Automatic knocking robot detection system for detecting flaws in building structure

A detection system and building structure technology, applied in the field of robots, can solve problems such as cumbersome installation, high cost, and incomplete detection, and achieve the effects of high detection efficiency, low cost, and saving construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The structure will be further described below in conjunction with the accompanying drawings of the description.

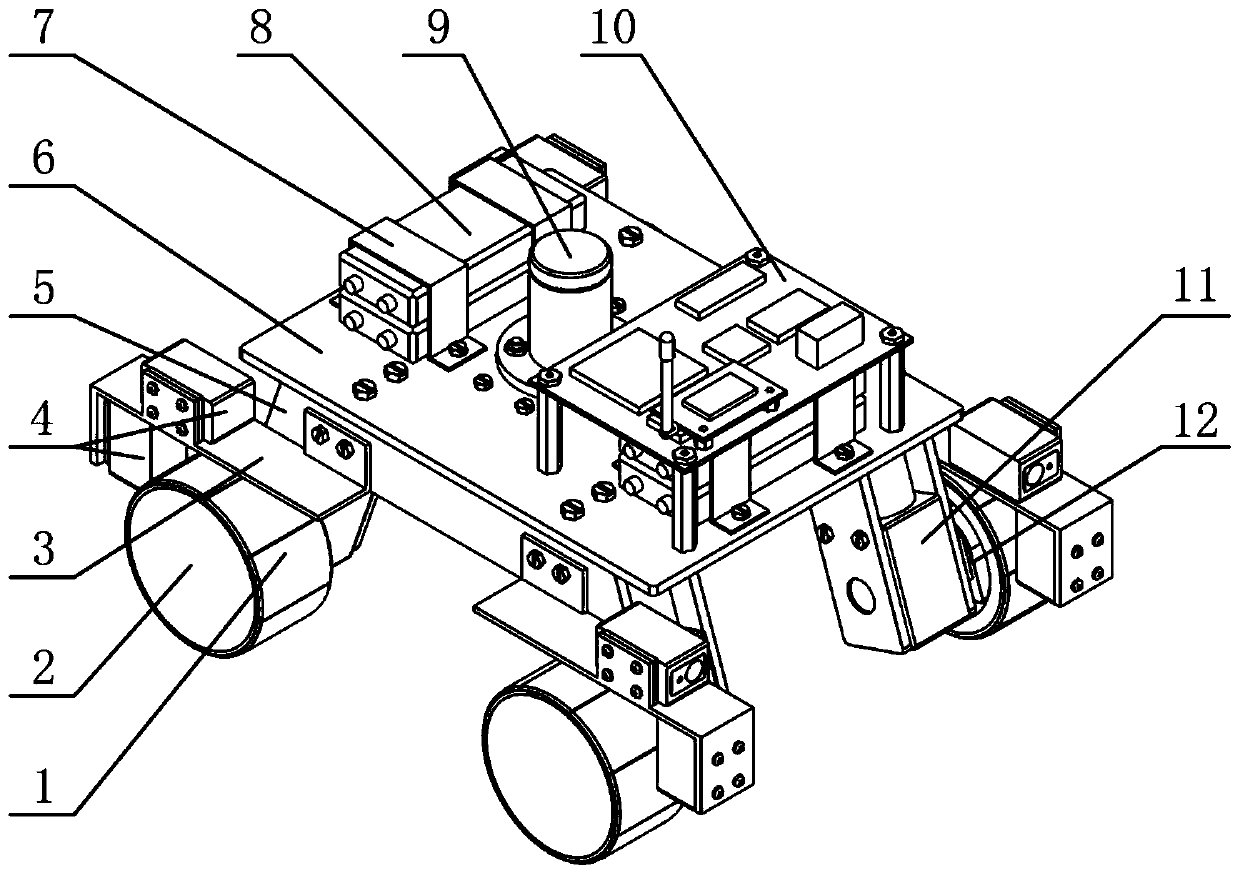

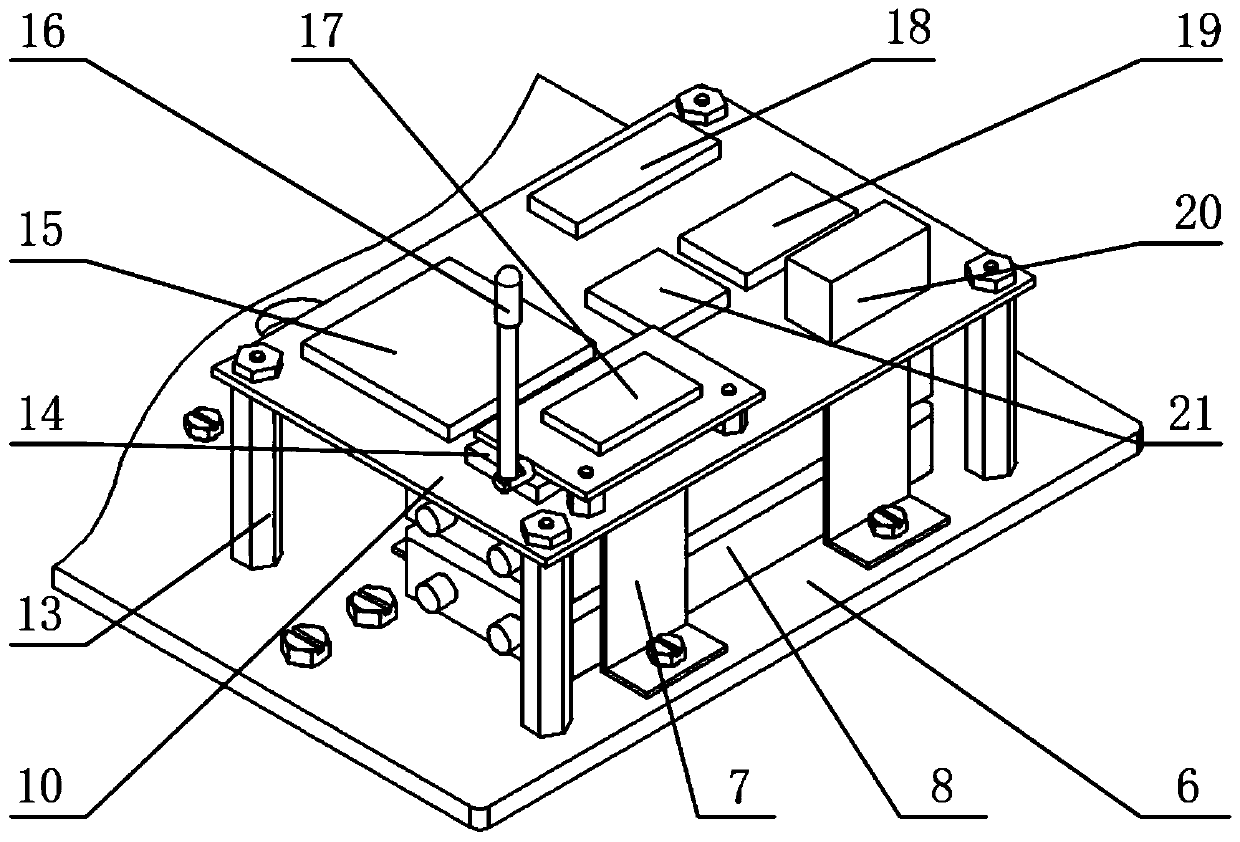

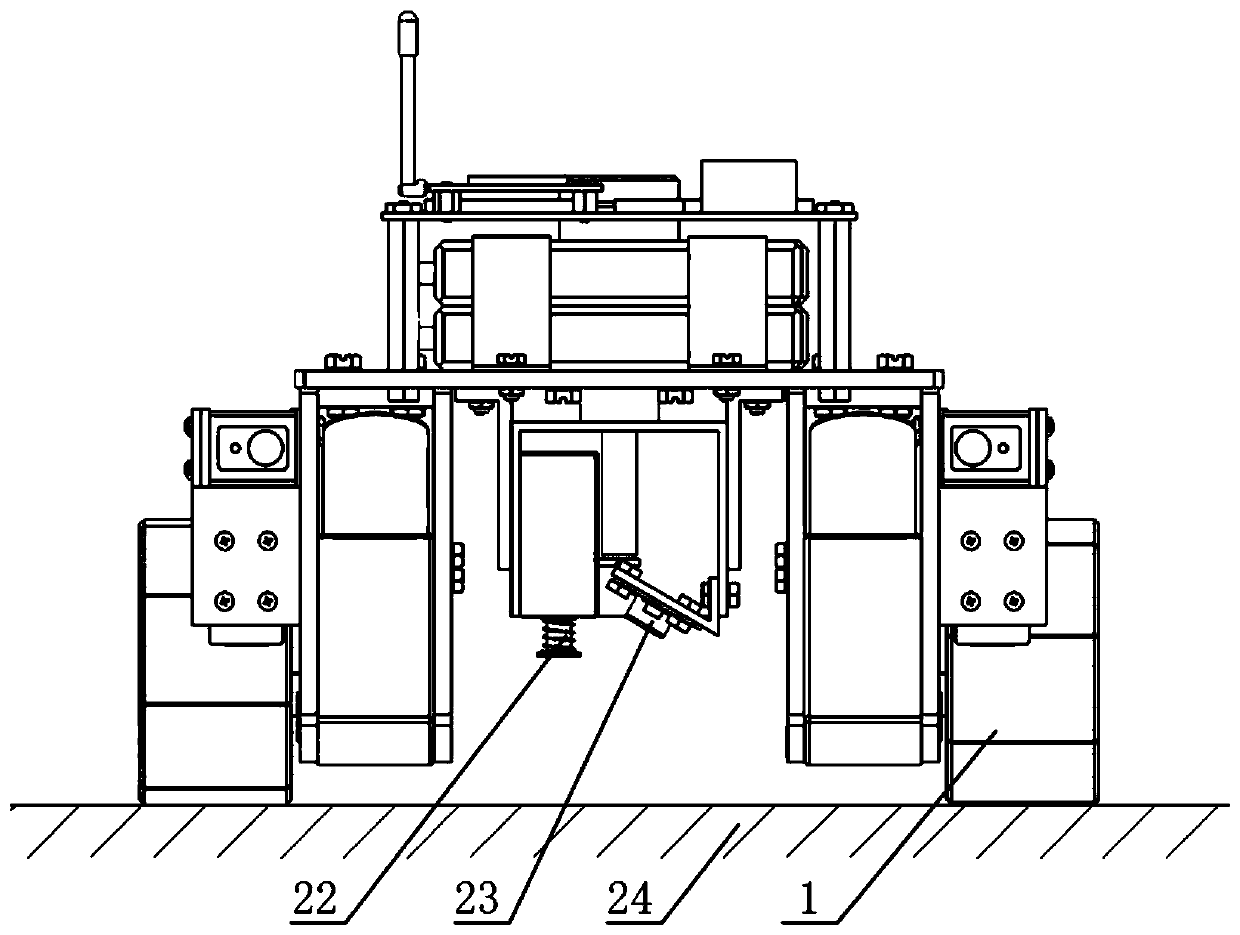

[0029] refer to Figure 1 to Figure 5 , an automatic percussion robot detection system for flaw detection of building structures, including a mobile module, a control module 10, an electromagnetic percussion type damage detection module and a laser ranging sensor 4, the mobile module includes a vehicle frame 6, two wheel frames 5. Four sets of magnetic wheels, two sets of batteries 8 and battery fixing pieces 7, each set of magnetic wheels contains eight pieces of bar magnets 1, one wheel 2, one right-angle motor 11 and one encoder 12, used for the frame 6 of the mobile module For the installation of the wheel frame 5, the battery fixing piece 7, the DC motor 9, the control module 10, and the electromagnetic percussion damage detection module, the four sets of magnetic wheels of the mobile module are composed of a bar magnet 1 wrapped around the wheel 2, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com