Preparation method for sandstone paster stone

A technology for veneer stone and sandstone, applied in the field of imitation stone, can solve the problems of unfavorable ecology of natural stone, environmental protection, difficult transportation and construction, unstable pattern of veneer stone, etc. Not easy to fade, firm and maintain the effect of sandstone effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

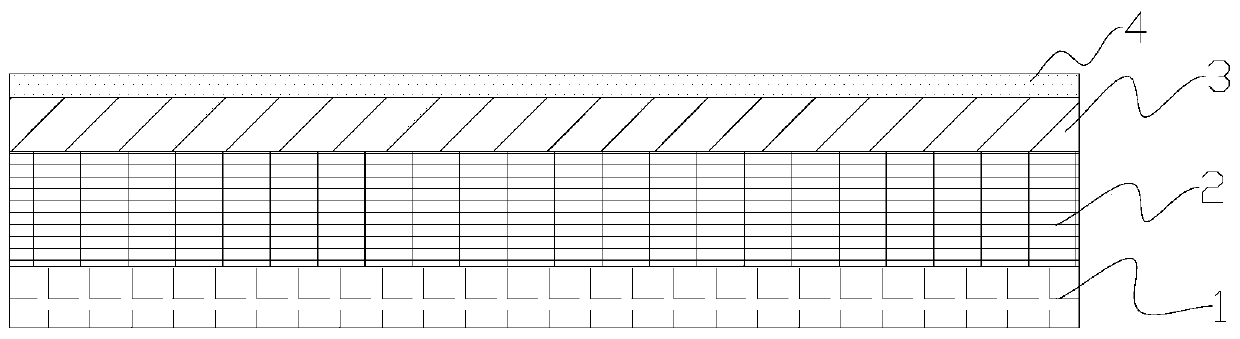

[0053] The invention provides a preparation process for sandstone veneer stone, the steps comprising:

[0054] (1) laying reinforced plastic fiber mesh cloth 1;

[0055] (2) coating a sandstone texture texture paint, drying after coating to form a sandstone texture texture paint layer 2, its thickness is about 1.5mm; the sandstone texture texture paint composition is calculated in parts by weight: 5 parts of water, hydroxyethyl fiber 0.5 parts of prime, 0.2 parts of dispersant, 5 parts of emulsion, and 80 parts of inorganic powder; the gradation of inorganic powder is 70 parts of 10-50 mesh inorganic powder, and 10 parts of 50-200 mesh inorganic powder.

[0056] The emulsion is one or more combinations of pure acrylic, silicon acrylic, styrene acrylic, and fluorosilicone acrylic emulsions, which can improve the acid and alkali resistance, weather resistance, and aging resistance of the patch stone. The performance of the texture coating, and the waterproof effect is particula...

Embodiment 2

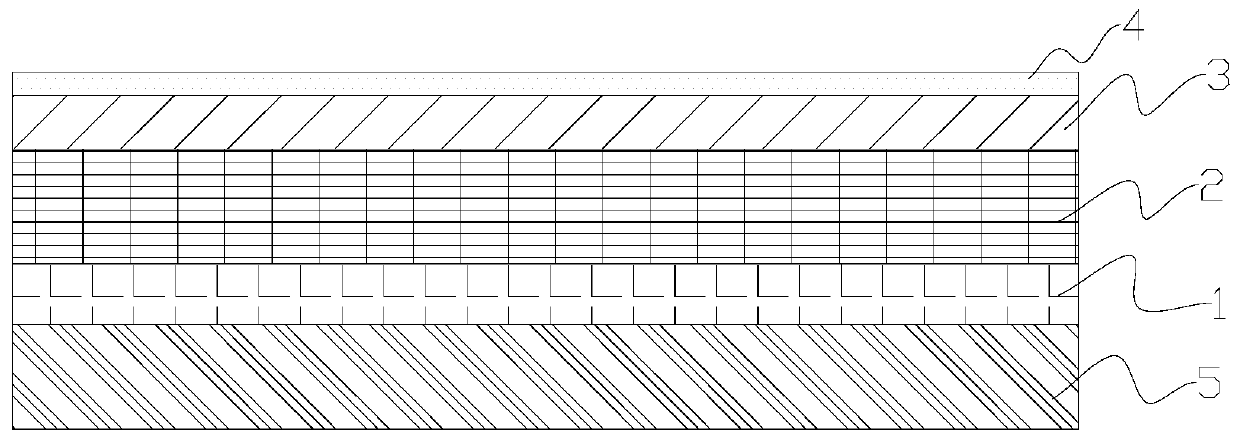

[0063] The invention provides a preparation process for sandstone veneer stone, the steps comprising:

