Method and apparatus for quantitatively analyzing gaseous process stream

A material flow, gaseous technology, applied in the field of quantitative analysis of gaseous process material flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

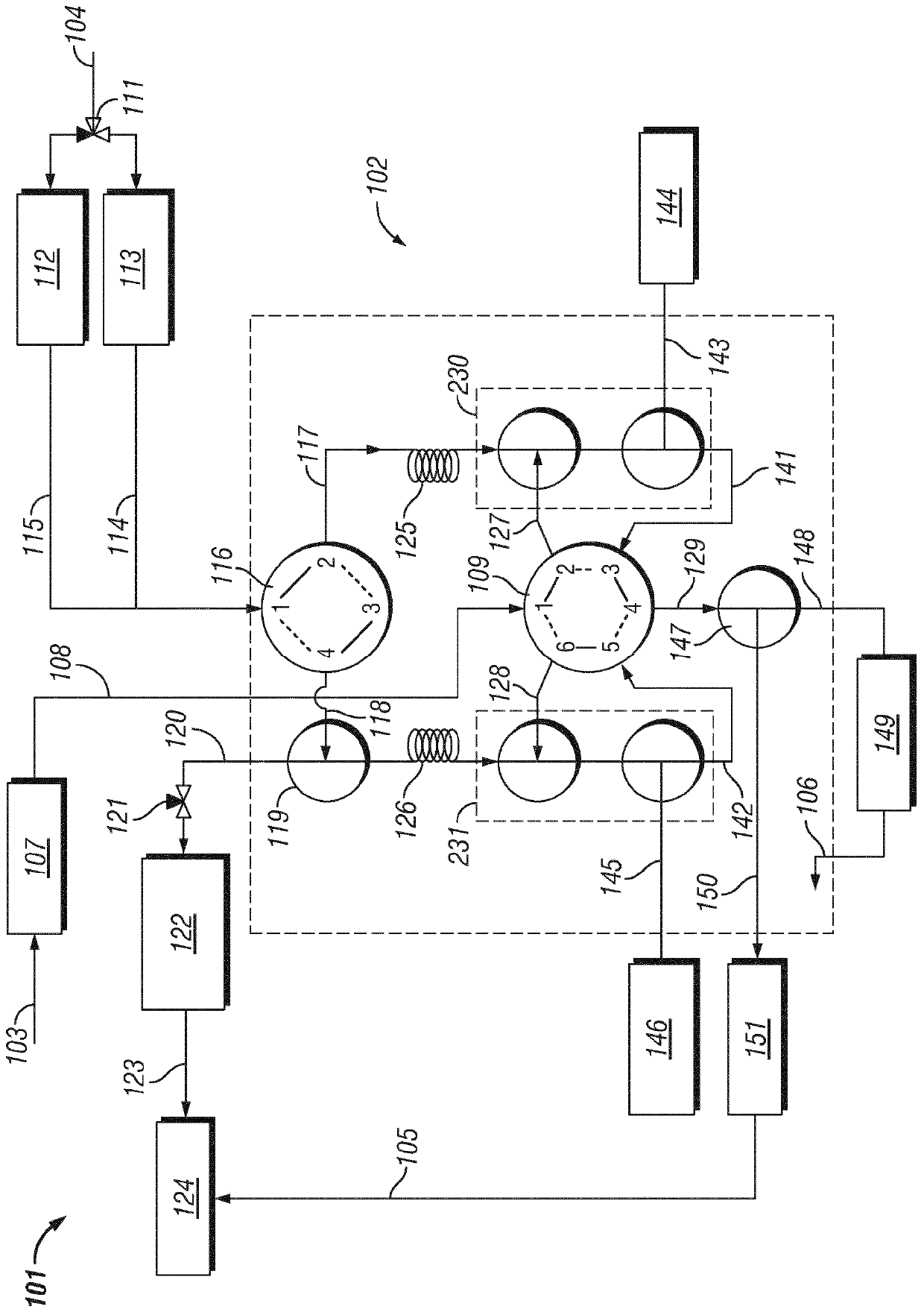

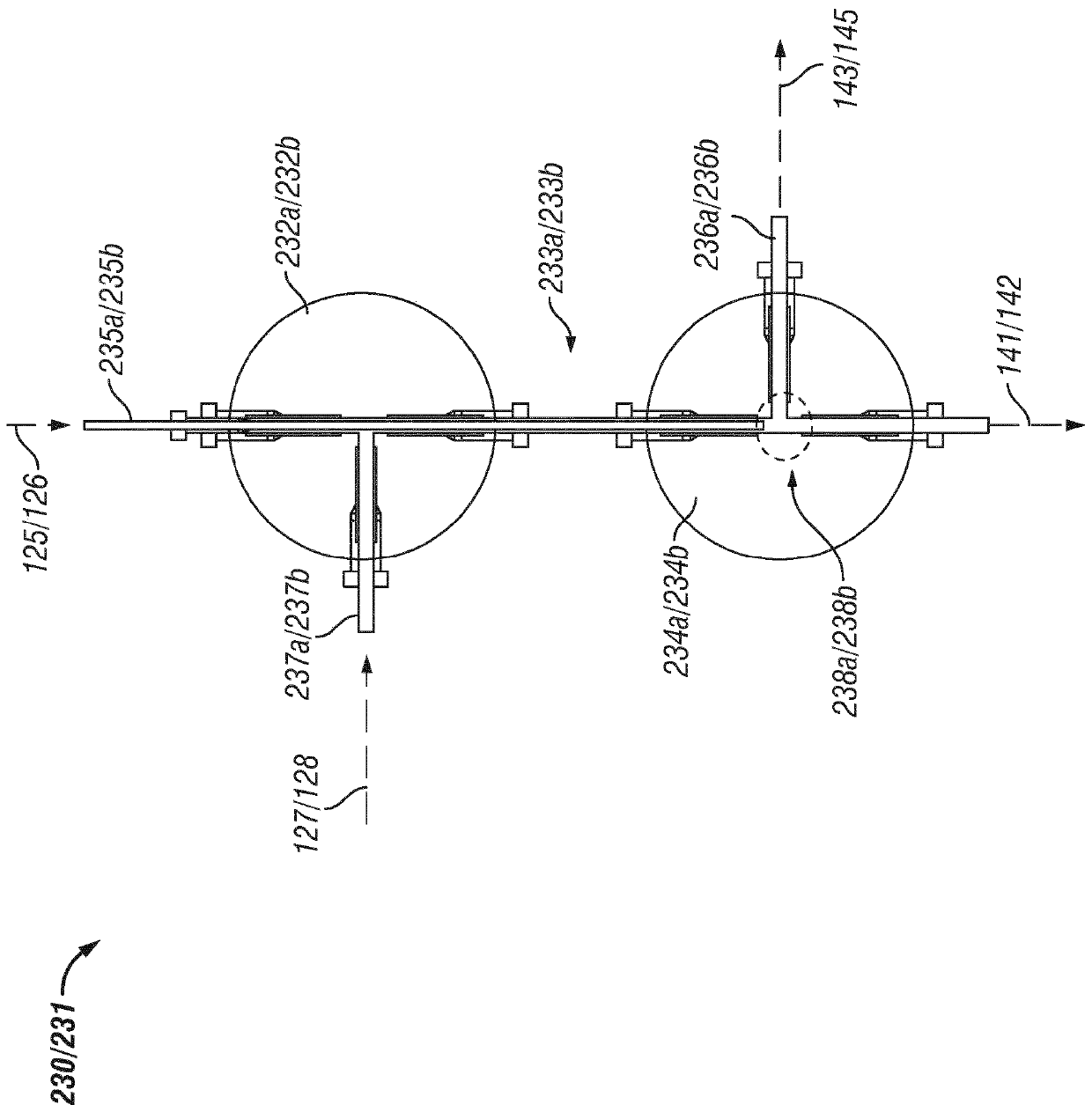

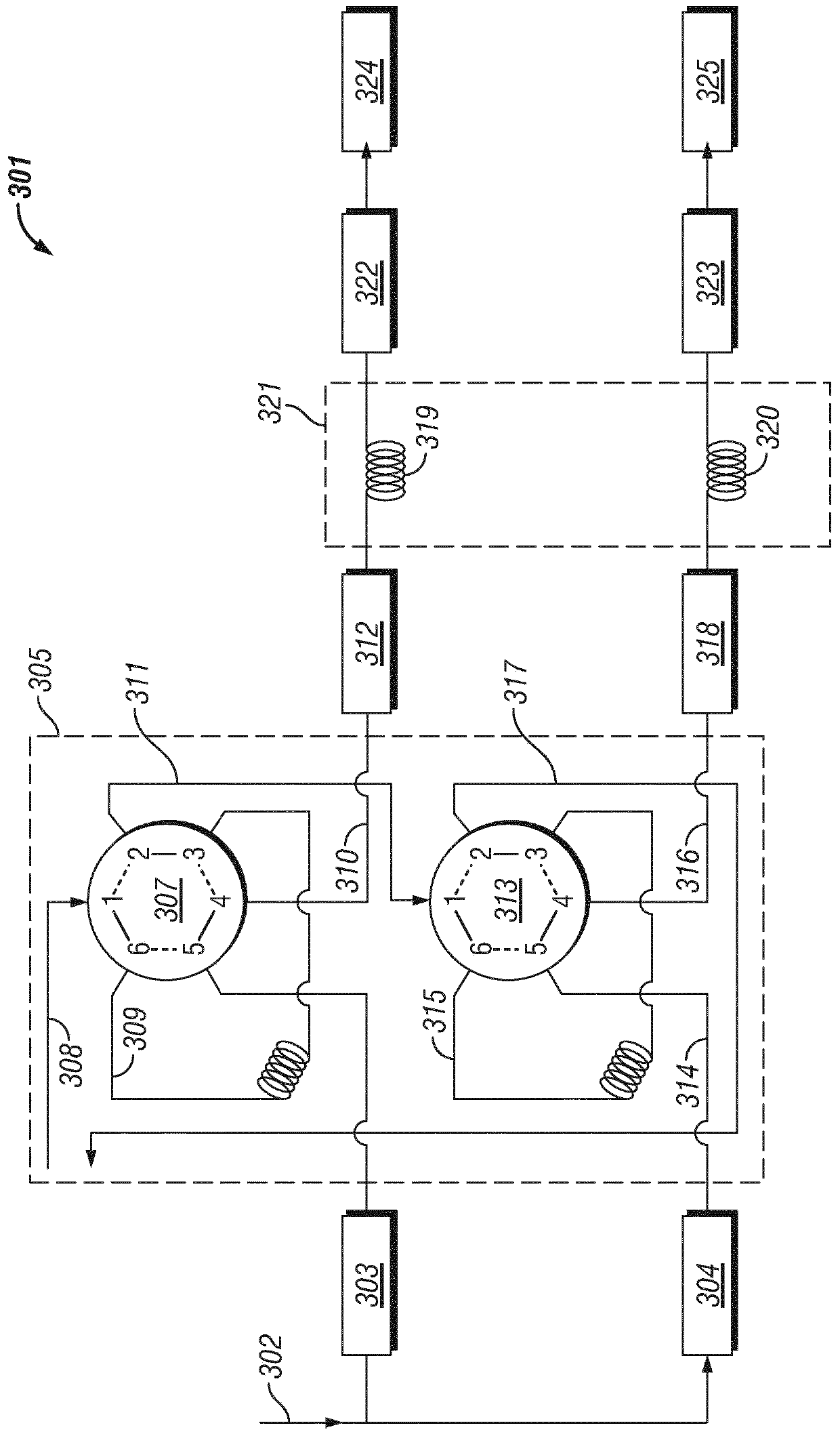

Method used

Image

Examples

Embodiment

[0174] Table 1 shows the sequence of operating steps to be performed on the gas blending system in order to start with known concentrations of methyl iodide (MI), ethyl iodide (EI), vinyl iodide (VI), methyl chloride (MC), Halide Standard Gases for Ethyl Chloride (EC) and Vinyl Chloride (VC), using nitrogen as the diluent gas to prepare diluted calibration standards with the desired nominal concentration (with 50 ppbv ethyl iodide as the target concentration).

[0175] Table 1. Sequence of operations for preparing calibration gas samples

[0176]

[0177]

[0178]

[0179] The sequence of operations given in Table 1 was used to generate a series of calibration gases used to provide full range calibration of the GC equipment. Table 2 sets the nominal flow rates of the halide standards and diluent gases required to produce the calibration gas composition. Table 2 also provides the capillary inlet and outlet pressures that will produce the desired halide standard flow. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com