Preparation method of metal core-shell nanowire

A core-shell nano and metal technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of large demand for experimental equipment, affecting material performance, and difficult control of conditions, etc., to achieve operability Strong, simple and convenient, and the effect of promoting development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

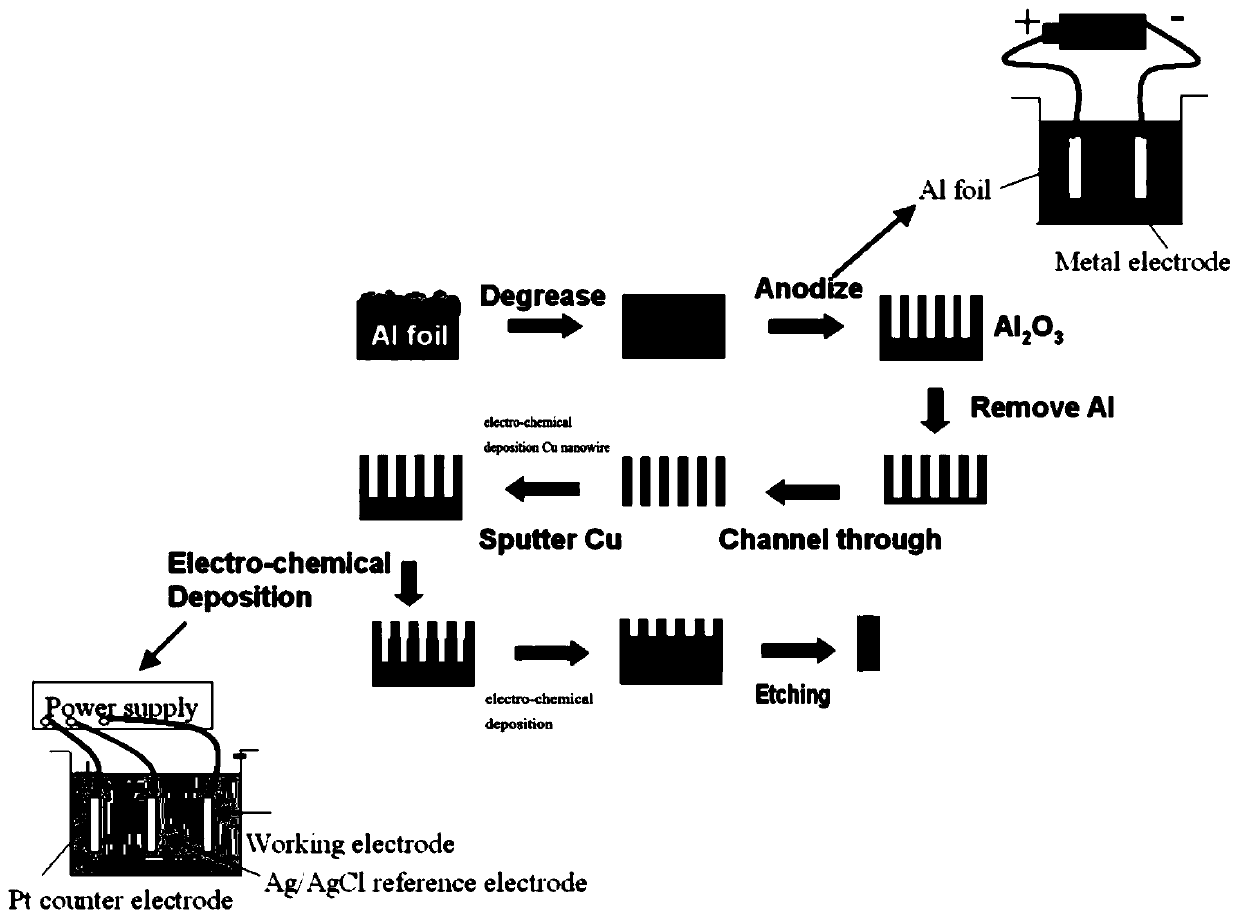

[0045] A preparation method for preparing metal core-shell nanowires, comprising the following steps:

[0046] (a) Template preparation

[0047] Aluminum sheet annealing and ultrasonic cleaning pretreatment: anneal the aluminum sheet (thickness 50-60 μm) at 450-550°C for 2-4 hours, then ultrasonicate in acetone for 5-15 minutes, and then soak in alkaline solution for 5-10 minutes. Finally, ultrasonication in acetone for 3 to 5 minutes completes the pretreatment.

[0048] (a-1) Primary oxidation: place the aluminum sheet pretreated by annealing and ultrasonic cleaning in 0.3-0.5mol / L oxalic acid aqueous solution, and electrochemically corrode it for 4-6 hours at a voltage of 40-60V and a temperature of 0-3°C , to obtain primary alumina flakes;

[0049] (a-2) Removal of the primary oxide film: Take the primary alumina sheet, soak it in a mixed aqueous solution of phosphoric acid and chromic acid at 50-70°C for 12-16 hours, and then clean it with deionized water to obtain the a...

Embodiment 1

[0065] Potentiostatic Preparation of Co-Ni Core-Shell Nanowires

[0066] 1) Template preparation:

[0067] (1-1) Primary oxidation: Place the aluminum sheet pretreated by annealing and ultrasonic cleaning in 0.4mol / L oxalic acid aqueous solution, and electrochemically corrode for 5 hours at a voltage of 50V and a temperature of 1°C to obtain a primary aluminum oxide sheet.

[0068] (1-2) Removing the primary oxide film: take the primary alumina sheet, soak it in a mixed aqueous solution of phosphoric acid and chromic acid at 60°C for 14 hours, and then clean it with deionized water to obtain the aluminum sheet from which the primary oxide film has been removed.

[0069] In the mixed aqueous solution of phosphoric acid and chromic acid, the concentration of phosphoric acid is 4.5wt%, and the concentration of chromic acid is 1.5wt%.

[0070] (1-3) Secondary oxidation: Place the aluminum sheet from which the primary oxide film has been removed in 0.4mol / L oxalic acid aqueous sol...

Embodiment 2

[0079] Pulse electrodeposition prepares the method for Co-Ni core-shell nanowire (step (2) adopts pulse electrodeposition), comprises the steps:

[0080] (1) Template preparation:

[0081] (1-1) Primary oxidation: Place the aluminum sheet pretreated by annealing and ultrasonic cleaning in 0.3mol / L oxalic acid aqueous solution, and electrochemically corrode for 6 hours at a voltage of 40V and a temperature of 0°C to obtain a primary aluminum oxide sheet.

[0082] (1-2) Removing the primary oxide film: take the primary alumina sheet, soak it in a mixed aqueous solution of phosphoric acid and chromic acid at 50°C for 16 hours, and then clean it with deionized water to obtain the aluminum sheet from which the primary oxide film has been removed.

[0083] In the mixed aqueous solution of phosphoric acid and chromic acid, the concentration of phosphoric acid is 3wt%, and the concentration of chromic acid is 2wt%.

[0084] (1-3) Secondary oxidation: Place the aluminum sheet from whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com