Poly-silicon resin as well as preparation method and application thereof

A resin and polysilicon technology, applied in the field of silicone sealant primer and its preparation, can solve the problems of poor water resistance and adhesion of the sealant, and achieve the effect of improving adhesion and excellent applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

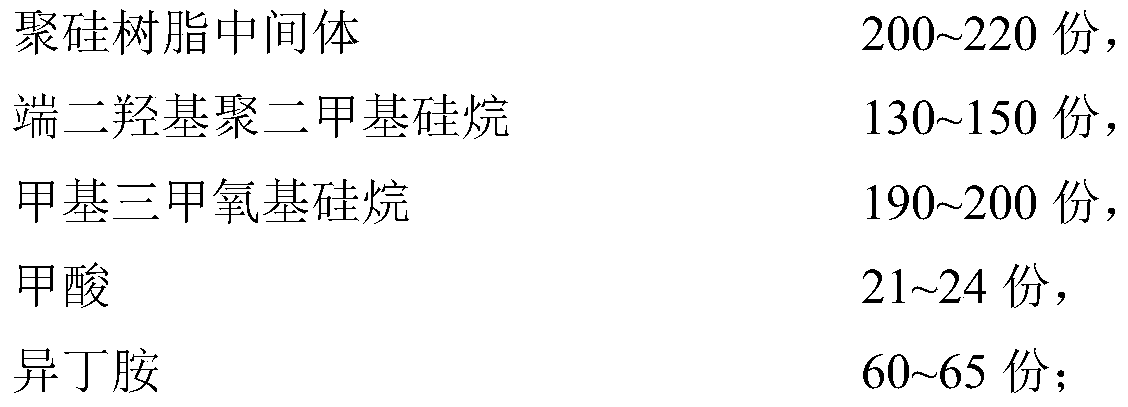

[0042] A silicone sealant primer, consisting of the following raw materials in parts by weight:

[0043]

[0044] The preparation method of described polysilicone resin is as follows:

[0045] 1) Stir 220 parts of methyltriisopropylsilane and 150 parts of toluene for 30 minutes, add 108 parts of hydrochloric acid with a mass fraction of 1% dropwise, continue stirring for 40 minutes, let stand, separate the acidic water layer, wash with water until neutral, and then Toluene was distilled off under reduced pressure to obtain a polysilicone resin intermediate with an average molar mass of 12000 and a Si-OH group mass fraction of 1.2%;

[0046] 2) Mix 210 parts of polysilicone resin intermediate, 140 parts of dihydroxypolydimethylsilane with a viscosity of 20 mPa·s at 25°C, and 190 parts of methyltrimethoxysilane, heat to 55°C, stir for 60 minutes, and cool to room temperature;

[0047] 3) Add 60 parts of isobutylamine and 24 parts of formic acid, stir and heat to 75°C, react...

Embodiment 2

[0052] A silicone sealant primer, which is basically the same as in Example 1, the only difference is that the coupling agent is replaced by 5 parts of 1,3,5-tris(trimethoxysilylpropyl) polyisocyanate.

Embodiment 3

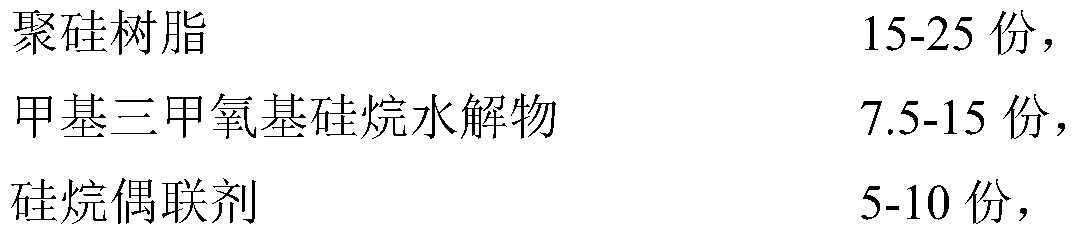

[0054] A silicone sealant primer is basically the same as Example 1, the only difference being that the silicone sealant primer consists of the following raw materials in parts by weight:

[0055]

[0056]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com