Bismuth ferrite powder and preparation method thereof

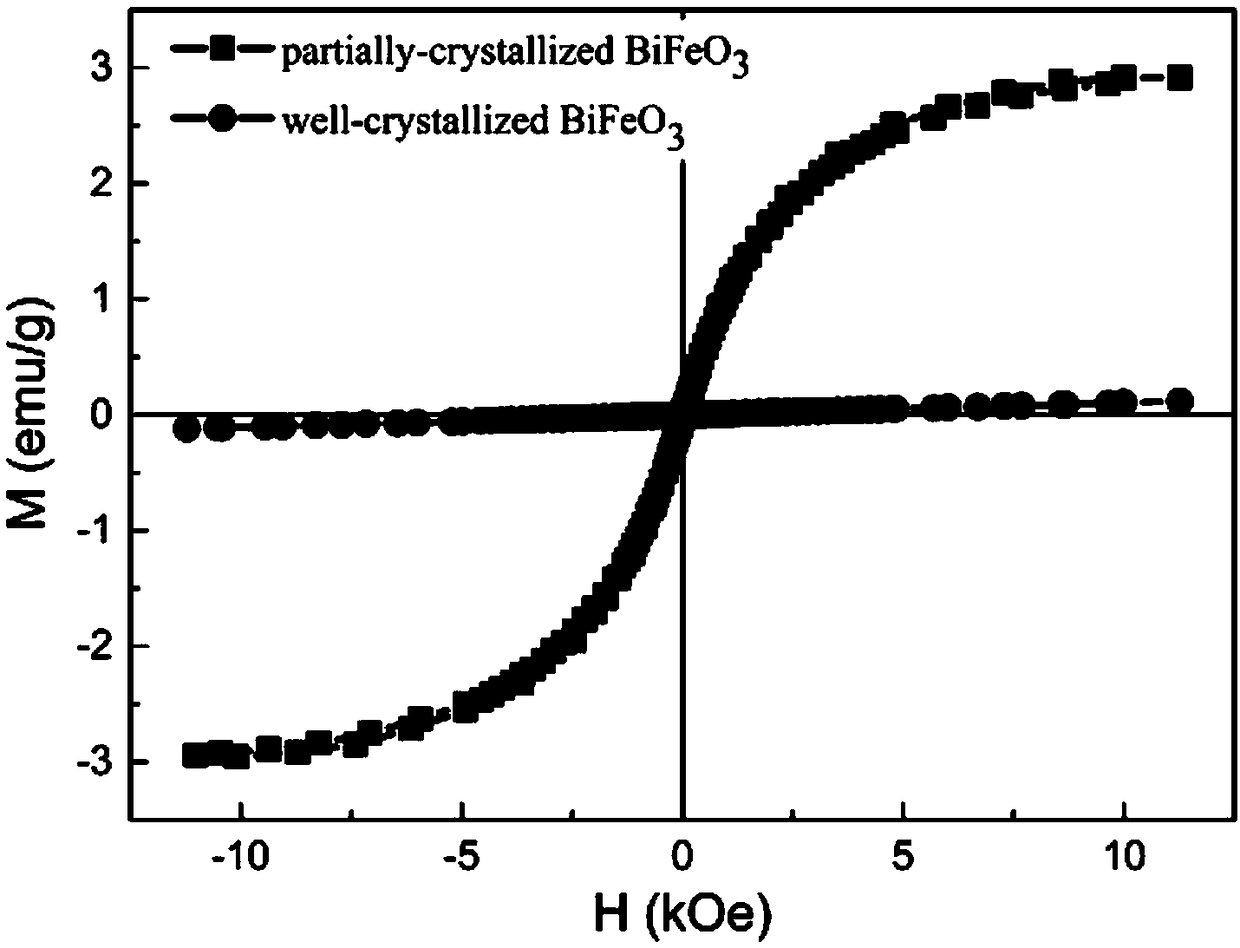

A technology of bismuth ferrite and powder, which is applied in chemical instruments and methods, iron compounds, inorganic chemistry, etc., can solve the problems of not showing ferromagnetism, and achieve the effect of good ferromagnetic performance, simple equipment, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