[0064] (1) laying metal fiber mesh cloth 1;

[0065] (2) Apply sandstone texture texture paint twice, dry after coating each time; dry to form sandstone texture texture paint layer 2 after coating, its thickness is about 3mm;

[0066] The composition of the sandstone texture coating for the first time is in parts by weight: 20 parts of water, 0.1 part of bactericide, 0.3 part of cellulose ether, 30 parts of emulsion, and 50 parts of inorganic powder of 10-50 mesh;

[0067] The composition of coating sandstone texture texture coating for the second time is calculated in parts by weight: 20 parts of water, 0.1 part of bactericide, 0.3 part of cellulose ether, 30 parts of emulsion, 70 parts of inorganic powder; wherein the gradation of inorganic powder is 60 parts of inorganic powder of 10-50 mesh, 5 parts of inorganic powder of 50-200 mesh, and 5 parts of inorganic powder of ...

Embodiment 3

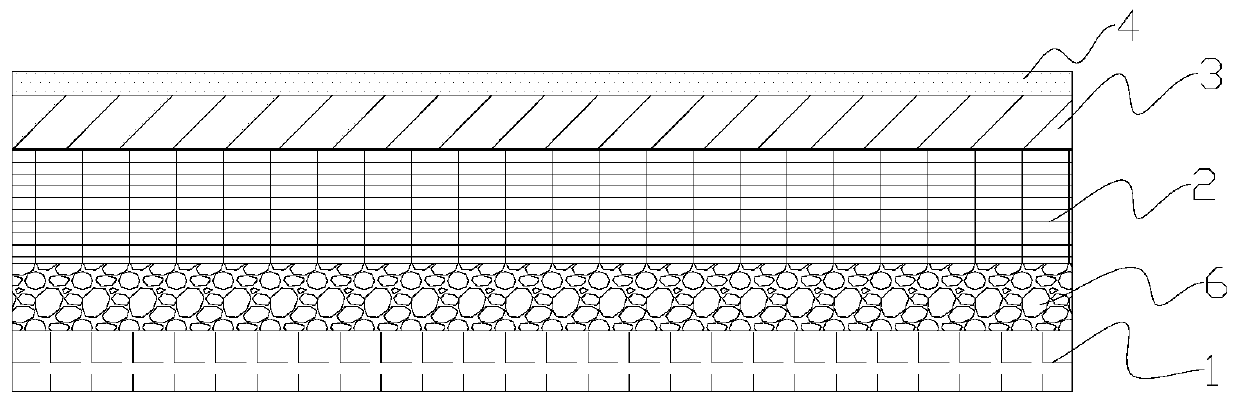

[0075] The invention provides a preparation process for sandstone veneer stone, the steps comprising:

[0076] (1) laying non-woven fabric 1;

[0077] (2) Sandstone texture texture coating is coated three times, drying after each coating; drying after coating forms sandstone texture texture coating layer 2, and its thickness is about 3mm;

[0078] The composition of the sandstone texture coating for the first time is in parts by weight: 15 parts of water, 0.2 parts of bactericide, 0.2 part of cellulose ether, 0.1 part of dispersant, 25 parts of emulsion, and 70 parts of inorganic powder; wherein the inorganic powder The body gradation is 75 parts of 30-50 mesh inorganic powder, 10 parts of 50-200 mesh inorganic powder;

[0079] The composition of sandstone texture coating for the second time is calculated in parts by weight: 15 parts of water, 0.2 part of bactericide, 0.2 part of cellulose ether, 0.1 part of dispersant, 25 parts of emulsion, 70 parts of inorganic powder; wher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com