A kind of preparation method of magnetic layered molybdenum disulfide nanosheet

A molybdenum disulfide, magnetic layer technology, applied in the directions of molybdenum sulfide, nanotechnology, nanotechnology, etc., can solve problems such as no reports on the preparation of magnetic molybdenum disulfide nanosheets, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

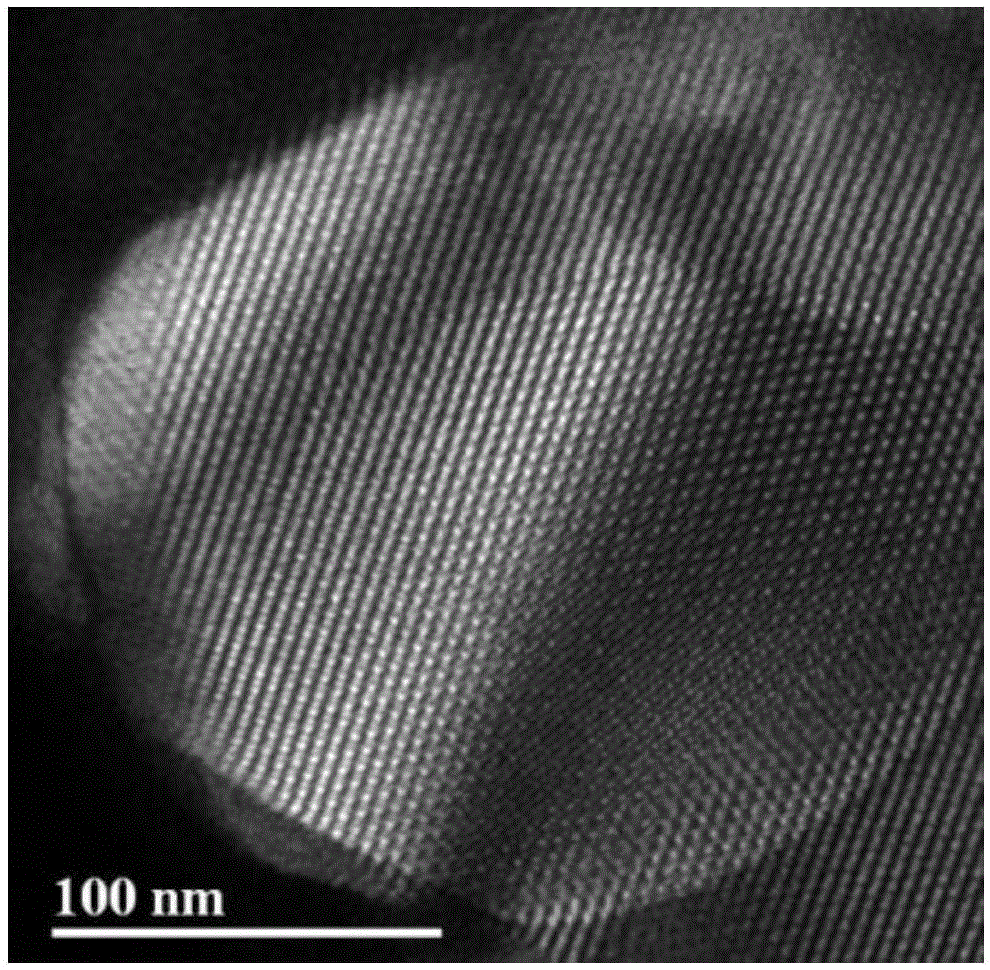

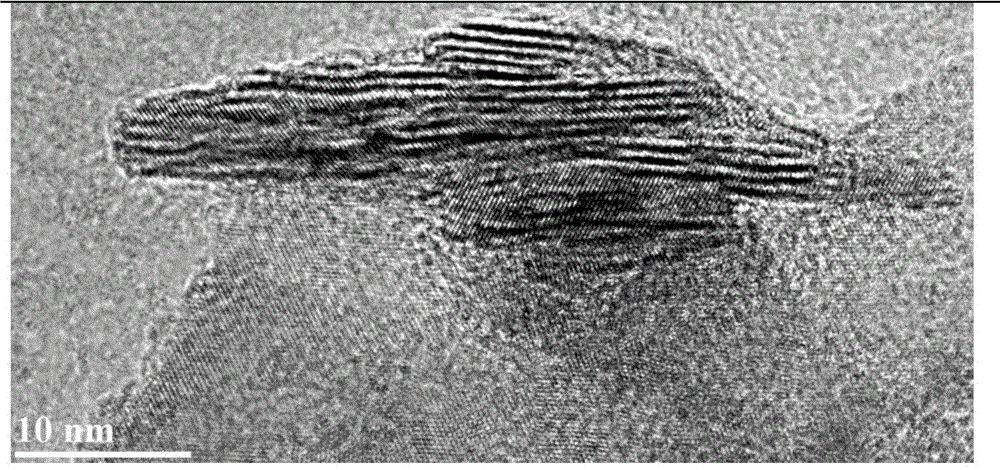

[0025] Step 1: Molybdenum disulfide (MoS 2 ) stripping. Molybdenum disulfide raw material powder (SigmaAldrich, 1 μm) was weighed and added to N-methylpyrrolidone (stripping solvent) to prepare a molybdenum disulfide dispersion with an initial concentration of 0.1 mg / ml. Then put it into the first ultrasound machine for ultrasound for 2 hours, and then transfer to the second ultrasound machine for 8 hours of ultrasound.

