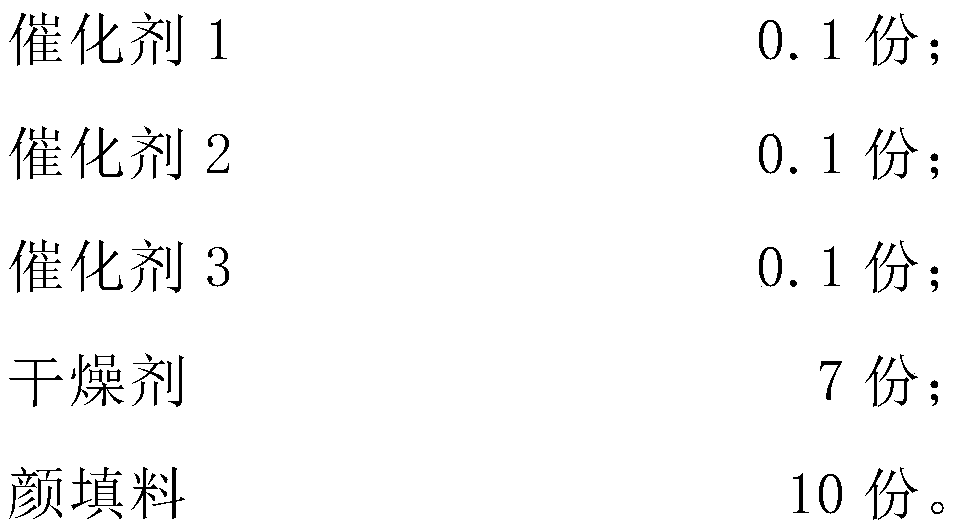

Examples

Embodiment 1

[0059] A kind of preparation method of hydropower water utilization one-component polyurea coating of the present invention, it comprises the following steps:

[0060] A, the preparation of hydrogenated bisphenol A type epoxy resin:

[0061] In a four-neck flask equipped with a thermometer, a reflux condenser, a mechanical stirrer and a dropping funnel, first add hydrogenated bisphenol A solution diluted with methyl isobutyl ketone, catalyst 1 and NaOH in sequence, and stir at 50°C. Then add epichlorohydrin dropwise, and the reaction process is kept at 50°C for reflux reaction for 10 hours. At the same time, the reaction is kept under sealed and anaerobic conditions, and finally hydrogenated bisphenol A epoxy resin is obtained, which is stored for future use;

[0062] B, the preparation of the prepolymer of isocyanate:

[0063] Add diisocyanate, dehydrated polyether polyol, chain extender, and catalyst 2 into a four-neck flask equipped with a thermometer, reflux condenser, me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com