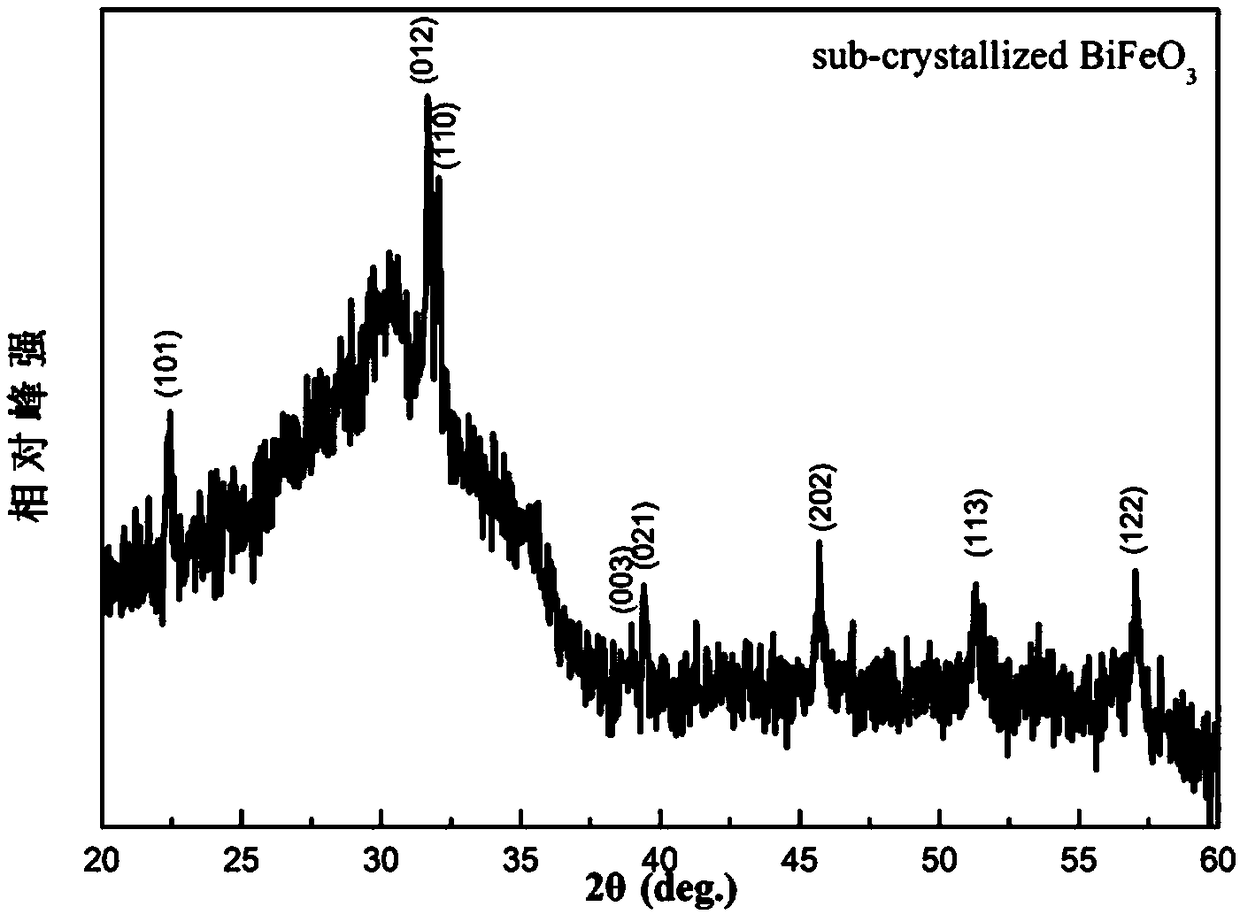

[0030] A kind of bismuth ferrite powder is made of BiFeO 3 The crystalline particles embedded in the amorphous structure of BiFeO 3 form.

[0031] The preparation method of this bismuth ferrite powder, comprises the steps:

[0032] (1) Take 0.5mmol Bi(NO 3 ) 3 ·5H 2 O and 0.5mmol Fe(NO 3 ) 3 9H 2 O, 8% SDS in water containing 0.6 mmol of SDS, 1 ml concentrated HNO 3 (mass fraction concentration ≥ 68%), add distilled water and mix to form an 8ml solution;

[0033] (2) Add ammoniacal liquor dropwise to the mixed solution obtained in step (1), and keep stirring until the pH value of the solution is 9, leave to stand for stratification, and remove the lower layer of precipitation;

[0034] (3) repeatedly washing and centrifuging the precipitate obtained in step (2) with deionized water to obtain a reaction precipitate;

[0035] (4) Add the precipitate obtained in step (3) into 16ml 10mol / L KOH aqueous solution, stir for 20min and mix well;

[0036] (5) Move the mixed so...

