High-boron glass sea set handle welding device

A high boron glass and welding device technology, applied in glass production, glass molding, glass re-molding and other directions, can solve problems such as production capacity, low yield, bursting, etc., to improve product qualification rate, reduce stress, suffer uniform force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

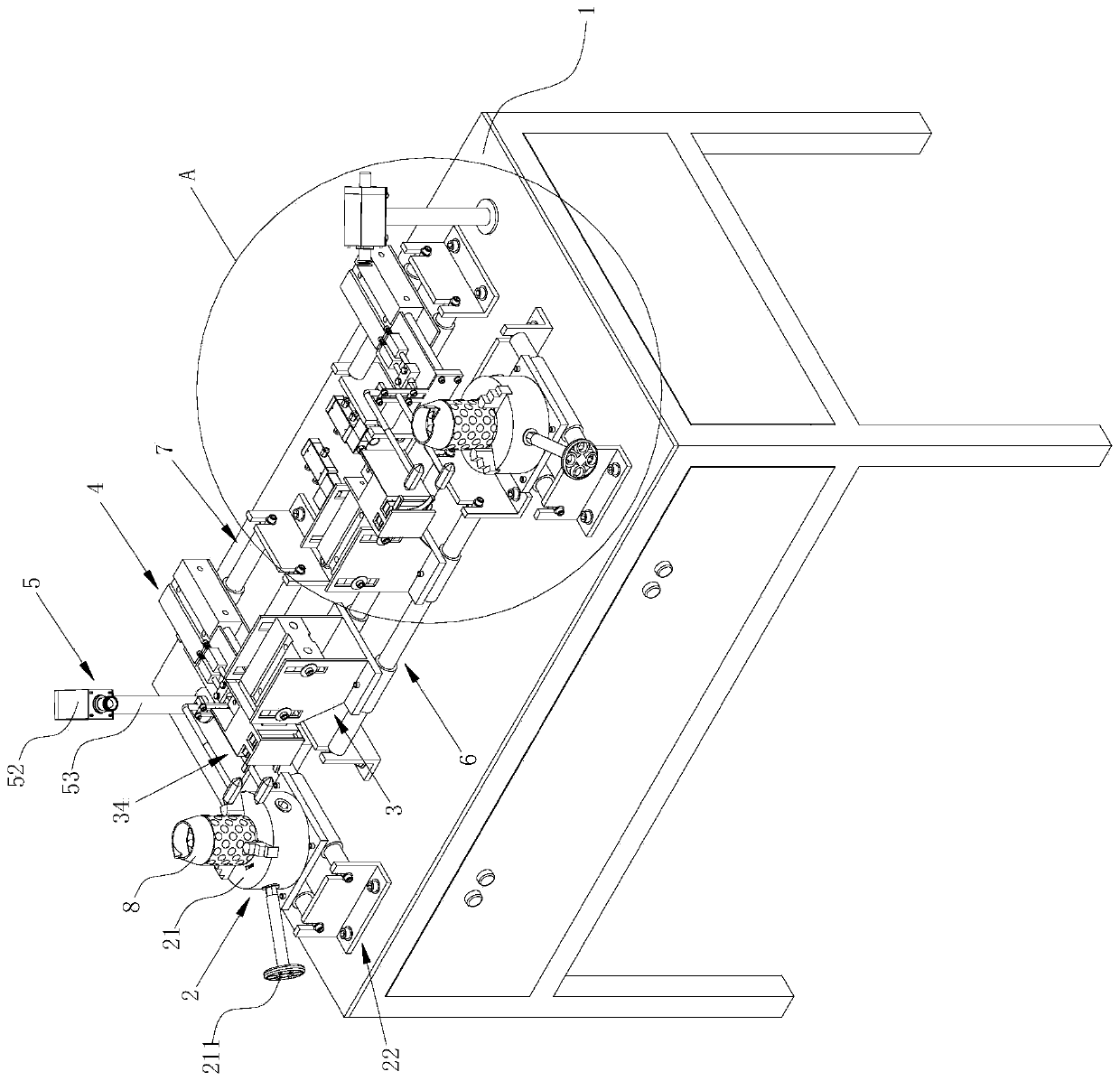

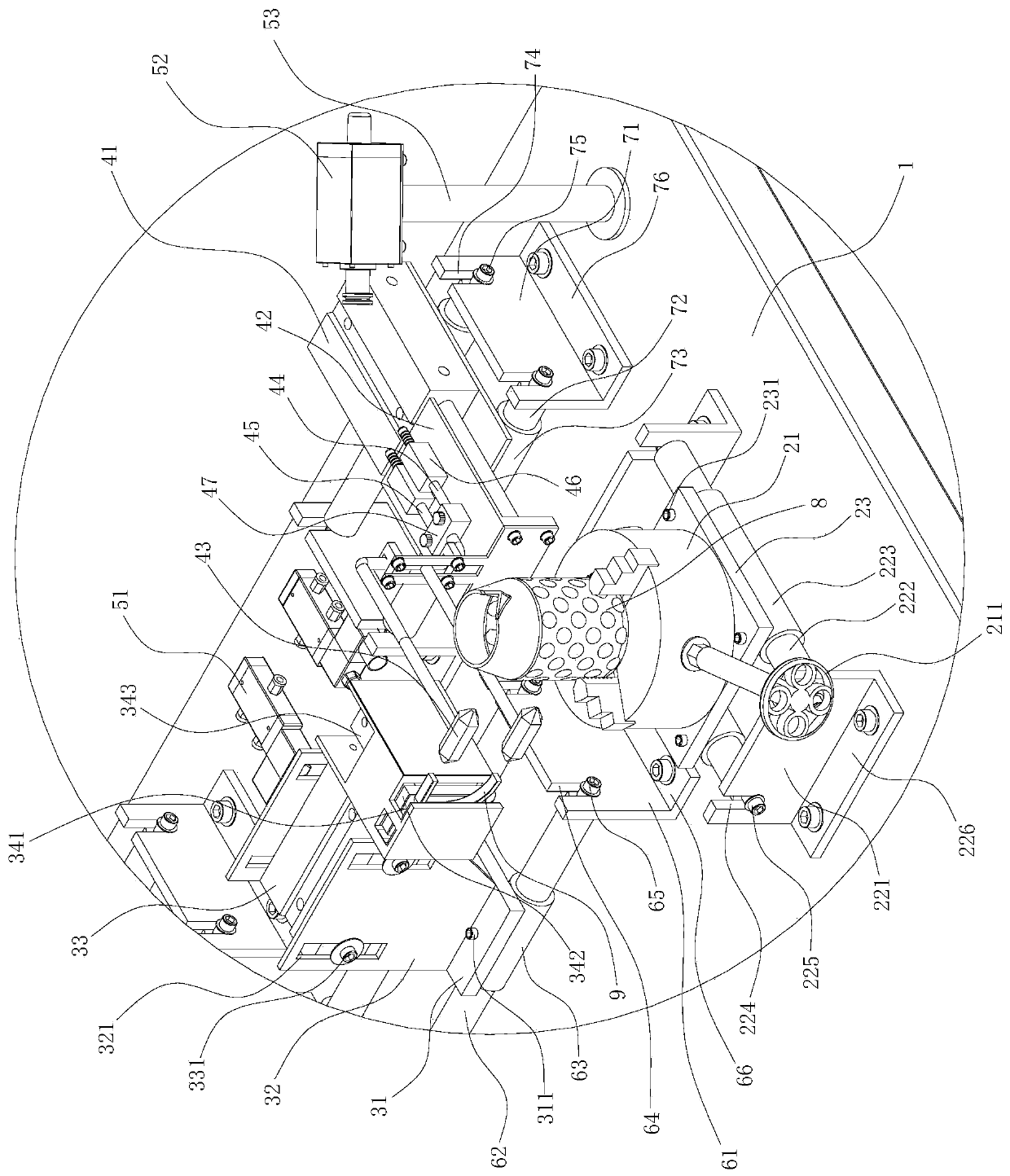

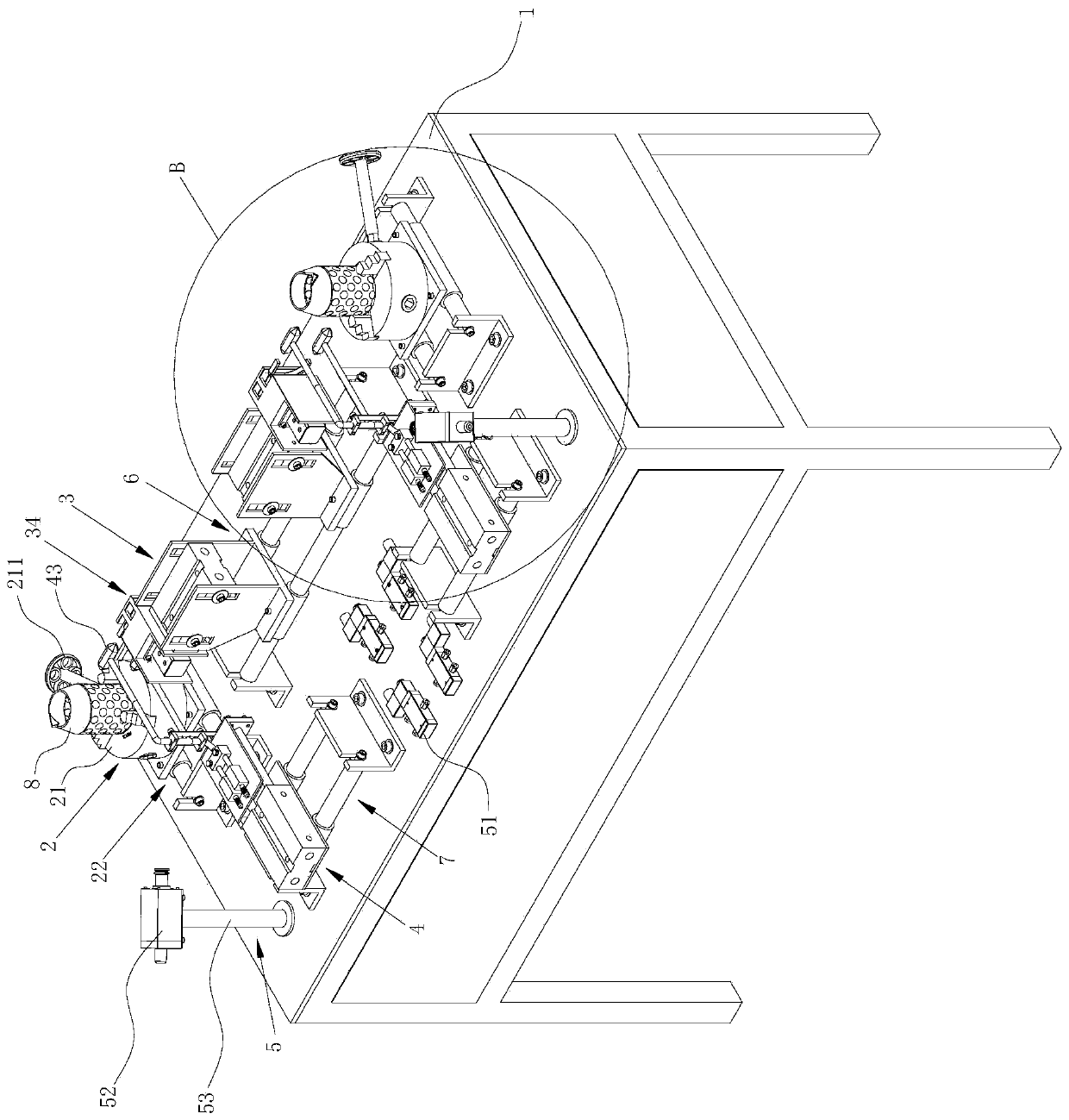

[0032] see Figure 1-Figure 6 , a high boron glass tea set handle welding device, including a rectangular horizontal workbench 1 and two chuck assemblies 2 installed on the workbench 1, two handle clamping assemblies 3, two heating assemblies 4 and an electric control assembly .

[0033] The length direction of the workbench 1 is left-right direction, and the side close to the middle of the workbench 1 in the longitudinal direction along the left-right direction of the workbench 1 is the inside, and the side away from the middle of the workbench 1 in the length direction is the outside.

[0034] The two chuck assemblies 2 are located at the front of the workbench 1 near the two ends in the length direction of the horizontal workbench 1, and the two chuck assemblies 2 are arranged symmetrically along the center line of the workbench 1 in the length direction. A chuck assembly 2 includes a chuck 21 and a first base 22, the first base 22 includes two vertically arranged first su...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap