A kind of fiber soil mixed spraying method

A soil and fiber technology, applied in botanical equipment and methods, excavation, planting substrates, etc., can solve problems such as easy blockage of spray pipe fittings, and achieve the effect of rapidly improving soil structure, strong adhesion, and increasing organic matter content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1 One Fiber Soil Mixed Sport Method

[0029] The propagation method is mixed with water, and the mix is mixed by the stroke, and then sprayed on the slope surface.

[0030] The inadvertent matrix includes heat treatment wood fibers, soil; each cubic soil (i.e., 1.4 tons) is added to 5000 grams of heat treatment wood fiber.

[0031] The heat treatment wood fiber: is a porous fiber, a length of 1.5-2.5 cm, a diameter of 0.05-0.15 mm; a fiber content having a length of 2 ㎝ ≥ 50%.

[0032] The preparation method of heat treatment wood fibers: pyrolysis is formed by bark, crushed wood or the like under high temperature high pressure conditions; high temperature and high pressure conditions: The high temperature high pressure condition: pressure is 345 kPa, the temperature is 193 ° C.

Embodiment 2

[0033] Example 2 One Fiber Soil Mixed Sport Method

[0034] The propagation method is mixed with water, and the mix is mixed by the stroke, and then sprayed on the slope surface.

[0035] The prevocation matrix includes heat treatment wood fibers, soil; 4000 g of heat treatment wood fibers is added per cubic soil (ie, 1.4 tons).

[0036] The heat treatment wood fiber: is a porous fiber, a length of 1.5-2.5 cm, a diameter of 0.05-0.15 mm; a fiber content having a length of 2 ㎝ ≥ 50%.

[0037] The preparation method of heat treatment wood fibers: is picked up by bark, crushed wood or the like under high temperature and high pressure conditions; high temperature and high pressure conditions: 350 kPol, temperature is 190 ° C.

Embodiment 3

[0038] Example 3 One Fiber Soil Mixed Sport Method

[0039] The propagation method is mixed with water, and the mix is mixed by the stroke, and then sprayed on the slope surface.

[0040] The inadvive matrix includes heat treatment wood fibers, soil; each cubic soil (i.e., 1.4 tons) is added 3000 grams of heat treatment wood fiber.

[0041] The heat treatment wood fiber: is a porous fiber, a length of 1.5-2.5 cm, a diameter of 0.05-0.15 mm; a fiber content having a length of 2 ㎝ ≥ 50%.

[0042] The preparation method of heat treatment wood fibers: is picked up by bark, crushed wood or the like under high temperature and high pressure conditions; high temperature high pressure conditions: pressure of 340 kPa, temperature is 195 ° C.

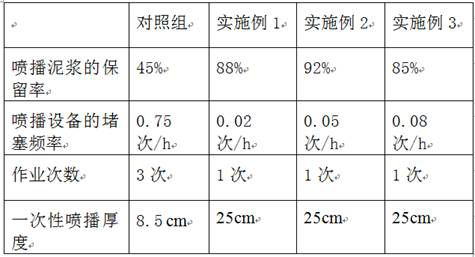

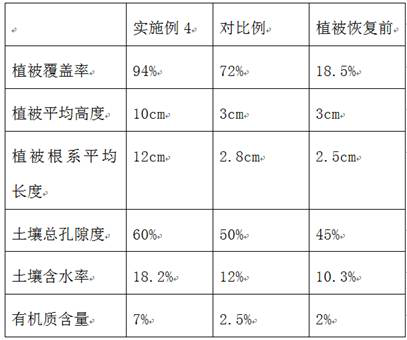

[0043] After experimenting, the water content made of fiber soil mixed by the inversion method was adopted on the slope of the slope ratio of 1: 2; Group; inading thickness of 25cm; after inversion, simulation 5mm / h rainfall, uniformly sprinkled int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com