The invention discloses a replacement type rotary jet grouting stratum reinforcing method

A technology of grouting and formation, applied in underground chambers, earth drilling, soil protection, etc., can solve the problems of poor quality reinforcement, large waste discharge, long construction period, etc., and achieve high operating efficiency and automation High-level, high-tech effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

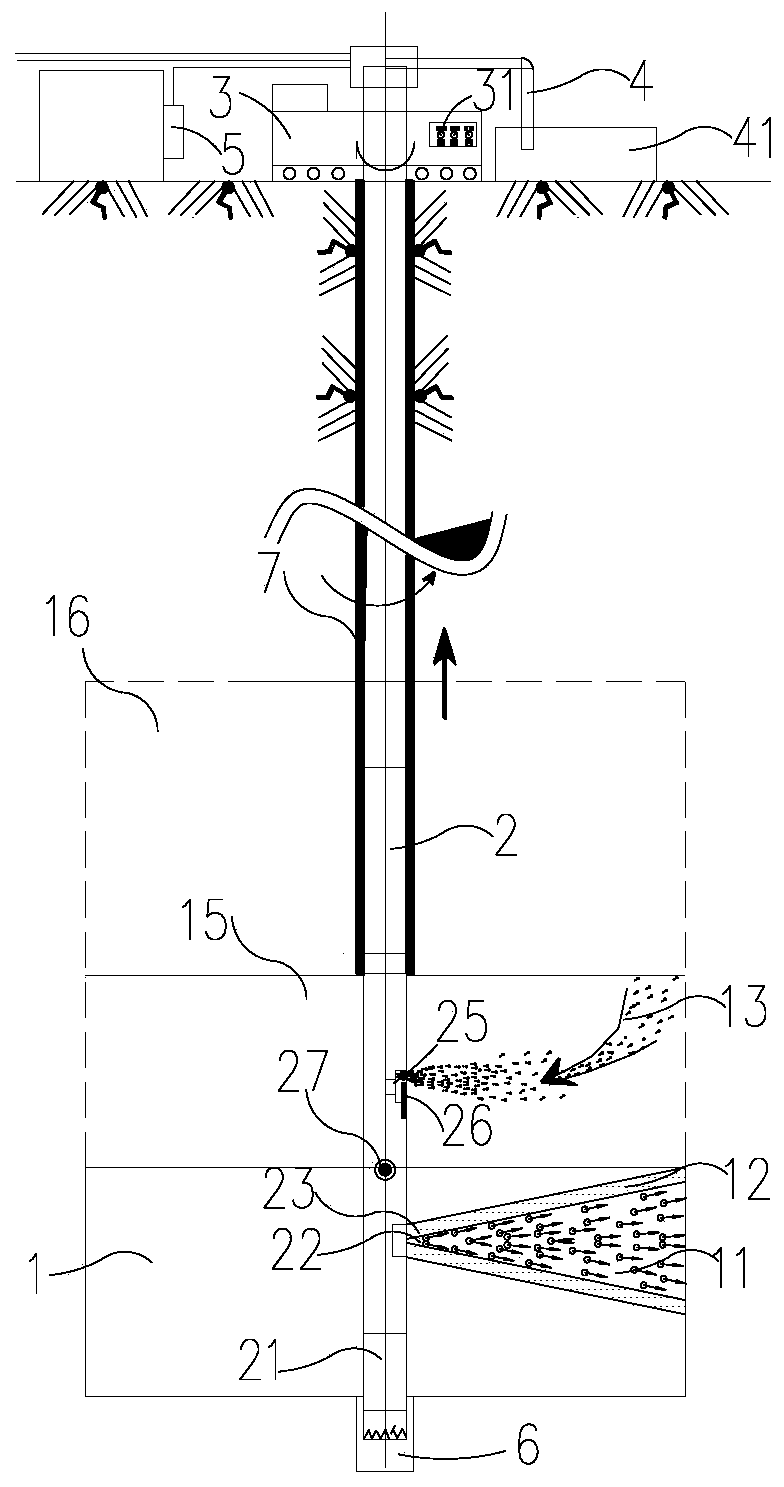

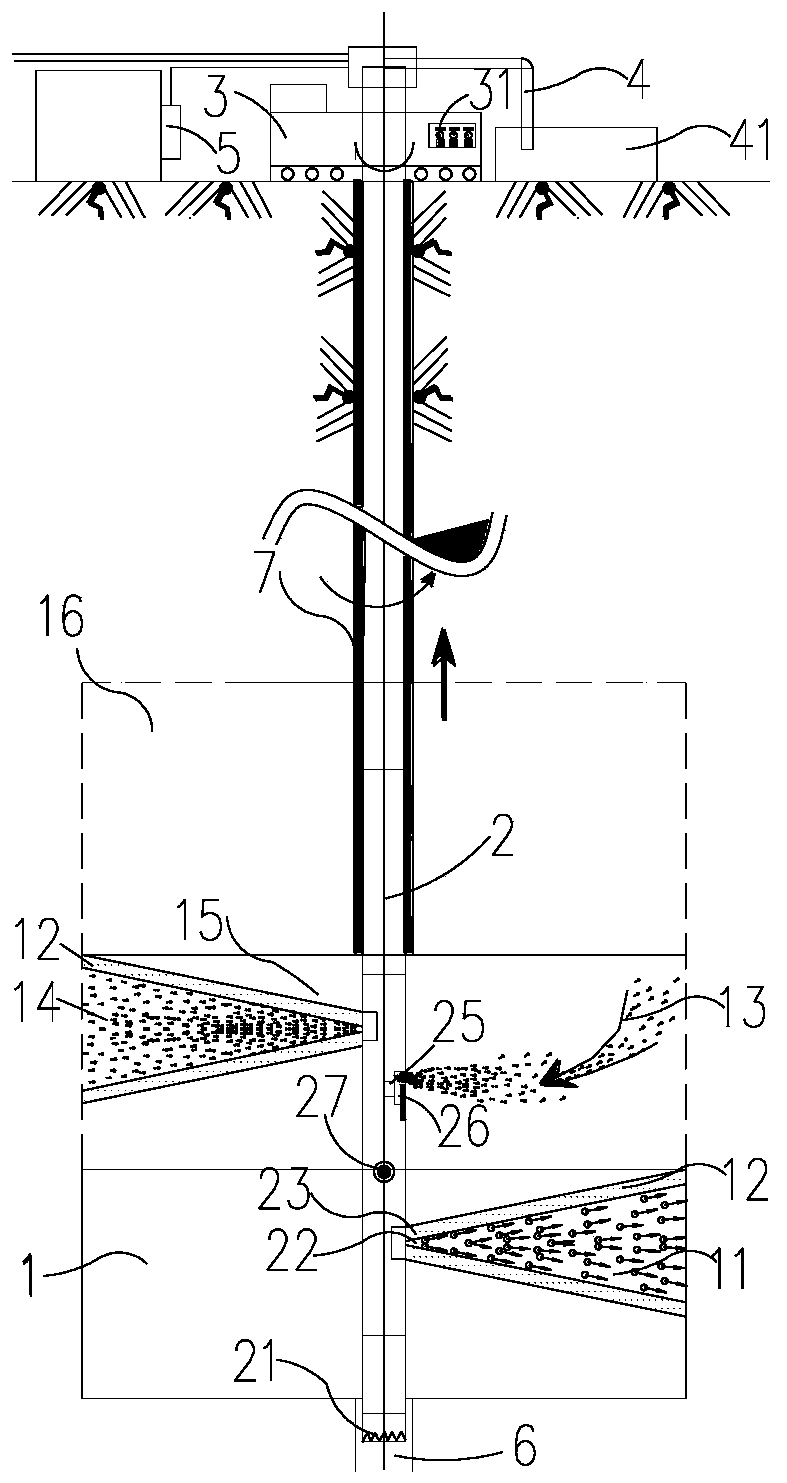

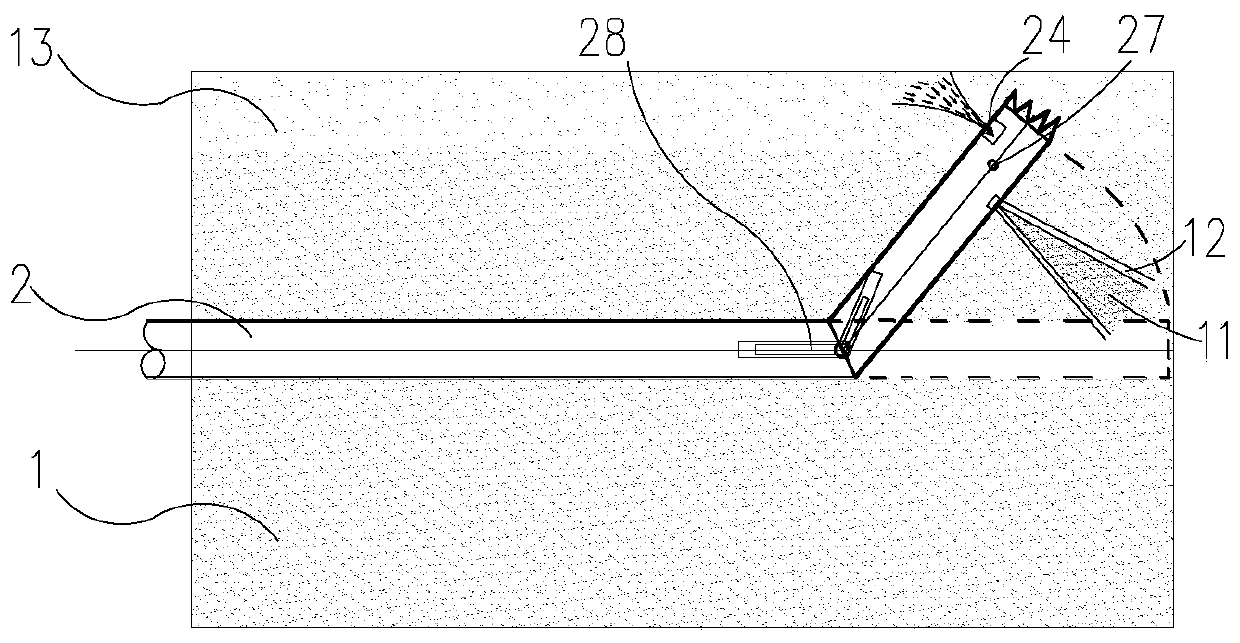

[0037] Such as figure 1 As shown, in order to form the jet-jet reinforced body 1 in the pre-reinforced area 16, a jet-jet drill bit 21 is first installed at the bottom of the jet-jet drill pipe 2, and the jet-jet drill 3 is used to drive the pilot hole to reach the bottom of the reinforced area.

[0038] Distributed on the rotary grouting drill bit 21 are: reinforcement slurry nozzle 22 , high-pressure air flow nozzle 23 , suction mud discharge port 25 , hydraulic control valve 26 and pressure monitoring sensor 27 .

[0039]When the jetting drill bit reaches the bottom of the pre-reinforced area 16, turn on the high-pressure generating device such as the high-pressure pump, and the curing agent slurry is delivered to the slurry nozzle 22 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com