Embodiment 2

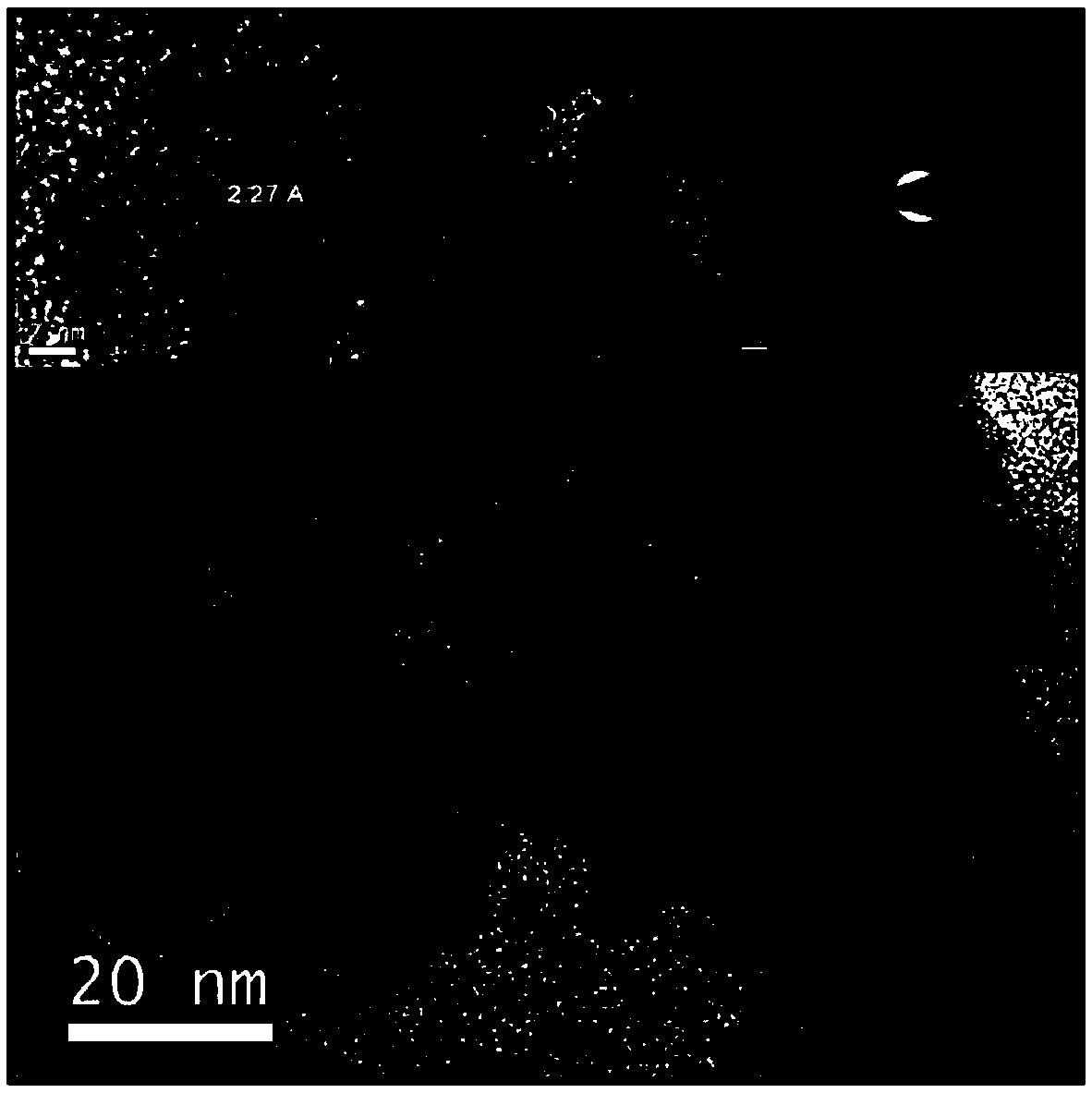

[0039] A kind of bismuth ferrite powder is made of BiFeO 3 The crystalline particles embedded in the amorphous structure of BiFeO 3 formed where the BiFeO 3 The crystal particle diameter is 5-20nm.

[0040] The preparation method of this bismuth ferrite powder, comprises the steps:

[0041] (1) Take 0.5mmol Bi(NO 3 ) 3 ·5H 2 O and 0.5mmol Fe(NO 3 ) 3 9H 2 O, 12% SDS in water containing 0.65 mmol of SDS, 0.9 ml concentrated HNO 3 (mass fraction concentration ≥ 68%), add distilled water and mix to form a 10.8ml solution;

[0042] (2) Add ammoniacal liquor dropwise to the mixed solution obtained in step (1), and keep stirring until the pH value of the solution is 10, leave to stand for stratification, and remove the lower layer of precipitation;

[0043] (3) repeatedly washing and centrifuging the precipitate obtained in step (2) with deionized water to obtain a reaction precipitate;

[0044] (4) Add the precipitate obtained in step (3) into 16.2ml 18mol / L KOH aqueous so...

Embodiment 3

[0048] A kind of bismuth ferrite powder is made of BiFeO 3 The crystalline particles embedded in the amorphous structure of BiFeO 3 formed where the BiFeO 3 The crystal particle diameter is 5-20nm.

[0049] The preparation method of this bismuth ferrite powder, comprises the steps:

[0050] (1) Take 0.5mmol Bi(NO 3 ) 3 ·5H 2 O and 0.5mmol Fe(NO 3 ) 3 9H 2 O, 10% SDS in water containing 0.6 mmol of SDS, 1 ml concentrated HNO 3 (mass fraction concentration ≥ 68%), add distilled water and mix to form a 10ml solution;

[0051] (2) Add ammoniacal liquor dropwise to the mixed solution obtained in step (1), and keep stirring until the pH value of the solution is 9.5, leave to stand for stratification, and remove the lower layer of precipitation;

[0052] (3) repeatedly washing and centrifuging the precipitate obtained in step (2) with deionized water to obtain a reaction precipitate;

[0053] (4) Add the precipitate obtained in step (3) into 18ml 12mol / L KOH aqueous soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com