Modified polyester powder paint and preparation method thereof

A technology of modified polyester and powder coatings, applied in powder coatings, polyester coatings, coatings, etc., which can solve the problems of gas removal, poor degassing effect, and weak degassing effect, so as to reduce air bubbles and improve production efficiency. Membrane effect, effect of increasing compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

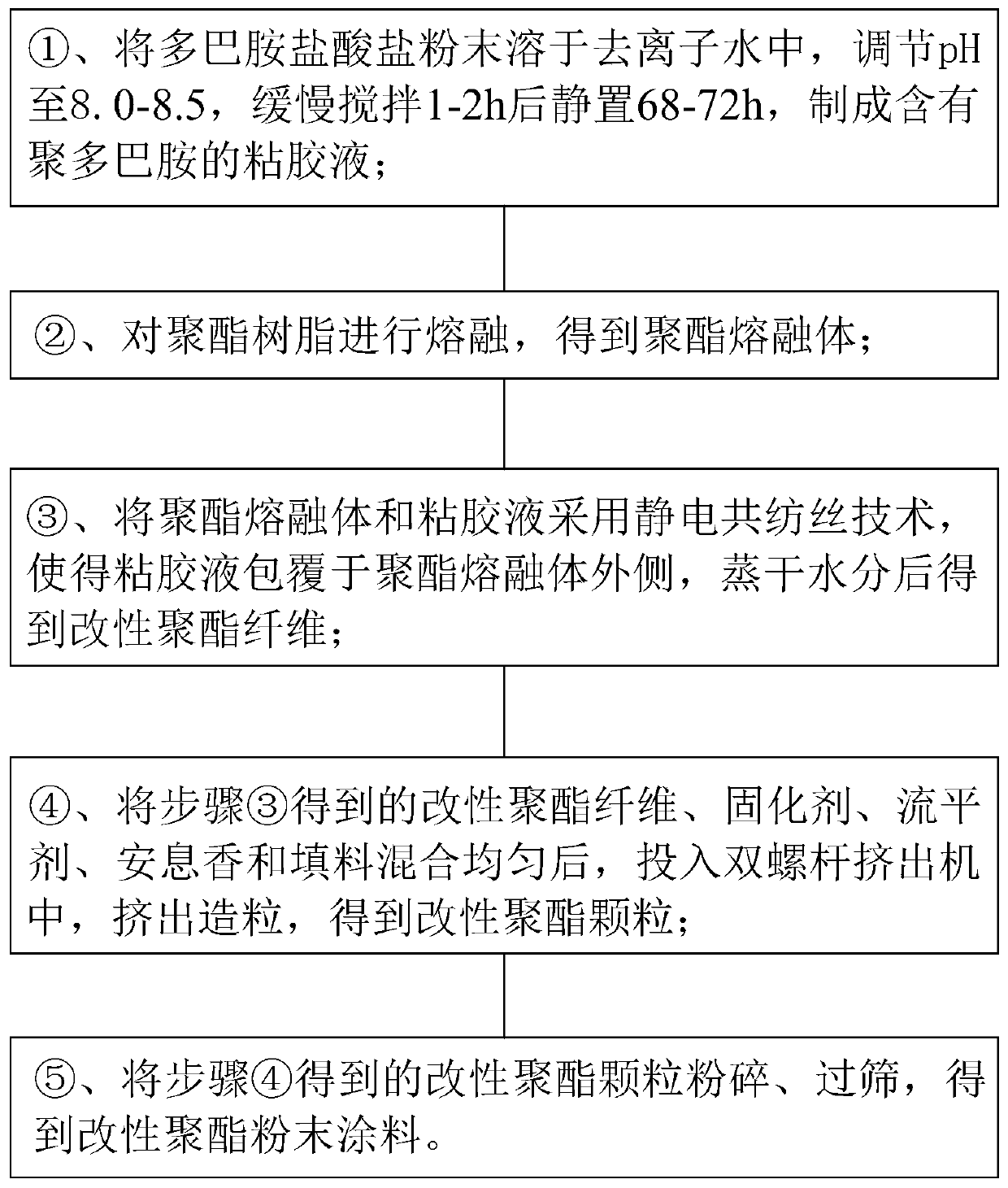

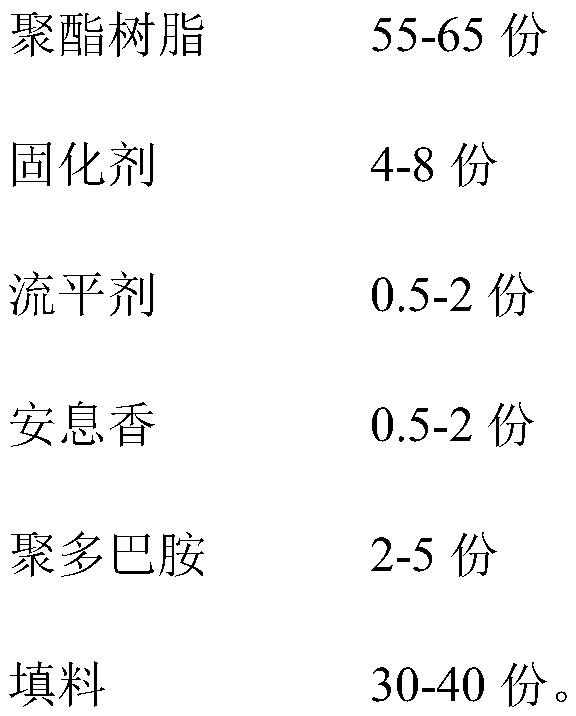

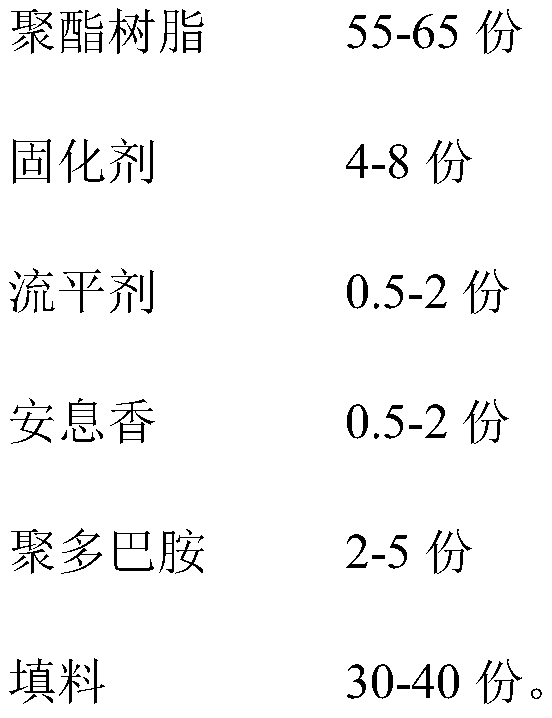

[0042] A preparation method of modified polyester powder coating, comprising the following steps:

[0043] ①. Dissolve 2kg of dopamine hydrochloride powder in 2kg of deionized water, adjust the pH of the solution to 8.0 with 1M Tris buffer, and slowly stir for 2 hours at a stirring speed of 30r / min. Stand still for 68h to make viscose liquid containing polydopamine;

[0044] 2. Take by weighing 55kg of PBT and melt to obtain a polyester melt;

[0045] ③. Electrostatic co-spinning technology is used to coat the polyester melt and viscose liquid, so that the viscose liquid is coated on the outside of the polyester melt, and dried at a temperature of 80°C for 30 minutes, so that the water is evaporated to dryness to obtain a modified polyester fiber;

[0046] ④. Mix the modified polyester fiber obtained in step ③, 2kg of TGIC, 2kg of T105M, 1kg of GLP505, 2kg of benzoin, 30kg of nano-calcium carbonate and 0.5kg of color masterbatch, and then put them into the twin-screw extrude...

Embodiment 2- Embodiment 8

[0049] Embodiment 2-Embodiment 8 are all based on the method of Embodiment 1, the components and the content of the components are adjusted, and the specific adjustment parameters are shown in Table 1 below.

[0050] Raw materials and preparation parameters of the modified polyester powder coating of table 1 embodiment 1-embodiment 8

[0051]

[0052]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com