Inorganic treatment agent, and method for carrying out aluminum alloy modification treatment by utilizing inorganic treatment agent

A treatment agent and an inorganic technology, which is applied in the field of aluminum alloy modifiers, can solve the problems of difficult control of the preparation process, inability to modify the modification at the same time, and poor effect of the modification agent, so as to improve the efficiency of modification treatment, save the step of slag removal, and fine particles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

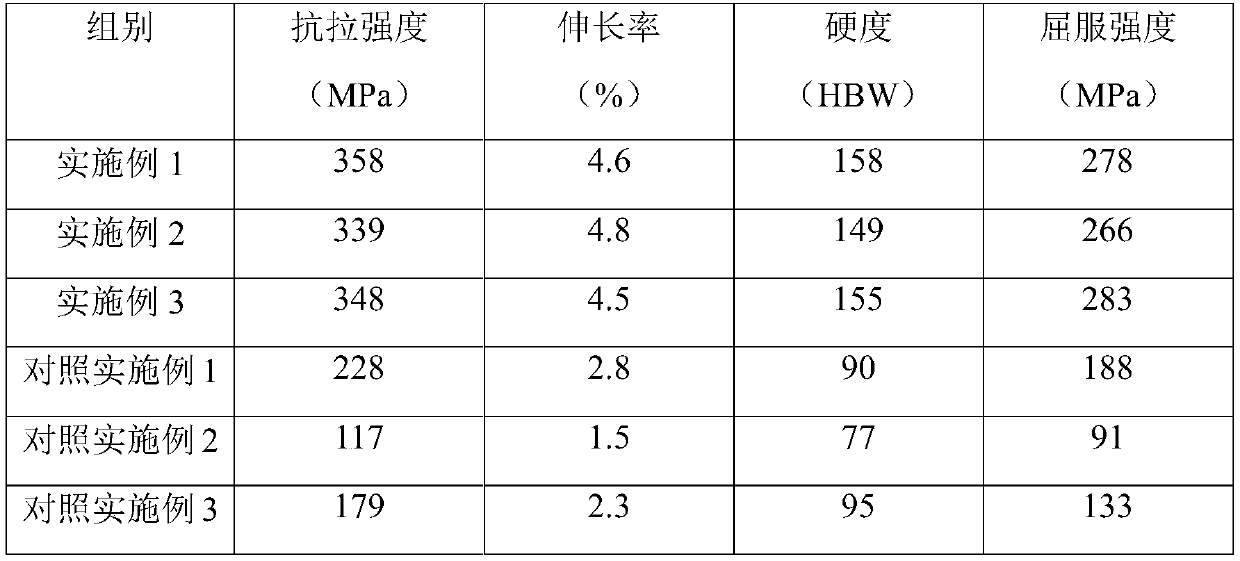

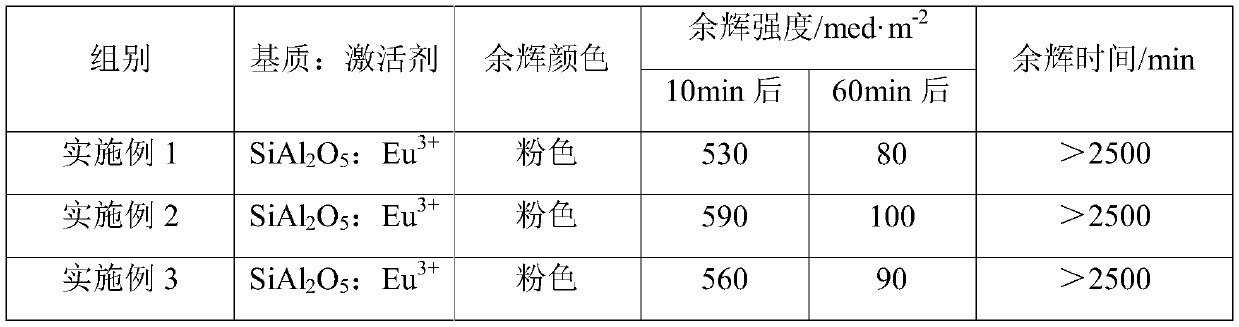

Examples

Embodiment 1

[0033] Embodiment 1: prepare inorganic treatment agent as follows:

