Oily waste liquid treatment technology in machinery industry

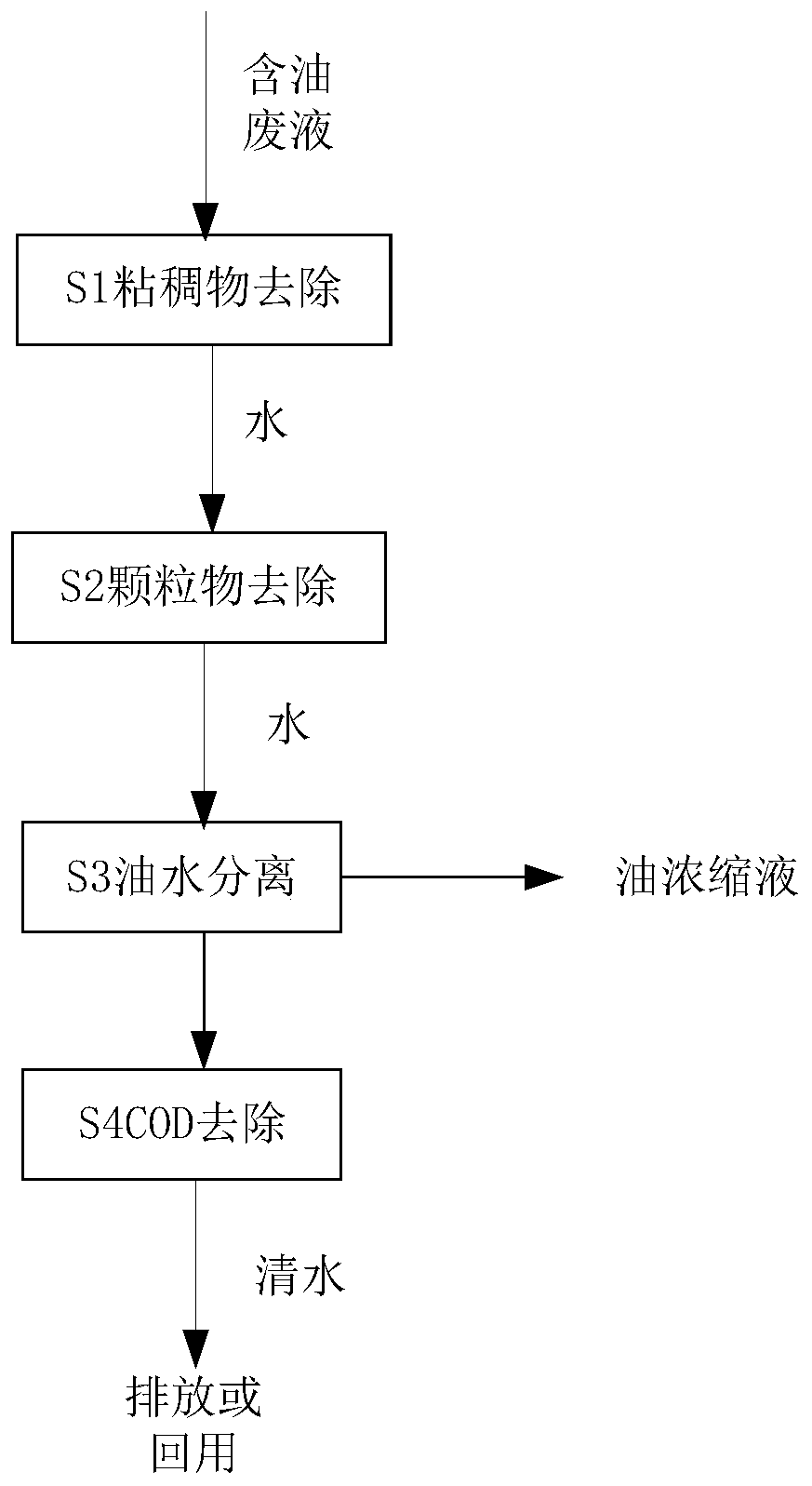

A waste liquid treatment, industry-leading technology, applied in the field of oily waste liquid treatment process in the machinery industry, can solve the problems of reducing the amount of concentrated waste liquid, unstable effluent index, limited water quality range, etc., to optimize the process route and unit equipment, increase heat Transfer efficiency, effect of automatic flushing function design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Waste cleaning liquid from a mechanical processing plant, the waste liquid contains 4% oil, COD value 5000-10000mg / L, suspended solid 1000-3000mg / L, dissolved solid 2000-5000mg / L. The process of the present invention is used to treat the waste cleaning liquid.

[0036] S1: The viscous removal unit is a belt filter, the belt filter adopts a gravity belt filter, the filter cloth is made of ordinary non-woven fabric, the filter cloth precision is 10μm, and viscous and cuttings such as slick oil and paraffin can be removed effective retention. After the oily waste liquid enters the belt filter, it passes through the filter cloth under the action of gravity, the viscous matter is isolated and attached to the filter cloth, and the filtrate enters the liquid tank, and the removal efficiency of the viscous matter is >95%. The belt filter is equipped with a dirt collection box to collect the replaced filter cloth and the sticky matter attached. The belt filter monitors the fil...

Embodiment 2

[0041] Waste cutting fluid from an auto parts processing factory, the waste fluid contains 5% oil, COD value 20000-35000mg / L, suspended solid 3000-6000mg / L, dissolved solid 5000-10000mg / L. The waste cutting fluid is treated by the system of the present invention.

[0042] S1: The viscous removal unit is a belt filter, the belt filter adopts a gravity belt filter, the filter cloth is made of ordinary non-woven fabric, the filter cloth precision is 10μm, and viscous and cuttings such as slick oil and paraffin can be removed effective retention. After the oily waste liquid enters the belt filter, it passes through the filter cloth under the action of gravity, the viscous matter is isolated and attached to the filter cloth, and the filtrate enters the liquid tank, and the removal efficiency of the viscous matter is >95%. The belt filter is equipped with a dirt collection box to collect the replaced filter cloth and the sticky matter attached. The belt filter monitors the filter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| iodine adsorption value | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com