Manufacturing process of full carbon fiber afo ankle-foot prosthesis

A manufacturing process, carbon fiber technology, applied in the field of medical devices, can solve the problems of ineffective prevention of foot deformity, poor prevention effect of foot deformity, lack of forefoot rolling characteristics, etc., to achieve the effect of guaranteed strength, convenient wearing, and increased cushioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

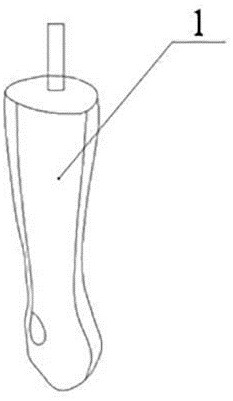

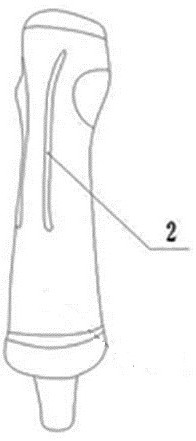

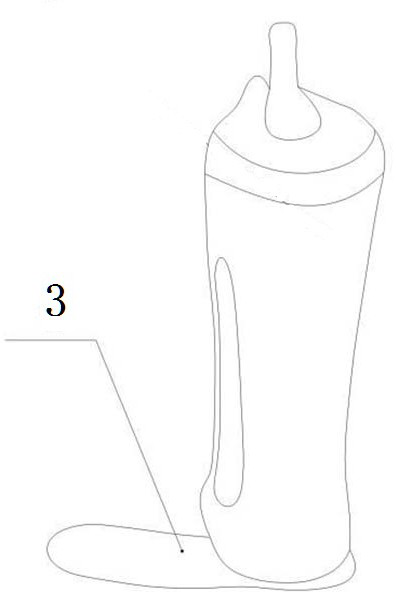

[0034] The present invention is further explained in detail in conjunction with the attached drawings. In the accompanying drawings, each mark is: 1: positive type; 2: reinforcement bar; 3: foot plate; 4: shell; 5: inner lining; set.

[0035] The manufacturing process of the full carbon fiber AF0 ankle-foot prosthesis comprises the following steps:

[0036] A: Take the type, including the following steps:

[0037]A1: Preparation tools: cling film, shape-taking pen, water, knife, scissors, plaster bandage, cutting strips, calipers, tape measure, ask the patient to sit on a chair with the knee flexed at 90° and the ankle at 0°, wrap the affected limb Plastic wrap; draw the bony marks and the pressure-free parts of the residual limb, the highest point of the medial longitudinal arch of the residual foot, the highest point of the lateral longitudinal arch, the medial malleolus, the lateral malleolus, the Achilles tendon, the thinnest and thickest part of the calf, and review the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com