[0034] 1. Preparation of raw materials:

[0035] Sodium oxalate, manganese nitrate, manganese acetate, potassium fluoroaluminate, potassium chloride, sodium chloride, silicon carbide, aluminum oxide, sodium molybdate, europium nitrate, and copper oxide do not contain crystal water and have a purity greater than 99.9 wt%. The particle size is 150 mesh;

[0036] Bentonite is calcium-based bentonite, the composition is: Al 2 o 3 13.24wt%, H 2 O is 4.56wt%, Fe 2 o 3 0.34wt%, MgO 2.22wt%, CaO 1.14wt%, TiO 2 0.09wt%, FeO 0.07wt%, MnO≤0.08wt%, P 2 o 3 0.03wt%, K 2 O+Na 2 O is 0.56wt%, the balance is SiO 2 , the particle size of the bentonite powder is 100 mesh;

[0037] The inert gas is helium or nitrogen.

[0038] The composition of the eutectic aluminum-silicon alloy is Si 17.0%, Fe 0.01%, Ti 0.22%, Mg 0.2%, Cu 4.8%, Mn 0.1%, Zn≤0.03%, Ca≤0.02%, and the balance is Al;

[0039] The lubricant is MoS ...

Embodiment 2

[0051] Embodiment 2: prepare inorganic treatment agent as follows:

[0052] Second, the preparation of raw materials:

[0053] Sodium oxalate, manganese nitrate, manganese acetate, potassium fluoroaluminate, potassium chloride, sodium chloride, silicon carbide, aluminum oxide, sodium molybdate, europium nitrate, and copper oxide do not contain crystal water and have a purity greater than 99.9 wt%. The particle size is 250 mesh;

[0054] Bentonite is calcium-based bentonite or sodium-based bentonite, and its composition is: Al 2 o 3 16.88wt%, H 2 O is 8.23wt%, Fe 2 o 3 1.22wt%, MgO is 4.35wt%, CaO is 2.09wt%, TiO 2 0.22wt%, FeO 0.58wt%, MnO≤0.08wt%, P 2 o 3 0.11wt%, K 2 O+Na 2 O is 1.39wt%, the balance is SiO 2 , the particle size of the bentonite powder is 150 mesh;

[0055] The inert gas is helium or nitrogen.

[0056] The composition of the eutectic aluminum-silicon alloy is Si 18.5%, Fe 0.05%, Ti 0.34%, Mg 0.5%, Cu 5.5%, Mn 0.4%, Zn≤0.03%, Ca≤0.02%, and the ba...

Embodiment 3

[0069] Embodiment 3: prepare inorganic treatment agent as follows:

[0070] 3. Preparation of raw materials:

[0071] Sodium oxalate, manganese nitrate, manganese acetate, potassium fluoroaluminate, potassium chloride, sodium chloride, silicon carbide, aluminum oxide, sodium molybdate, europium nitrate, and copper oxide do not contain crystal water and have a purity greater than 99.9 wt%. The particle size is 200 mesh;

[0072] Bentonite is calcium-based bentonite or sodium-based bentonite, and its composition is: Al 2 o 3 14.89wt%, H 2 O is 6.45wt%, Fe 2 o 3 0.79wt%, MgO 3.01wt%, CaO 1.78wt%, TiO 2 0.14wt%, FeO 0.31wt%, MnO≤0.08wt%, P 2 o 3 0.07wt%, K 2 O+Na 2 O is 0.82wt%, the balance is SiO 2 , The particle size of the bentonite powder is 125 mesh.

[0073] The composition of the eutectic aluminum-silicon alloy is Si 17.8%, Fe 0.03%, Ti 0.28%, Mg 0.35%, Cu 5.1%, Mn 0.25%, Zn≤0.03%, Ca≤0.02%, and the balance is Al;

[0074] The lubricant is MoS 2 Mixture of po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com