Multi-hole tantalum rod and preparation method thereof

A technology of porous tantalum and multi-level pores, applied in bone implants, etc., can solve the problems of poor bone conduction and bone fusion performance, uneven distribution of pore structure, poor matching of mechanical properties, etc., and achieve excellent performance and adjustable mechanical properties , evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention also provides a method for preparing a porous tantalum rod described in the above technical solution, comprising the following steps:

[0031] (1) Construct the three-dimensional model of the above-mentioned porous tantalum rod in the three-dimensional software model;

[0032] (2) After determining the printing direction of the three-dimensional model obtained in the step (1) and setting the substrate, the three-dimensional model is layered, and the layered processing includes dividing the three-dimensional model into layers with the same thickness along the printing direction. 3D structure, save and import the file in the corresponding format;

[0033] (3) Import the format file obtained in the step (2) into a 3D printer for 3D printing to obtain a porous tantalum rod.

[0034] The present invention constructs the three-dimensional model of the porous tantalum rod in the three-dimensional software model.

[0035] The present invention has no spe...

Embodiment 1

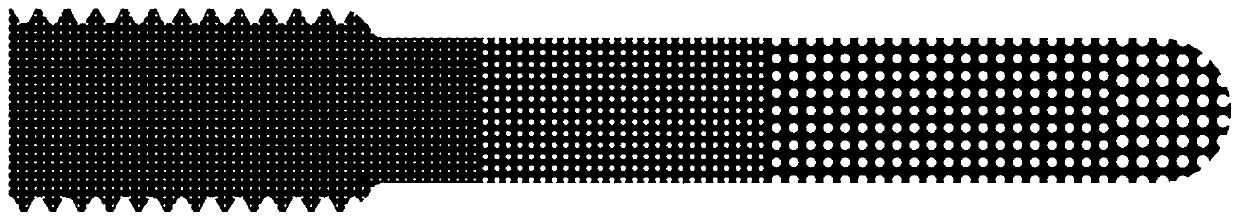

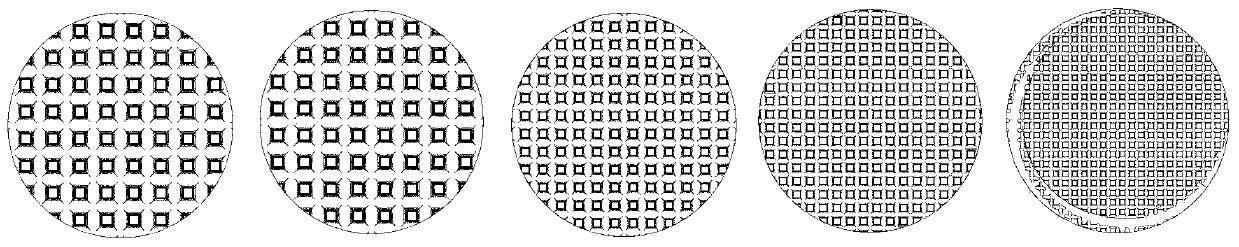

[0044] A porous tantalum rod, the porous tantalum rod includes a threaded part and a multi-stage hole part, the threaded part and the multi-stage hole part are penetrated by three-dimensional circular holes; the three-dimensional circular holes are arranged in a row; the threaded part The length is 30mm, the thread outer diameter of the threaded part is 14mm, the inner diameter is 12mm, the middle diameter is 13mm, the pitch is 2mm, the number of threads is 1, the lead is 2mm, the rise angle is 4°, and the thread angle is trapezoidal; The diameter of the multi-stage hole is 10 mm, and the length is 70 mm; the multi-stage hole includes a three-stage porous structure; the diameters of the circular holes of the three-stage porous structure are respectively 300 μm, 500 μm and 800 μm, and in the multi-stage hole The length of the porous structure with a pore diameter of 300 μm is 5 mm, the length of the porous structure with a pore diameter of 500 μm in the hierarchical pore part is 2...

Embodiment 2

[0052] A porous tantalum rod, the porous tantalum rod includes a threaded part and a multi-stage hole part, the threaded part and the multi-stage hole part are penetrated by three-dimensional circular holes; the three-dimensional circular holes are arranged in a row; the threaded part The length is 30mm, the thread outer diameter of the threaded part is 14mm, the inner diameter is 12mm, the middle diameter is 13mm, the pitch is 2mm, the number of threads is 1, the lead is 2mm, the rise angle is 4°, and the thread angle is trapezoidal; The diameter of the multi-stage hole is 10 mm, and the length is 70 mm; the multi-stage hole includes four sections of porous structure; the three-dimensional circular holes of the four sections of porous structure are respectively 200 μm, 400 μm, 600 μm and 800 μm; the multi-level The length of the porous structure with a diameter of 200 μm in the hole is 10 mm, the length of the porous structure with a diameter of 400 μm in the multi-level hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com