Waste sulfuric acid recycling system and method

A regeneration system and sulfuric acid technology, which is applied in the field of waste sulfuric acid recovery and waste sulfuric acid recovery and regeneration system, can solve the problems affecting the removal efficiency of NF membrane metal impurities and the complexity of sulfuric acid components, so as to avoid secondary pollution, low cost and improve removal rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

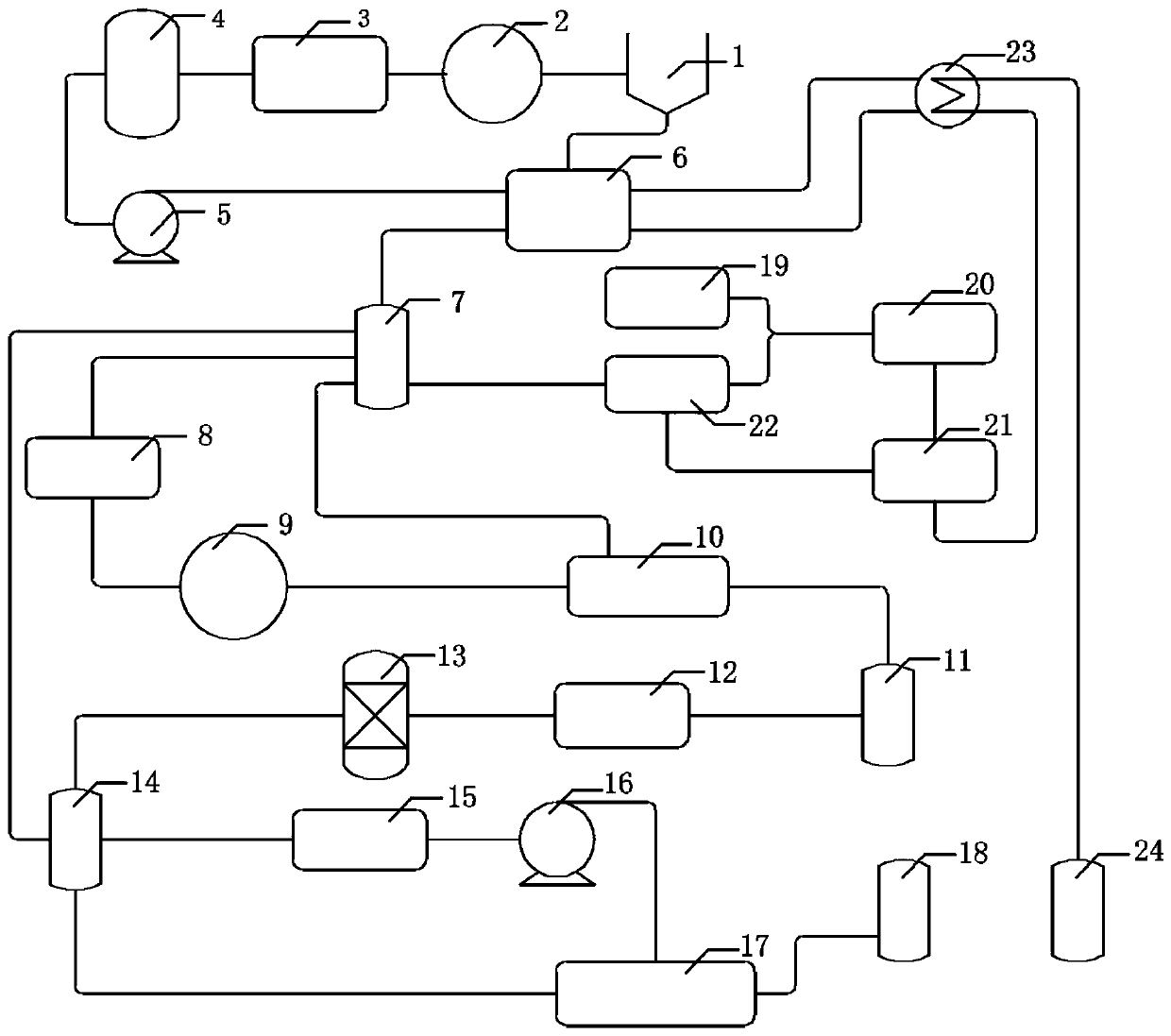

[0036] Waste and old sulfuric acid recovery regeneration system of the present invention such as figure 1 As shown, including: multi-stage sedimentation tank 1, acid-resistant pump I2, plate and frame filter press equipment 3, acid storage tank 4, MF circulation pump 5, MF membrane equipment 6, UF circulation tank 7, bag filter I8, acid-resistant pump II9, UF membrane equipment 10, UF acid storage tank 11, acid distribution equipment I12, oxidation treatment tank 13, NF circulation tank 14, bag filter II15, NF circulation pump 16, acid-resistant NF membrane equipment 17, finished acid storage tank 18 , industrial sulfuric acid tank 19, acid distribution equipment II20, distillation equipment 21, settling equipment 22, heat exchanger 23 and reagent sulfuric acid storage tank 24;

[0037] The multi-stage sedimentation tank 1 is connected with the acid-resistant pump 12, the plate and frame filter press equipment 3, the acid storage tank 4, the MF circulation pump 5, and the MF m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com