Method for preparing pressing type barium-tungsten cathode through microwave sintering

A technology of microwave sintering and barium tungsten cathode, which is applied to other manufacturing equipment/tools, mechanical equipment, engine components, etc., can solve the problems of poor emission performance and grain growth, and achieve improved emission performance, significant growth, and emission current The obvious effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

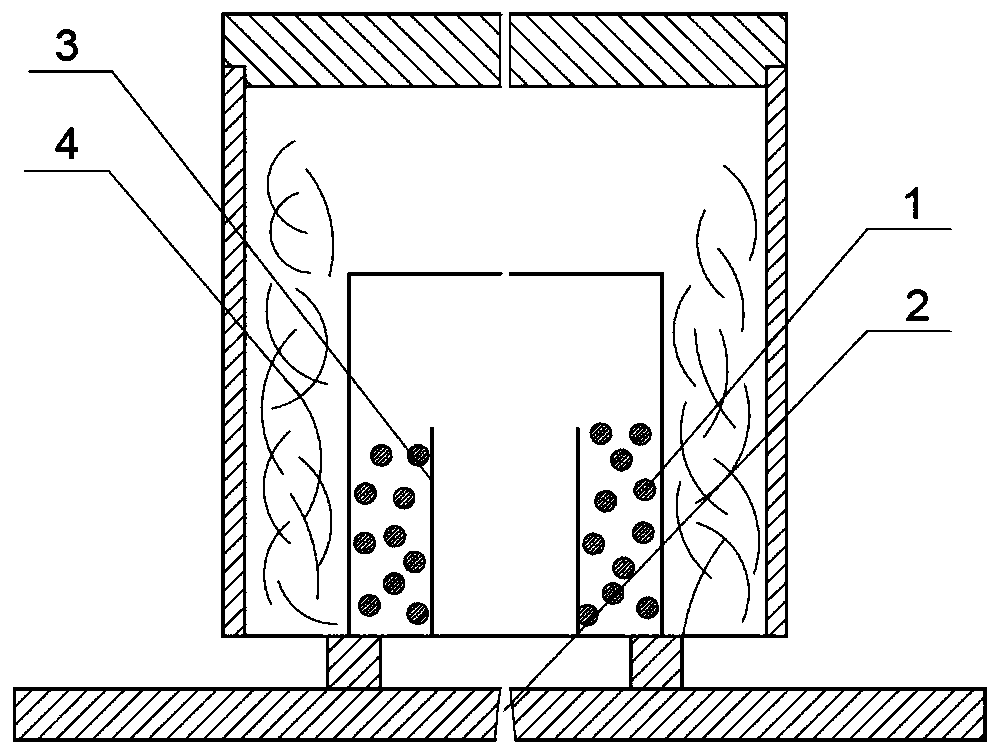

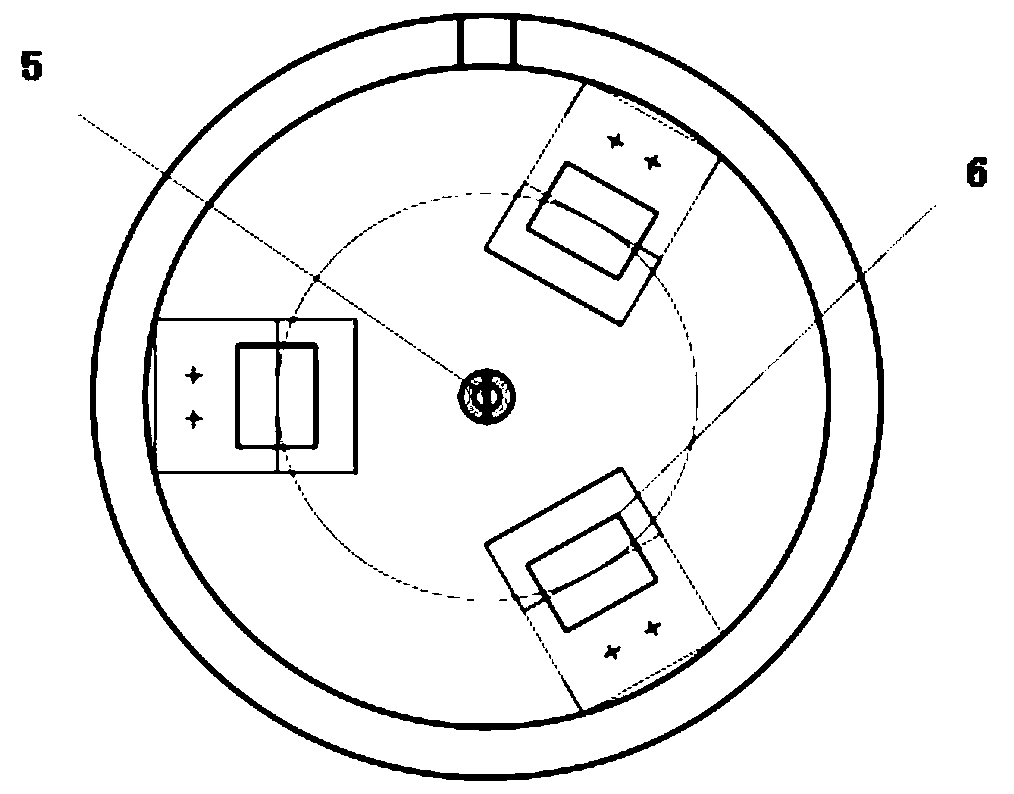

Image

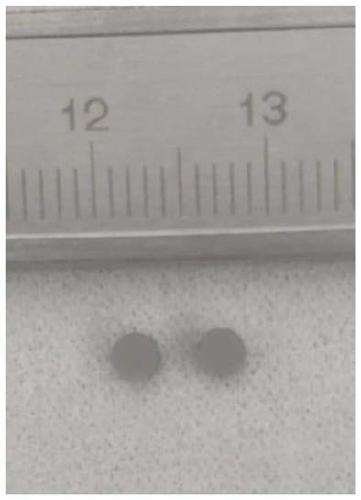

Examples

Embodiment 1

[0025] The invention provides a method for preparing a pressed barium tungsten cathode by microwave sintering, which comprises the following steps:

[0026] (1) Take 3 100ml beakers that have been cleaned and dried with deionized water, and the analytically pure Ba(NO 3 ) 2 , Ca(NO 3 ) 2 4H 2 O, Al(NO 3 ) 3 9H 2 O, according to c(BaO):c(CaO):c(Al 2 o 3 ) into beakers at a ratio of 4:1:1, pour an appropriate amount of deionized water, and prepare aqueous solutions of barium nitrate, calcium nitrate, and aluminum nitrate respectively, and use a stirrer to fully stir until the three solutions are completely free. The precipitate is transparent.

[0027] (2) Mix the three solutions prepared in step (1), and then stir again until the solution is transparent without precipitation.

[0028] (3) Take a 300ml beaker that has been cleaned and dried with deionized water, put analytically pure ammonium metatungstate into the beaker, pour in an appropriate amount of deionized wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com