A kind of blasting excavation method of hard rock tunnel

A tunnel and hard rock technology, applied in the field of hard rock tunnel blasting and excavation, can solve the problems of low efficiency and difficult tunnel construction, and achieve the effects of reducing harmful gases, purifying the construction environment, and prolonging the tangential effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment provides a method for excavating a hard rock tunnel by blasting, comprising the following steps:

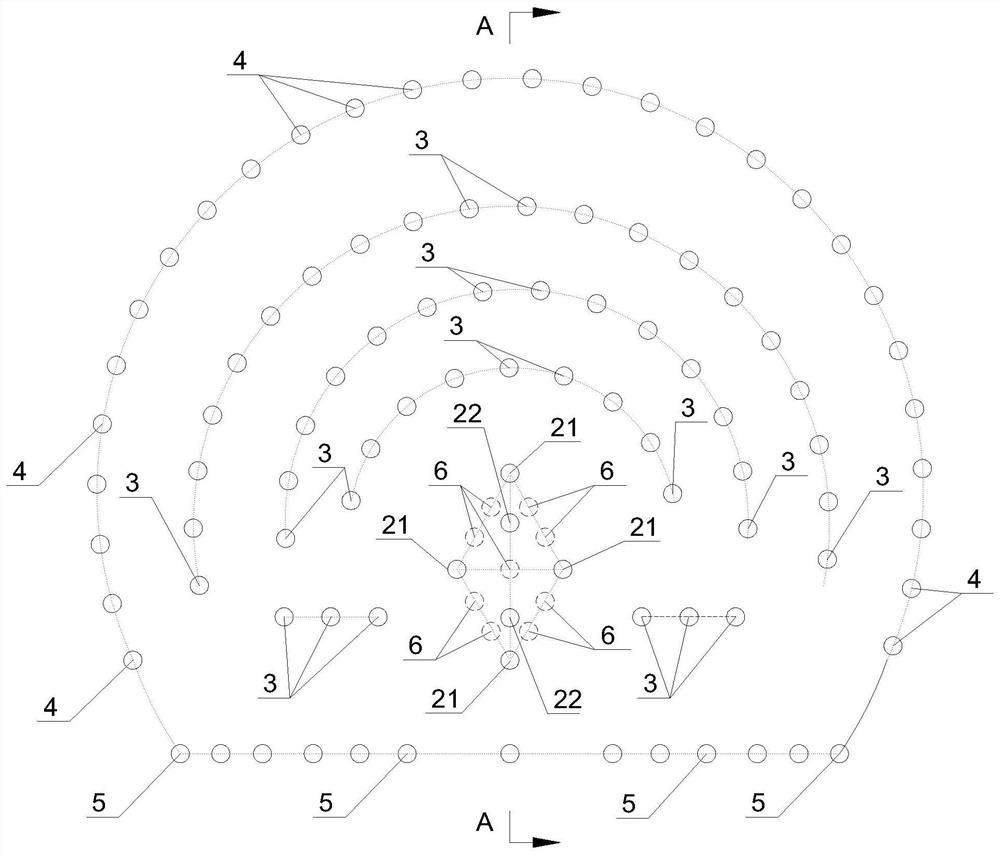

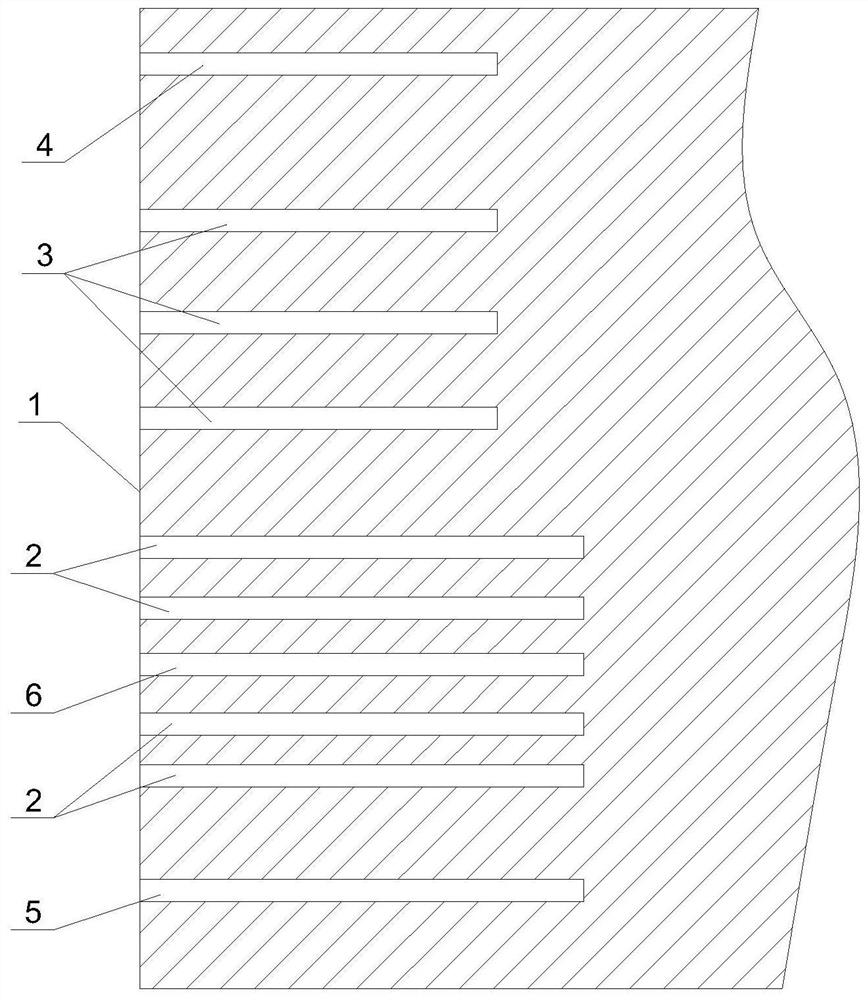

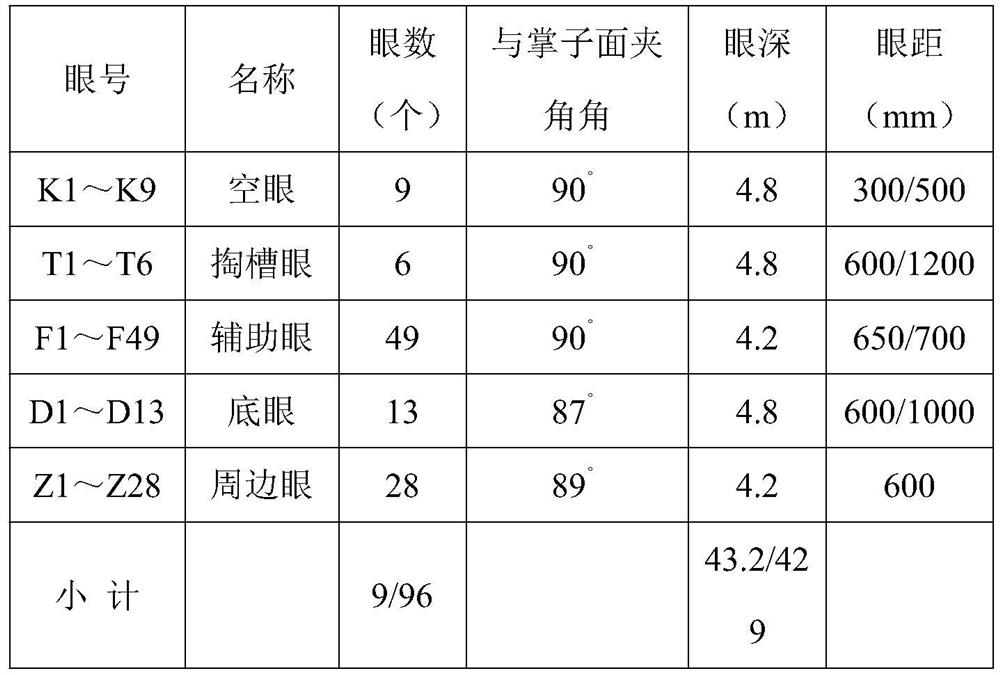

[0042] Step 1: Surveyors use red paint to draw the contour lines of the 4th peripheral eye and the 2nd cutting hole on the rock of the face 1; move the excavation trolley to the face 1 of the ballasted and leveled site, Hand-held pneumatic rock drills, 3m and 5m long drill rods with drill bits are placed on the two platforms of the working surface 1 and the trolley as required, and the wind and water pipelines are connected; according to the schematic diagram of the blast hole layout, as shown in figure 1 As shown, the fixed area, the fixed personnel, and the fixed number of holes are drilled. The auxiliary eye 3 is set outside the cut hole 2, the peripheral eye 4 is set outside the auxiliary eye 3, and the bottom eye 5 is set on the cut hole 2, the auxiliary eye 3 and the surrounding area. Below the eye 4, the positions of the auxiliary eye 3 and the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com