Method and device for preparing copper indium gallium selenide thin film battery

A thin film battery, copper indium gallium selenide technology, applied in circuits, electrical components, final product manufacturing, etc., can solve the problem that CIGS films cannot have high-quality band gaps at the same time, the ratio of four elements is prone to fluctuations, and the conversion of selenium elements It can solve the problem of high rate and high concentration, and achieve the effect of solving the difficulty of concentration debugging, improving the utilization rate and improving the uniformity of film formation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

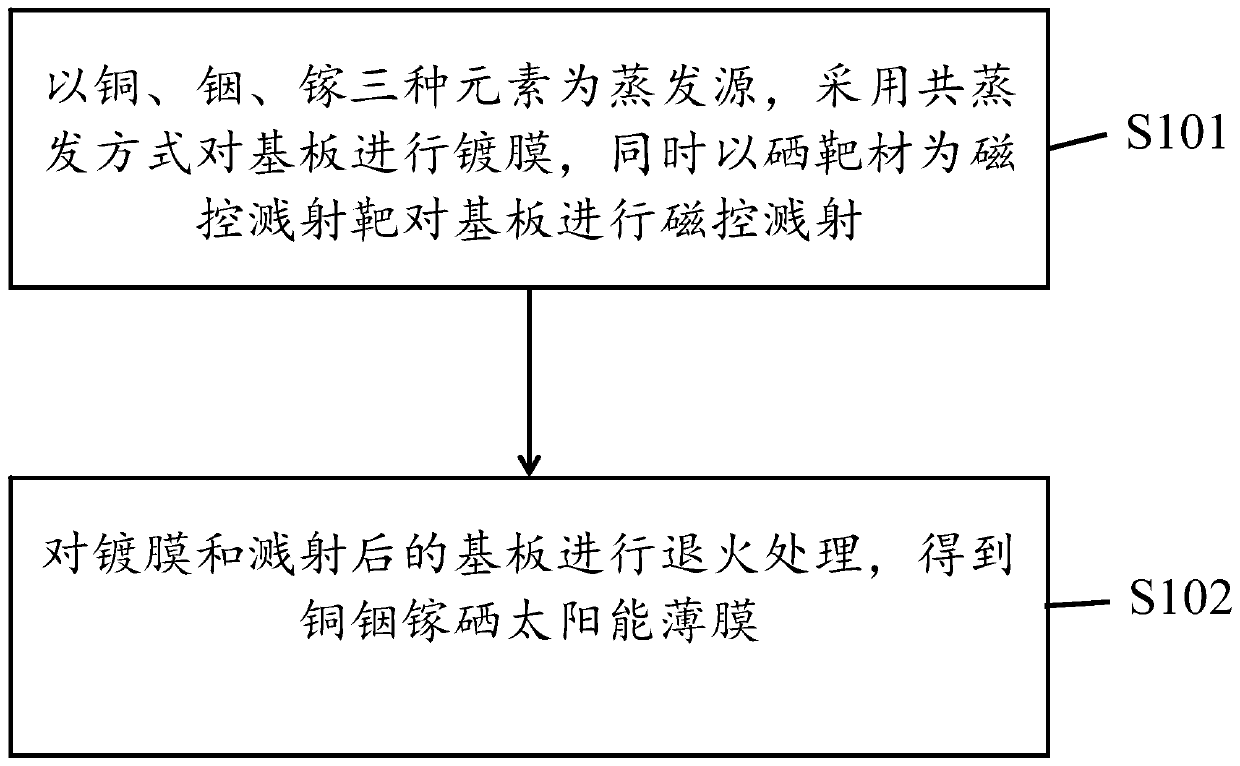

[0059] This embodiment provides a method for preparing a copper indium gallium selenide solar thin film, specifically as follows:

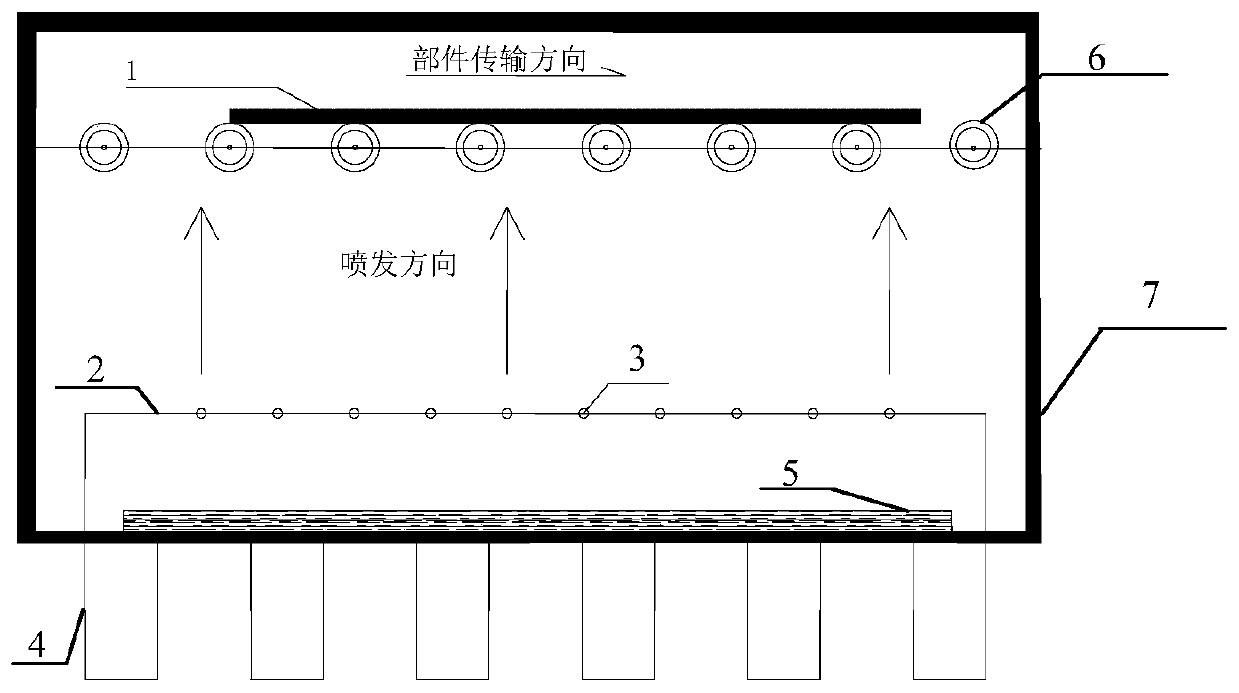

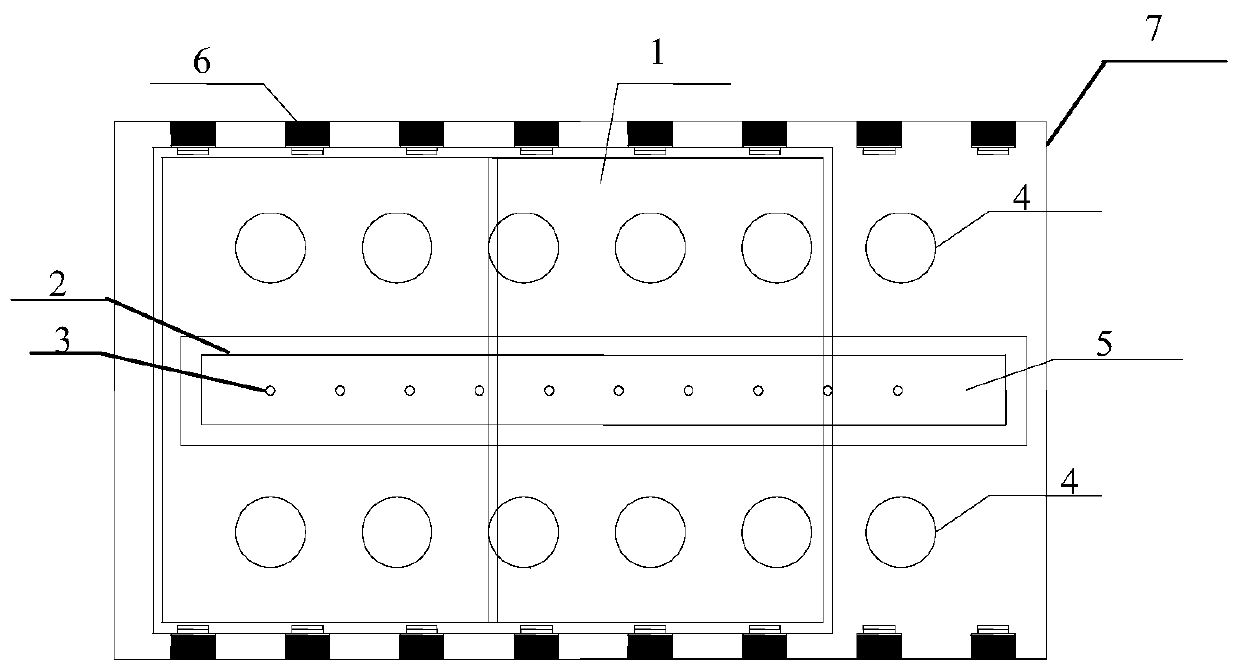

[0060] In the CIGS coating chamber, soda-lime glass is used as the substrate, and it is installed on the transmission device. The transmission device is set above the chamber, and a heating source is installed above the glass substrate. Arrange gallium evaporation source, indium evaporation source, copper evaporation source, copper evaporation source, gallium evaporation source, indium evaporation source from left to right. Set at the bottom of the chamber and on both sides of the sputtering device, the heating power of the gallium evaporation source is 900w, the heating power of the copper evaporation source is 2500w, the heating power of the indium evaporation source is 900w, and the deposition rate of gallium is 2A / S; The deposition rate of elements is 3A / S; the deposition rate of indium is 2A / S; the selenium target is set in the middle of the ...

Embodiment 2

[0062] This embodiment provides a method for preparing a copper indium gallium selenide solar thin film, specifically as follows:

[0063] In the CIGS coating chamber, quartz glass is used as the substrate and installed on the transmission device. The transmission device is set above the chamber, and the heating source is set above the glass substrate. The temperature is 600 ° C. Gallium evaporation source, indium evaporation source, copper evaporation source, copper evaporation source, gallium evaporation source, indium evaporation source, gallium evaporation source, indium evaporation source are arranged in order from left to right. The distance between the evaporation sources is 50cm, and the distance from the substrate The evaporation source is set at the bottom of the chamber and on both sides of the sputtering device. The heating power of the gallium evaporation source is 1000w, the heating power of the copper evaporation source is 3000w, and the heating power of the indi...

Embodiment 3

[0065] This embodiment provides a method for preparing a copper indium gallium selenide solar thin film, specifically as follows:

[0066] In the CIGS coating chamber, borosilicate glass is used as the substrate and installed on the transmission device. The transmission device is set above the chamber, and the heating source is set above the glass substrate. The temperature is 600 ° C. The transmission device starts to drive at a speed of 15cm / min. The chamber is arranged in turn from left to right with gallium evaporation source, indium evaporation source, copper evaporation source, copper evaporation source, gallium evaporation source, indium evaporation source, the distance between the evaporation sources is 40cm, and the distance from the substrate is 1.4m. The sources are respectively set at the bottom of the chamber and on both sides of the sputtering device. The heating power of the gallium evaporation source is 800w, the heating power of the copper evaporation source is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com