Ultra-lubricating solid thin film with space environment adaptabilit

A space environment, super-lubricating technology, applied in the direction of vacuum evaporation plating, ion implantation plating, metal material coating technology, etc., can solve the problems such as the large gap between the life of the film and the space application requirements, and the breakage of the C-H bond. The effect of improving energy utilization efficiency, prolonging service life, and reducing exhaust emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

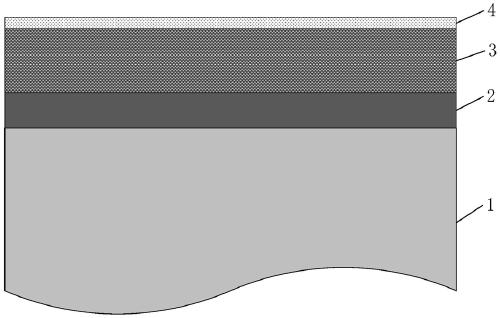

[0028] Such as figure 1 As shown, a super-lubricant solid film with adaptability to the space environment is composed of a hydrogen diffusion prevention layer 2, a hydrogen storage intermediate layer 3, and a super-lubricating functional layer 4 sequentially attached to a substrate 1, wherein the substrate 1 Stainless steel 9Cr18, hydrogen diffusion prevention layer 2 is TiN, hydrogen storage intermediate layer 3 is TiH x , The super-lubricating functional layer 4 is a-C:H.

[0029] The thin film is prepared by reactive magnetron sputtering technology: the background vacuum of the vacuum chamber during the deposition process is less than or equal to 1×10 -3 Pa, the total deposition time is 1.5 hours.

[0030] (1) Preparation of hydrogen diffusion prevention layer 2: Ti target with purity higher than 99.99% is used as the target material, and high-purity nitrogen with purity greater than or equal to 99.999% is used as the reaction gas. Other parameters are selected by conventional t...

Embodiment 2

[0035] A super-lubricant solid film with space environment adaptability, the film is composed of a hydrogen diffusion prevention layer 2, a hydrogen storage intermediate layer 3, and a super-lubricating functional layer 4 which are sequentially attached to a substrate 1, wherein the substrate 1 is a bearing steel GCr15, hydrogen diffusion prevention layer 2 is ZrN, hydrogen storage intermediate layer 3 is TiFeH x , The super-lubricating functional layer 4 is a-C:H.

[0036] The thin film is prepared by reactive magnetron sputtering technology: the target material uses a Zr target with a purity higher than 99.99% and a Ti-Fe alloy target with a purity greater than or equal to 99.99% (mass ratio 50:50), and the purity of the reactive gas is better than 99.999 % High-purity hydrogen and acetylene gas with a purity better than 99.9%.

[0037] The thin film is prepared by reactive magnetron sputtering technology: the background vacuum of the vacuum chamber during the deposition process ...

Embodiment 3

[0043] A super-lubricating solid film with adaptability to space environment. The film is composed of a hydrogen diffusion prevention layer 2, a hydrogen storage intermediate layer 3 and a super-lubricating functional layer 4 which are sequentially attached to a substrate 1, wherein the substrate 1 is a titanium alloy Ti6Al4V, hydrogen diffusion prevention layer 2 is Al 2 O 3 , The hydrogen storage intermediate layer 3 is Ti 2 NiH x , The super-lubricating functional layer 4 is a-C:H.

[0044] The thin film is prepared by reactive magnetron sputtering technology: the background vacuum of the vacuum chamber during the deposition process is less than or equal to 1×10 -3 Pa, the total deposition time is 1.5 hours.

[0045] (1) Preparation of hydrogen diffusion prevention layer 2: Al target with purity greater than or equal to 99.99% is used as the target material, oxygen with purity greater than or equal to 99.99% is used as the reaction gas, other parameters are selected by convention...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com