Bipolar battery composite current collector structure and preparation method

A bipolar battery and current collector technology, applied in the field of electrochemical energy storage, to achieve the effect of increasing the payload, expanding the range of the process window, and increasing the cruising range or standby time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

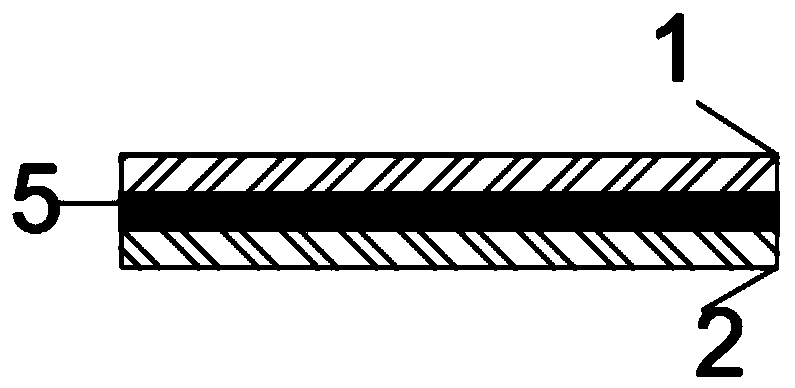

[0049] Example 1: Preparation and use of carbon-(copper-aluminum)-carbon bipolar current collector

[0050] 1. Determine the surface roughness of the copper and aluminum foil that needs to be processed. Determine the thickness of the protective layer according to the roughness. In this example, a copper-aluminum conductive substrate (5) with a roughness of 400 nm is selected. 2 μm thick carbon protective layers (1) and (2) are respectively deposited on both sides of the copper-aluminum conductive substrate (5).

[0051] 2. Put the selected copper and aluminum foil roll into the winding vacuum chamber.

[0052] 3. Vacuum the sputtering chamber to 10 -6 mbar. Adjust the Ar gas flow rate of the etching target process to a process pressure of 10 -3 mbar, adjust the etching power to 2130kw, and the Ar gas flow at the carbon target position until the process pressure is 10 -3 mbar, sputtering power 1780kw.

[0053] 4. Turn on the heater in the process area to heat the copper ...

example 2

[0061] Example 2: Preparation and use of carbon-aluminum bipolar current collector

[0062] The carbon protective layer deposition process in this example is consistent with the carbon-(copper-aluminum)-carbon bipolar current collector carbon protective layer deposition process.

[0063] 1. Deposit the carbon protective layer (1) on the smooth side of the aluminum conductive substrate (11) using a carbon-(copper-aluminum)-carbon bipolar current collector carbon protective layer deposition process. After deposition, the structure is as Figure 7 shown.

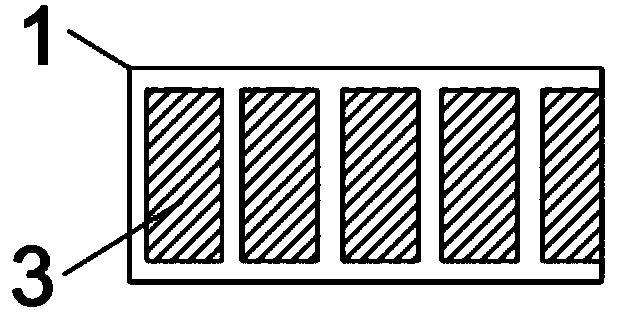

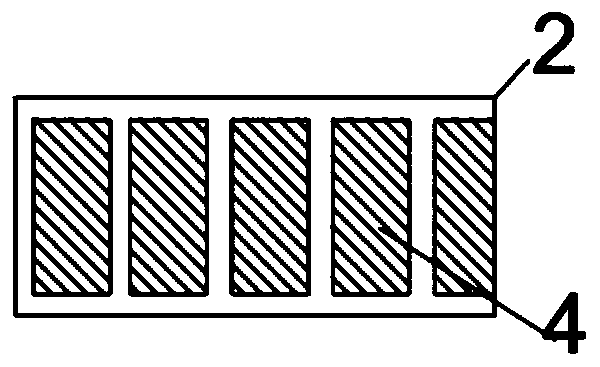

[0064] 2. According to the process requirements, the negative electrode material (3) is coated on the side of the carbon protective layer (1), and the positive electrode material (4) is coated on the side of the aluminum wool surface. Coating shape and structure such as Figure 8 and 9 shown.

[0065] 3. After the coating is completed, follow the Figure 10 The cutout shown is a bipolar electrode sheet, where (12) is the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com