High-efficiency mobile phone lens assembly process

A lens assembly, high-efficiency technology, applied in installation, optics, instruments, etc., can solve the problems of reducing the market competitiveness of product yield, difficult to ensure the consistency of assembly quality, and low surface hardness of mobile phone lenses, so as to avoid the pattern being damaged. Scratch, antibacterial effect is lasting and efficient, the effect of improving scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A high-efficiency mobile phone lens assembly process, the method includes the following steps:

[0038] 1) Forming: Put the formed and sheared lenses into 12*12 collars, and put 144 lenses into each collar;

[0039] 2) Coating: the whole plate (12*12) is loaded into the jig for coating;

[0040] 3) Assembly: Assemble the whole plate, 144 pieces at one time;

[0041] Complete the high-efficiency mobile phone lens assembly process.

[0042] Preferably, the installation equipment used in the process is an automatic multi-head assembly machine: the manufacturer is: Shenzhen Xindingyuan Photoelectric Co., Ltd., model: XDY-ZL-D2

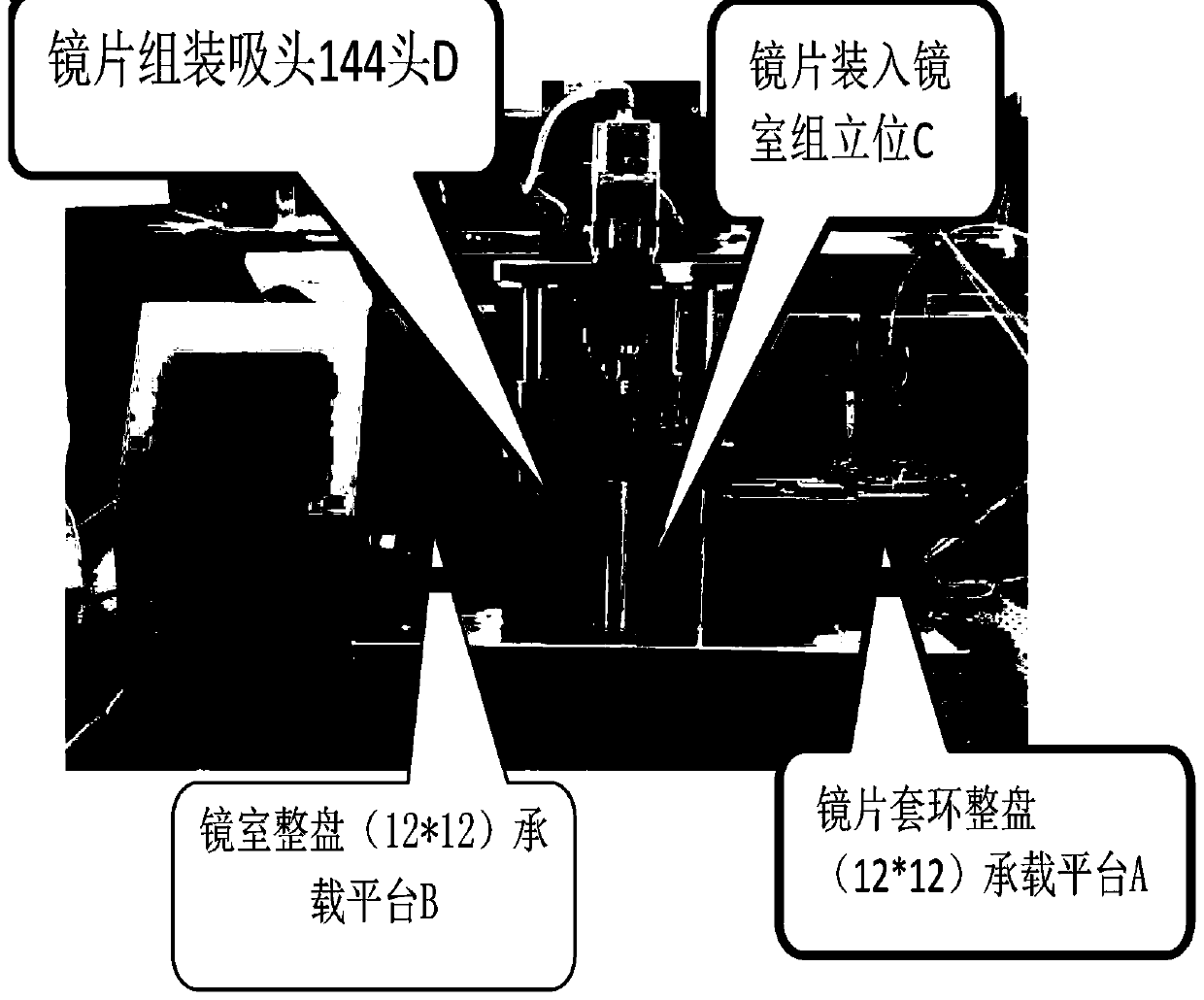

[0043] Further preferably, as Figure 1-2 As shown, the step 3) assembly of the whole plate includes the following steps:

[0044] 1. After disassembling the lens collar, place the lens collar 12*12 flat on the lens carrier A;

[0045] 2. Place the lens guide disc flat on the mirror chamber that has been placed, and the guide disc hole should b...

Embodiment 2

[0050] The lens used in the process described in Example 1 consists of a polycarbonate layer, a pattern layer, an ultraviolet glue layer, a polyethylene terephthalate layer, and a bacteriostatic layer that are sequentially stacked from bottom to top.

[0051] Preferably, the thickness of the ultraviolet glue layer is 6 μm, the solid content of the ultraviolet glue is 85%, and the viscosity is 1500cps;

[0052] The hardness of the polyethylene terephthalate layer is not lower than 3H, its thickness is 0.18mm, and the thickness of the polycarbonate layer is 0.5mm.

[0053] The raw materials of the antibacterial layer include the following components in parts by weight: 25 parts of ethanol, 24 parts of n-butyl acrylate, 28 parts of nano-copper, 23 parts of copper sulfate, 15 parts of silica gel, 9 parts of fluorinated polyethylene, 12 parts of titanium dioxide, 3 parts of chitosan.

[0054] The manufacturing process of the lens is:

[0055] A The polycarbonate layer material is...

Embodiment 3

[0062] Other embodiment 2, the raw material of the antibacterial layer also includes the following components by weight: 2 parts of konjac glucan. The performance of the lens of the mobile phone in this embodiment is tested, and the antibacterial time of the lens is as long as 10 hours, the viscosity is first grade, and the wear rate of the lens body is 7% after grinding at 20000rpm for 5 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com