Preparation method of polysubstituent 1,3,5-triazine

A multi-substitution and substituent technology is applied in the field of preparation of multi-substituted 1,3,5-triazines, which can solve the problems of environmentally unfriendly by-products and achieve the effects of reducing production costs, simple and practical operation, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

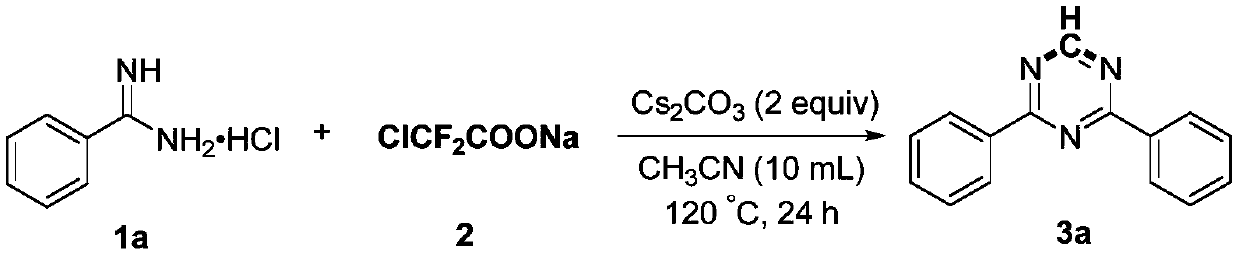

Embodiment 1

[0020]

[0021] Add 1a (4mmol), sodium difluorochloroacetate (4mmol), cesium carbonate (8mmol) and acetonitrile (10mL) into the reaction flask, then heat the reaction at 120°C for 24 hours. After the reaction was completed, it was first quenched with water, then extracted with ethyl acetate, and the organic phases were combined and dried with anhydrous sodium sulfate. After concentration, the product 3a was obtained by column chromatography with a mixed solvent of petroleum ether and ethyl acetate. The yield was 96%. Pale yellow solid, Mp: 74-75℃; 1 H NMR (600MHz, CDCl 3 ):δ9.26(s,1H),8.66-8.63(m,4H),7.63-7.59(m,2H),7.57-7.54(m,4H); 13 C NMR (150MHz, CDCl 3 ): δ171.3, 166.7, 135.5, 132.8, 128.9, 128.7.

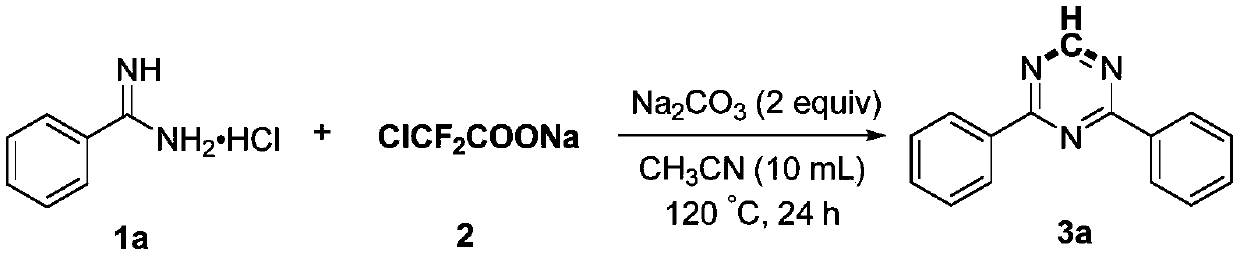

Embodiment 2

[0023]

[0024] Add 1a (4mmol), sodium difluorochloroacetate (4mmol), sodium carbonate (8mmol) and acetonitrile (10mL) into the reaction flask, then heat the reaction at 120°C for 24 hours. After the reaction was completed, it was first quenched with water, then extracted with ethyl acetate, and the organic phases were combined and dried with anhydrous sodium sulfate. After concentration, the product 3a was obtained by column chromatography with a mixed solvent of petroleum ether and ethyl acetate. The yield was 83%. Pale yellow solid, Mp: 74-75℃; 1 H NMR (600MHz, CDCl 3 ):δ9.26(s,1H),8.66-8.63(m,4H),7.63-7.59(m,2H),7.57-7.54(m,4H); 13 C NMR (150MHz, CDCl 3 ): δ171.3, 166.7, 135.5, 132.8, 128.9, 128.7.

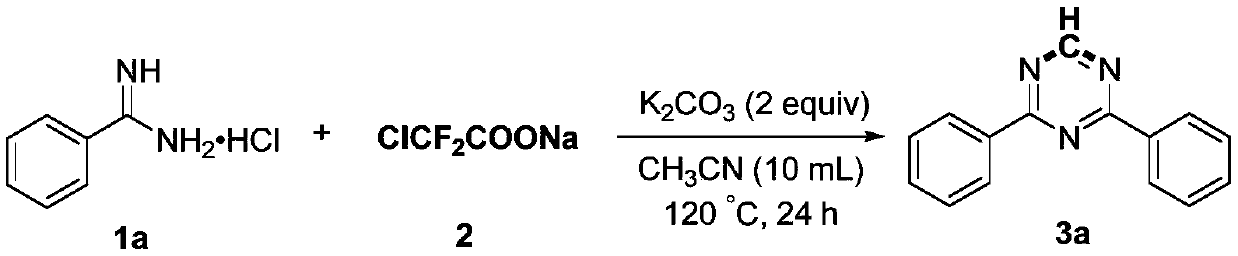

Embodiment 3

[0026]

[0027] Add 1a (4mmol), sodium difluorochloroacetate (4mmol), potassium carbonate (8mmol) and acetonitrile (10mL) into the reaction flask, then heat the reaction at 120°C for 24 hours. After the reaction was completed, it was first quenched with water, then extracted with ethyl acetate, and the organic phases were combined and dried with anhydrous sodium sulfate. After concentration, the product 3a was obtained by column chromatography with a mixed solvent of petroleum ether and ethyl acetate. The yield was 78%. Pale yellow solid, Mp: 74-75℃; 1 H NMR (600MHz, CDCl 3 ):δ9.26(s,1H),8.66-8.63(m,4H),7.63-7.59(m,2H),7.57-7.54(m,4H); 13 C NMR (150MHz, CDCl 3 ): δ171.3, 166.7, 135.5, 132.8, 128.9, 128.7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com