Preparation method of capillary tube SERS substrate and SERS capillary tube

A capillary and substrate technology, applied in the field of SERS capillary, can solve the problems of cumbersome, non-uniform excitation light focusing, and reduce the detection effect of SERS, and achieve the effect of uniform signal collection, high excitation efficiency, and effective focusing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

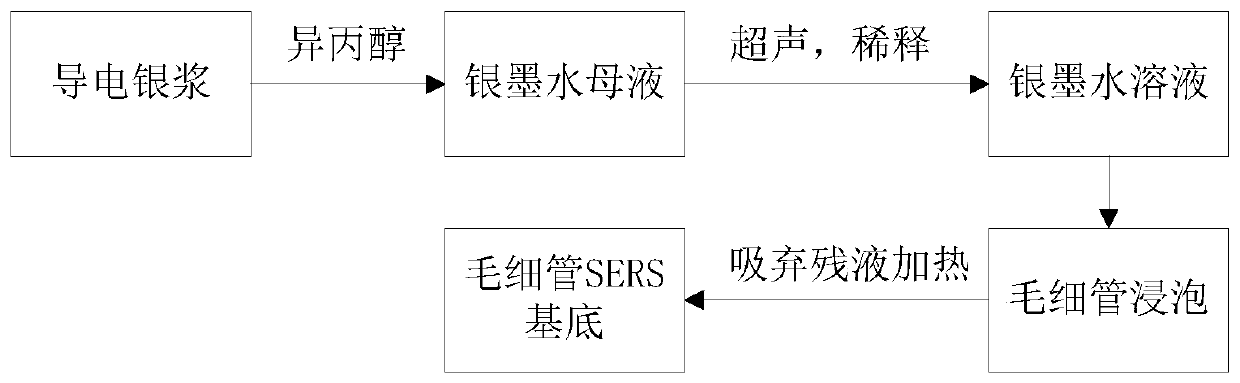

[0029] see figure 1 , the preparation method of capillary SERS substrate, comprises the steps:

[0030] (1) Preparation of metal nanoparticle ink mother liquor: add 1mL of isopropanol solution with a mass fraction of 70% to the metal nanoparticle conductive slurry, and ultrasonically 15min under darkroom conditions to obtain metal nanoparticle ink mother liquor; wherein, metal nanoparticle The volume ratio of particle conductive slurry to isopropanol is 1:1; the mother liquid of metal nanoparticle ink is preferably silver.

[0031] (2) Preparation of nanoparticle precursor ink: Dilute silver metal nanoparticle ink mother liquor with 70% isopropanol solution to obtain nanoparticle precursor ink; wherein, the volume ratio of metal nanoparticle conductive slurry to isopropanol is 1: 1.

[0032] (3) Nanoparticle attachment: Soak the polygonal capillary in the nanoparticle precursor ink, and keep soaking for 5 minutes, absorb the remaining nanoparticle precursor ink in the polygo...

Embodiment 2

[0034] This part differs from Example 1 in that:

[0035] (2) Dilute the silver ink mother solution with 70% isopropanol solution to obtain a silver ink solution, wherein the volume ratio of metal nanoparticle conductive slurry to isopropanol is 1:32.

[0036] (3) Use the capillary effect to soak the rectangular capillary in silver ink for 30 minutes, absorb the remaining silver ink in the polygonal capillary, quickly place the capillary on a preheated heating platform at 135°C, and heat for 10 minutes.

Embodiment 3

[0038] This part differs from Example 1 in that:

[0039] (2) Dilute the silver ink mother solution with 70% isopropanol solution to obtain a silver ink solution, wherein the volume ratio of metal nanoparticle conductive paste to isopropanol is 1:15.

[0040] (3) Use the capillary effect to soak the hexagonal capillary in silver ink for 16 minutes, absorb the remaining silver ink in the polygonal capillary, quickly place the capillary on a preheated 135°C heating platform, and heat for 7 minutes.

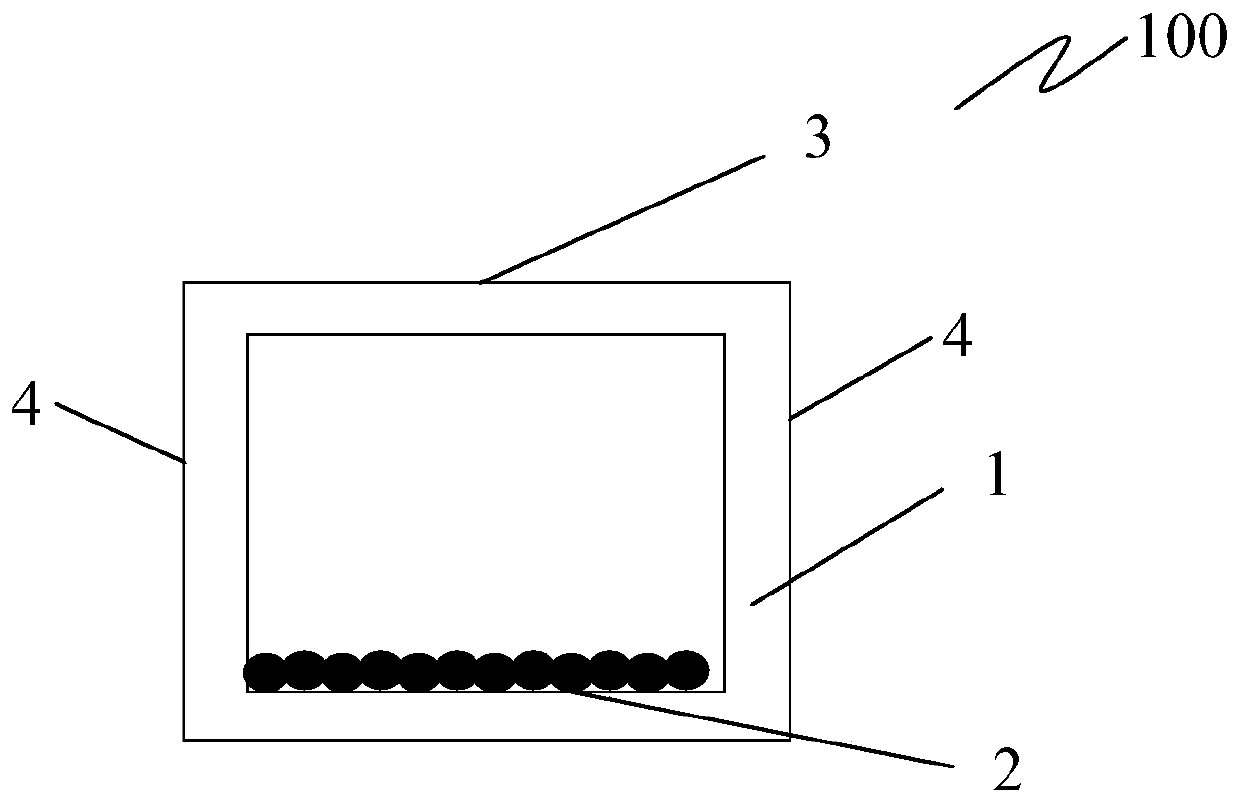

[0041] The cross-sectional view of the prepared SERS capillary 100 is as follows figure 2 As shown, the SEM image of the inner wall of the SERS capillary 100 is as follows image 3 shown. By measuring the concentration of 10 -4 M's rhodamine 6G solution, to evaluate the reproducibility of the measurement results of the SERS capillary 100 prepared in different batches using the spectral peak 1510cm -1 Intensity calculation relative standard deviation, the result is 15%, showing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com