[0026] Among them, the choice of stripping solvent is based on the range of surface tension. Through theoretical calculation, the surface tension of the organic solvent ranges from 40 to 65mJ / m 2 (25°C), the purpose of exfoliating single-layer, double-layer and multilayer molybdenum disulfide nanosheets can be achieved. The surface tension of the N-methylpyrrolidone of the present embodiment is 41.0mJ / m 2 (25°C), very suitable for the application of the present invention. Since the operating temperature has a direct impact on the surface tension of the o...

Embodiment 2

[0034] Step 1: Molybdenum disulfide (MoS 2 ) stripping. Weigh molybdenum disulfide raw material powder (SigmaAldrich, 1 μm) and add to benzaldehyde (stripping solvent, surface tension 40.72mJ / m 2(25°C)), prepare a molybdenum disulfide dispersion with an initial concentration of 0.5mg / ml. Then control the temperature at 25-35°C, put it into the first sonicator for 0.5h of sonication, and then transfer to the second sonicator for 4h of sonication.

[0035] Step 2: Centrifuge the molybdenum disulfide dispersion after ultrasonic dispersion, control the centrifugation speed to 2000rpm, and centrifuge for 30min. Then remove the precipitate separated by centrifugation, collect the upper suspension and filter to remove the benzaldehyde stripping solvent. The filter membrane is a PTFE filter membrane with a diameter of 47mm (Milliporefilter). Finally, the filter cake obtained by filtering is dried in a vacuum oven at 60°C, and the stripping solvent is volatilized to obtain molybden...

Embodiment 3

[0037] Step 1: Molybdenum disulfide (MoS 2 ) stripping. Weigh molybdenum disulfide raw material powder (SigmaAldrich, 1 μm) and add it to the stripping solvent formed by cetyltrimethylammonium chloride-isopropanol mixed solution (the concentration of cetyltrimethylammonium chloride is 0.01-0.2 mol / L, the surface tension is about 58mJ / m 2 (25°C)), prepare a molybdenum disulfide dispersion with an initial concentration of 1.5mg / ml. Then control the temperature at 25-35°C, put it into the first sonicator for 2 hours of sonication, and then transfer to the second sonicator for 8 hours of sonication.

[0038] Step 2: Centrifuge the ultrasonically dispersed molybdenum disulfide dispersion at a controlled centrifugation speed of 3000 rpm and a centrifugation time of 30 minutes. The precipitate separated by centrifugation was then removed, and the supernatant suspension was collected and filtered to remove the stripping solvent. The filter membrane is a PTFE filter membrane with a...

PUM

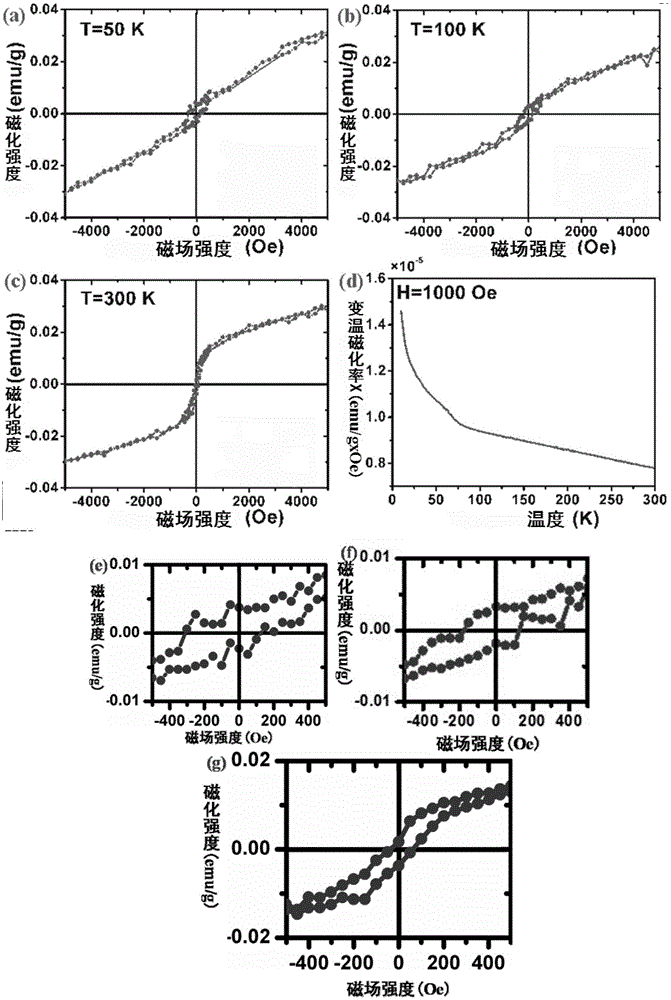

| Property | Measurement | Unit |

|---|---|---|

| magnetic susceptibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com