Device and process for extracting mirabilite from lithium deposition mother liquor for producing lithium salt from lithium mica

A technology of lepidolite and lithium precipitation, which is applied in the fields of alkali metal sulfite/sulfate purification, solution crystallization, chemical instruments and methods, etc., which can solve frequent parking and cleaning cycles, high energy consumption of recovery process, long crystallization time, etc. problems, to achieve the effect of preventing equipment blockage, reducing investment costs, and reducing temperature differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

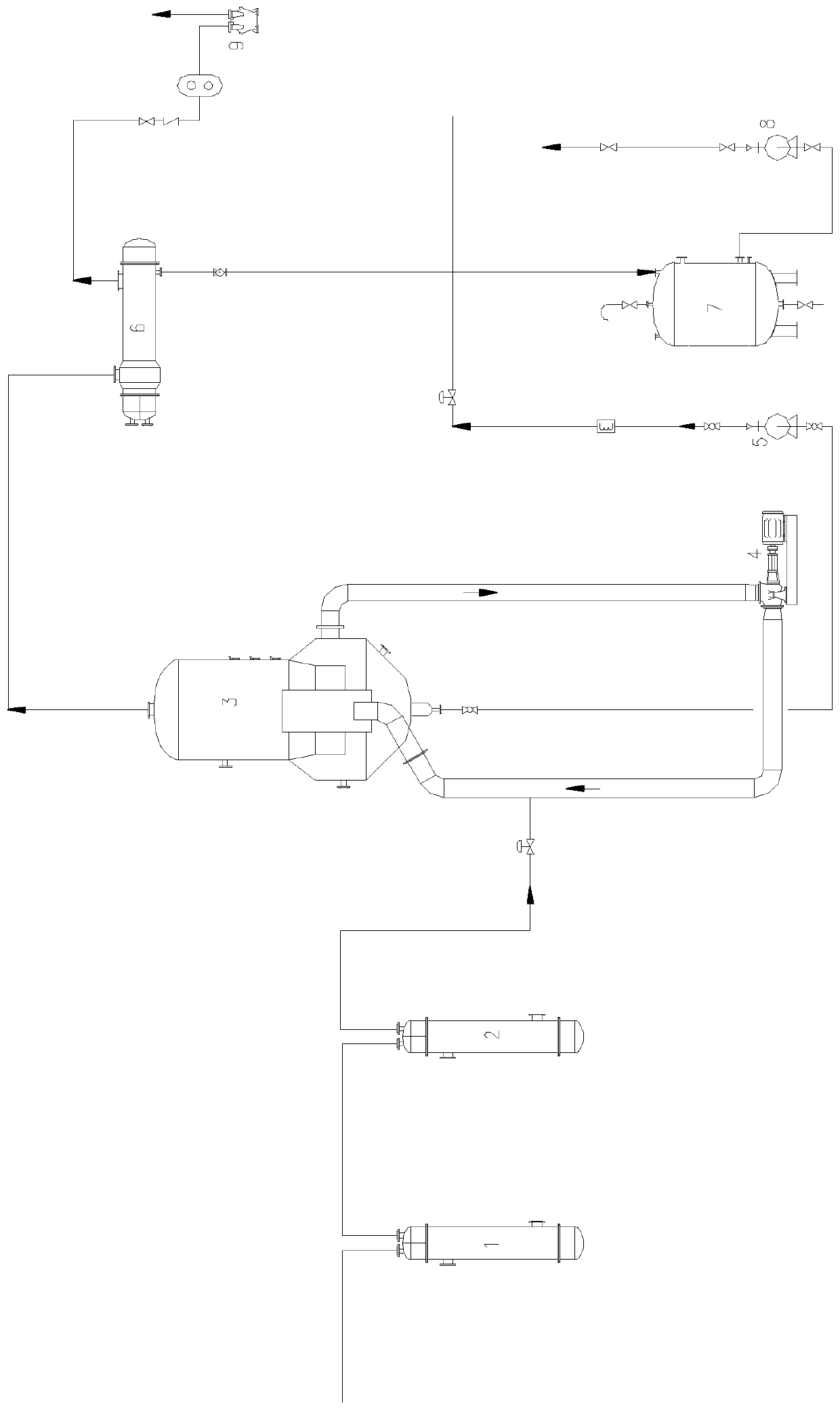

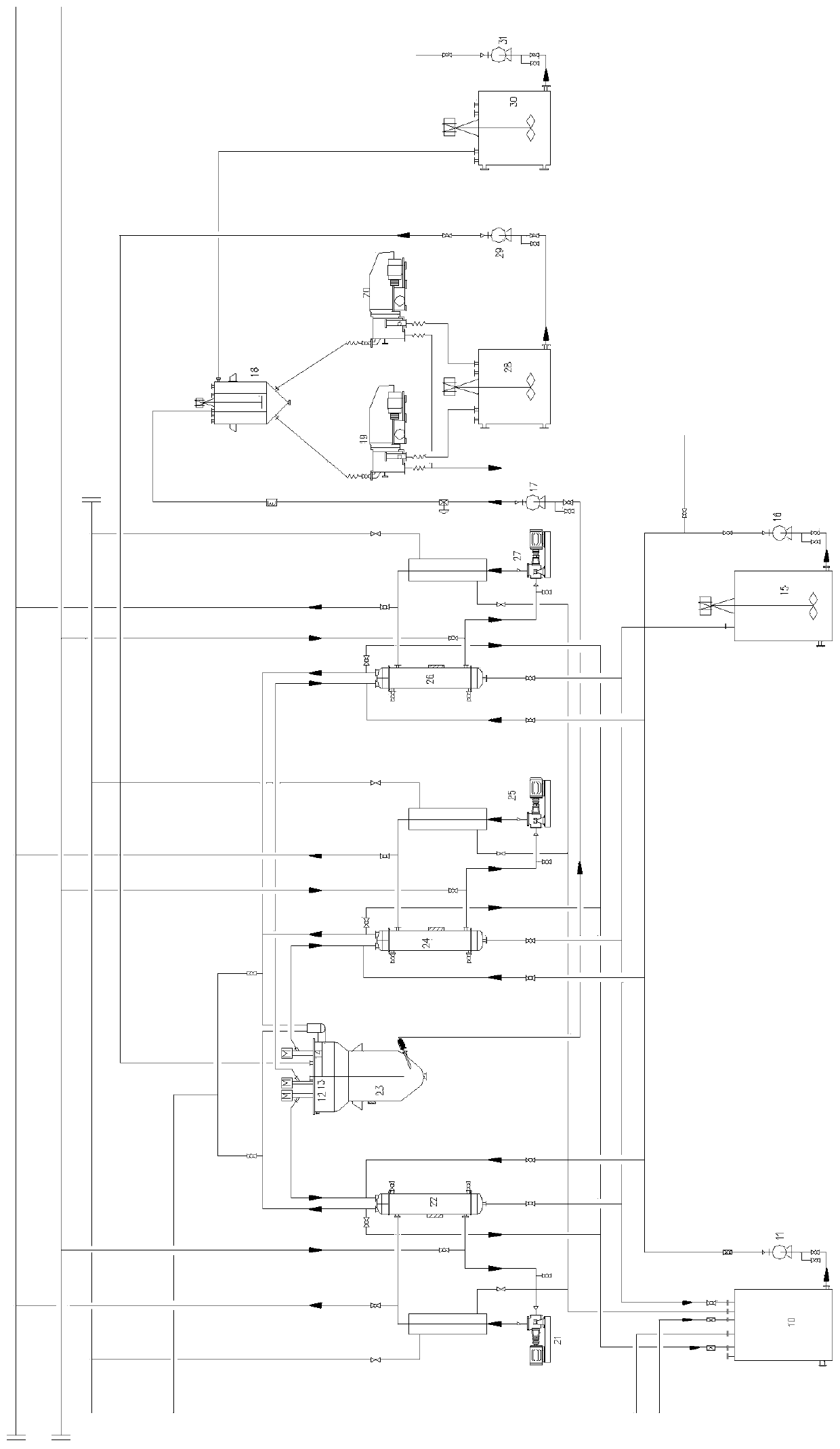

[0029] The invention provides a device for extracting Glauber's salt from lithium salt preprecipitation liquid produced from lepidolite, comprising a flash crystallization device and a freeze crystallization device, the flash crystallization device is connected with the freeze crystallization device, and the flash crystallization device is connected to the freeze crystallization device. The crystallization device is used to perform flash crystallization treatment on the material, and the freeze crystallization device is used to perform freeze crystallization treatment on the flashed material, and the flash crystallization device includes a two-stage precooler, a flash crystallizer 3 and a condenser 6, the two-stage pre-cooler includes a primary pre-cooler 1 and a secondary pre-cooler 2, the pre-cooler is used for preliminary cooling of materials, the pre-cooler and the flash crystallization The upper end of the flash crystallizer 3 is connected to the first exhaust port, and th...

Embodiment 2

[0031] The present invention also provides a process for extracting Glauber's salt from lithium salt preprecipitation liquid produced from lepidolite, comprising the following steps in sequence:

[0032] (1): The front-end lithium sinking liquid passes through the two-stage precooler in turn to reduce the temperature of the feed liquid to 40-45°C;

[0033] (2): The pre-precipitated lithium solution after cooling enters the flash crystallizer 3 to perform vacuum flash evaporation under the action of the flash circulation pump 4, and the flash evaporation temperature is controlled to be 20°C;

[0034] (3): Then, it is sent to the freezing crystallizer 23 through the flash discharge pump 5 to carry out freezing and crystallization through three sets of external coolers, and the circulation is cooled to 0°C-5°C;

[0035] (4): After the crystallization is completed, the material is sent to the thickener 18 by the crystallization discharge pump 17 of the freezing crystallizer 23, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com