Multi-layer structure self-repairing thermal barrier coating layer and preparation method thereof

A multi-layer structure, thermal barrier coating technology, applied in coating, metal material coating process, fusion spraying, etc., can solve problems such as difficult to achieve 100% perfect repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

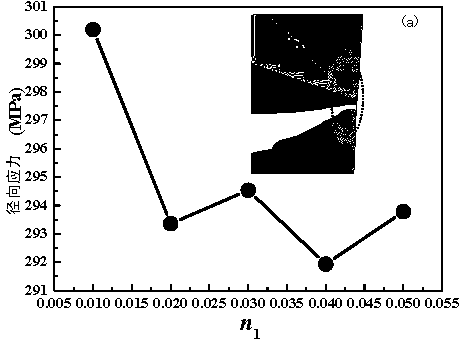

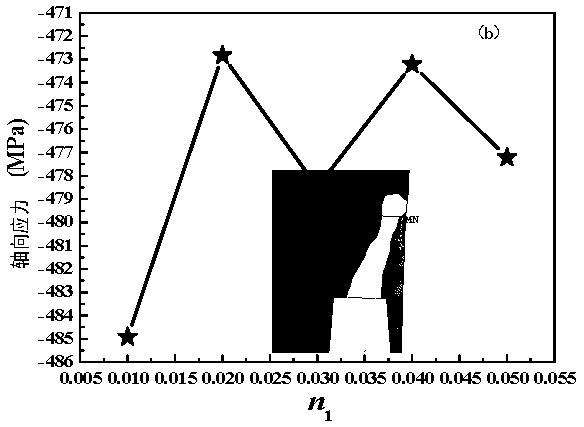

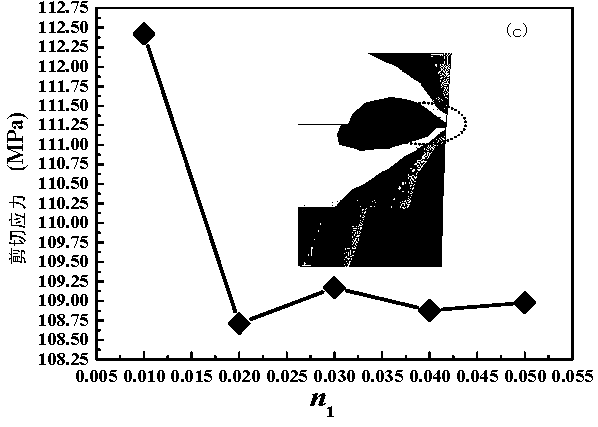

[0033] The invention relates to a self-repairing thermal barrier coating with a multilayer structure and a preparation method thereof, specifically to design and prepare a thermal barrier coating capable of self-repairing at high temperatures, thereby prolonging its service life. The multilayer structure self-healing thermal barrier coating has a three-layer structure, which is YSZ / TAZ((1-y)TiC+xAl 2 o 3 +(y-x)YSZ) / MCrAlY, that is, sequentially deposit MCrAlY primer layer on the superalloy substrate, (1-y)TiC+xAl 2 o 3 +(y-x)YSZ self-healing layer (intermediate layer), YSZ ceramic layer, where M is Co and / or Ni, that is, the underlying layer can be CoNiCrAlY, NiCoCrAlY, CoCrAlY, NiCrAlY, 0.65≤y≤0.85, 0.05≤x≤0.15 , x, y all represent weight percent (wt.%), namely 65wt.%≤y≤85wt.%, 5wt.%≤x≤15wt.%. The present inventor adopts finite element simulation calculation to design and optimize the multilayer structure YSZ / TAZ ((1-y)TiC+xAl 2 o 3+(y-x)YSZ) / MCrAlY self-healing thermal ...

Embodiment 1

[0059] Preparation of spray feed. The preparation process is as follows: first ball milling → first spray drying → first sintering → second ball milling → second spray drying;

[0060] One-time ball milling: feed 25kg, water content 60.2%, add 4% PVA aqueous solution, ball mill 400r / min, 6h, ball mill pulping is the original nano-scale TiC, Al 2 o 3 , YSZ is mixed according to the stoichiometric ratio, and a certain amount of deionized water and binder (usually polyvinyl alcohol PVA) and a certain amount of ball milling balls are added. The ZrO used in this embodiment 2 The diameter of the ball is Φ7mm, and the ratio of the added ball to material is operated according to the volume ratio of 10:3;

[0061] Primary spray drying: the rotation speed of the atomizing disc is 23000r / min, the inlet air temperature is 230°C, the outlet air temperature is 110°C, the feeding frequency is 4-6kHz, and the particle size analysis of the primary spray drying powder is carried out. The par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com