Method for improving self-adhesion performance of natural latex-based adhesive

A technology of natural latex and adhesives, applied in natural rubber adhesives, adhesives, polymer adhesive additives, etc., can solve the problems of pressure-sensitive adhesive products such as initial adhesion and adhesion decline, and achieve improved preparation effect, The effect of improving self-adhesive performance and strong self-adhesive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

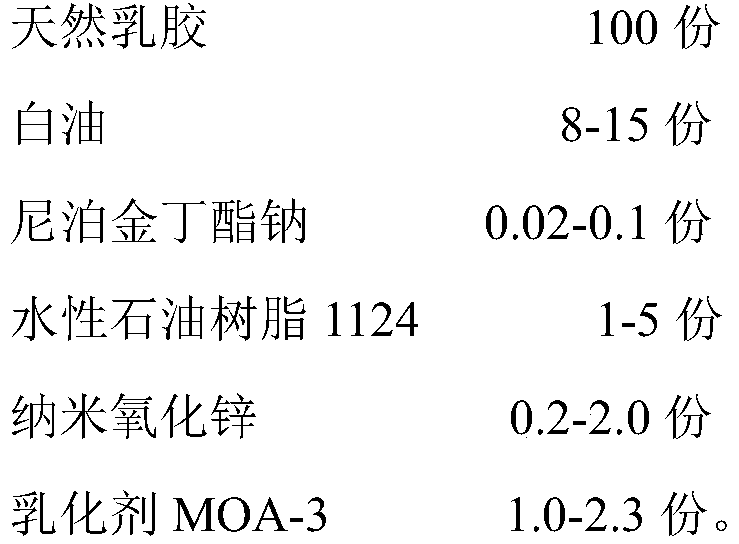

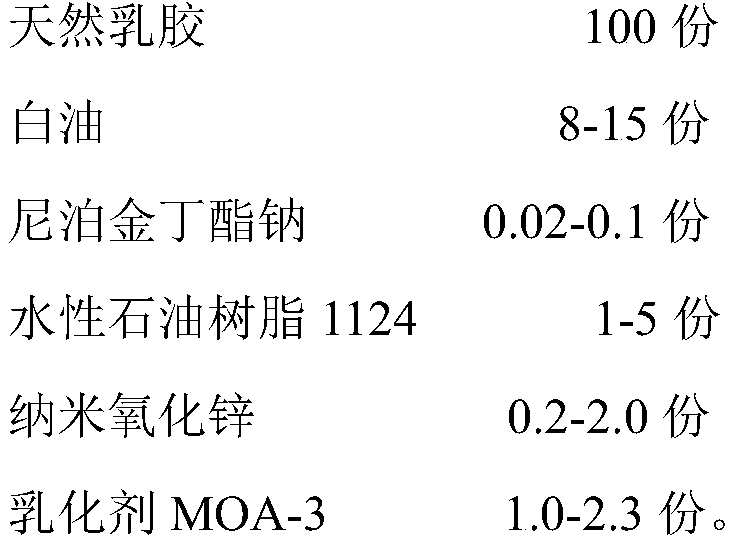

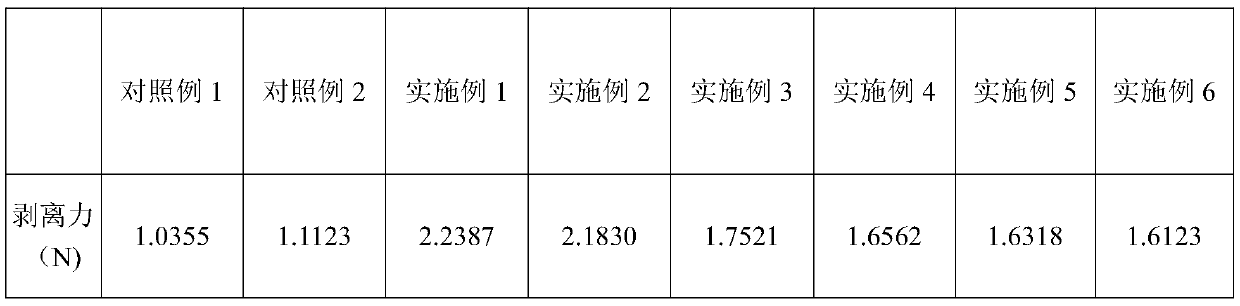

Embodiment 1

[0026] Based on 100 parts by weight of natural latex, add 10 parts of white oil and 1.5 parts of emulsifier MOA-3 to a stirred tank in a water bath at 45°C, and stir for 10 minutes to obtain a clear emulsion; add 0.05 parts of paraben to the clear emulsion Stir the sodium fat for 5 minutes until the powder is evenly dispersed; add the mixed emulsion to 100 parts of natural latex, stir at 45°C for 10 minutes, add 2 parts of water-based resin 1124, stir for 10 minutes, and then add 0.5 parts of nano-zinc oxide dispersed in 20 parts of water , stirred for 10 minutes, and filtered with a 120-mesh filter to obtain a natural latex-based adhesive.

Embodiment 2

[0028] Based on 100 parts by weight of natural latex, add 10 parts of white oil, 1.5 parts of emulsifier MOA-3, and 0.05 parts of sodium butylparaben to a stirred tank in a water bath at 45°C and stir for 15 minutes; add this clear emulsion to 100 parts of natural latex Stir in the latex for 10 minutes, add 2 parts of water-based resin 1124, stir for 15 minutes, then add 1.0 parts of nano-zinc oxide dispersed in 30 parts of water, and stir for 15 minutes; filter through a 120-mesh filter to obtain a natural latex-based adhesive.

Embodiment 3

[0030] Based on 100 parts by weight of natural latex, add 10 parts of white oil, 1.0 part of emulsifier MOA-3, and 0.05 part of sodium butylparaben to a stirred tank in a water bath at 45°C and stir for 10 minutes; add this clear emulsion to 100 parts of natural latex Stir in the latex for 10 minutes, add 2.5 parts of water-based resin 1124, stir for 10 minutes, then add 1.0 parts of nano-zinc oxide dispersed in 30 parts of water, and stir for 10 minutes; filter with a 120-mesh filter to obtain a natural latex-based adhesive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com