Application of a copper-doped aluminum phosphate molecular sieve catalyst synthesized by ionothermal method in the synthesis of 5-hydroxymethylfurfural

A technology of aluminum phosphate molecular sieve and hydroxymethylfurfural, applied in molecular sieve catalysts, physical/chemical process catalysts, organic chemistry, etc., can solve problems such as increasing the difficulty of product separation, reducing catalyst stability, and limiting industrial applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

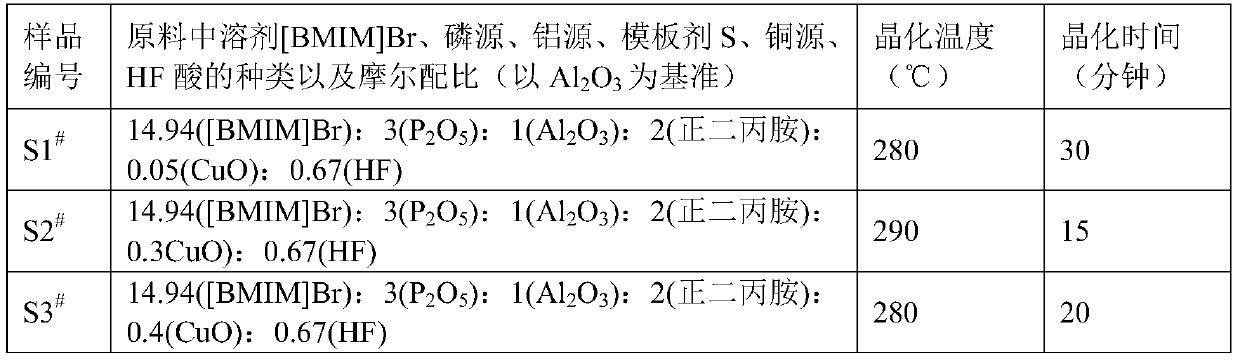

[0067] Example 1: Sample S1 # preparation of

[0068] Place the two-necked round-bottomed flask in a 90°C oil bath, and add 40.0g [BMIM]Br, 7.2g phosphoric acid, 5.0g aluminum isopropoxide, 2.5g n-dipropylamine, 0.12g copper acetate and 0.16g hydrofluoric acid. After stirring evenly, quickly transfer the mixture to a muffle furnace at 280°C, take it out after crystallization for 30 minutes, cool to room temperature, filter, wash with deionized water, dry at 100°C for 2 hours, and roast at 550°C for 7 hours to prepare Obtain the copper-doped aluminum phosphate molecular sieve, denoted as S1 # .

Embodiment 2

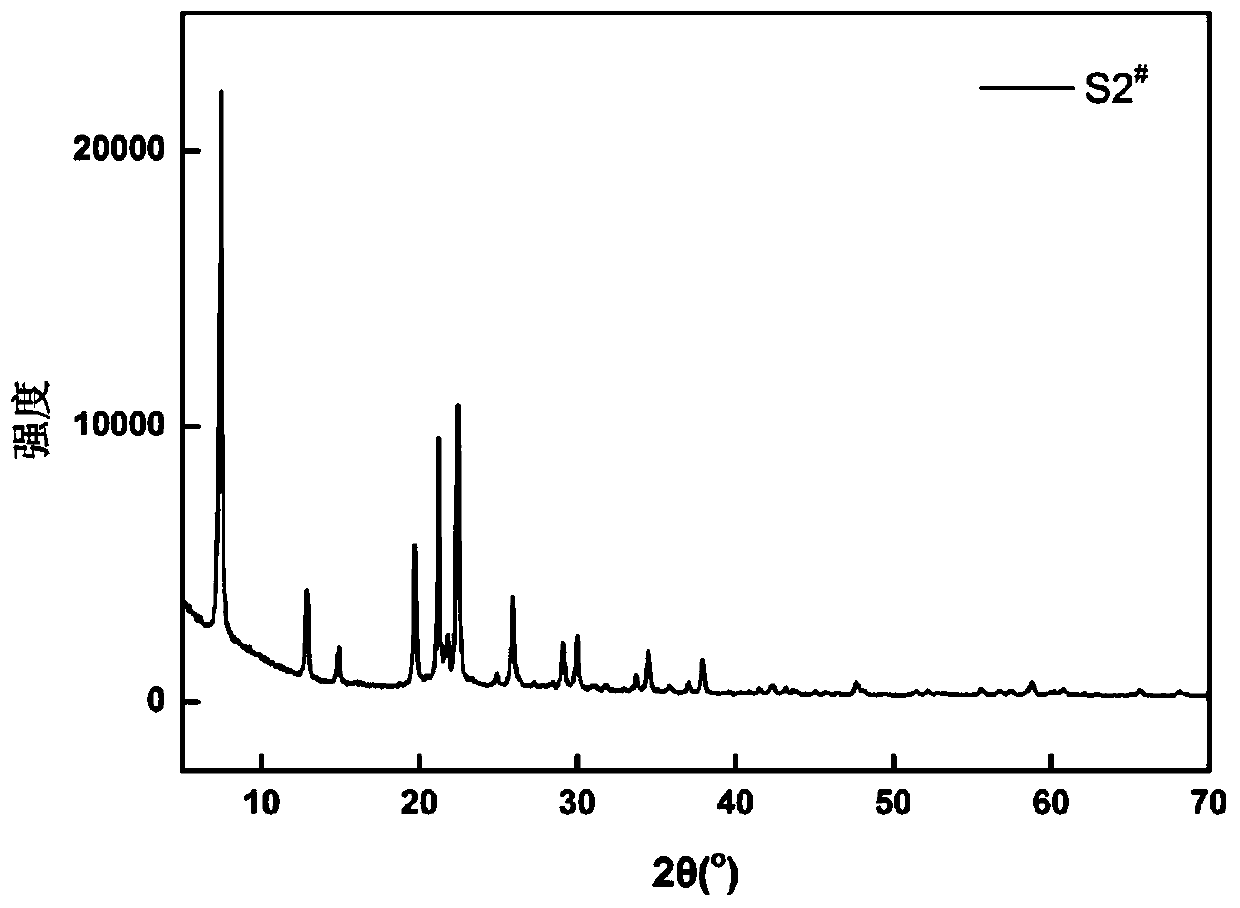

[0069] Example 2: Sample S2 # preparation of

[0070] Place the two-necked round-bottomed flask in a 90°C oil bath, and add 40.0g [BMIM]Br, 7.2g phosphoric acid, 5.0g aluminum isopropoxide, 2.5g n-dipropylamine, 0.72g copper acetate and 0.16g hydrofluoric acid. After stirring evenly, quickly transfer the mixed solution to a muffle furnace at 290°C, take it out after crystallization for 15 minutes, cool to room temperature, filter, wash with deionized water, dry at 110°C for 2 hours, and roast at 550°C for 7 hours to prepare Obtain the copper-doped aluminum phosphate molecular sieve, denoted as S2 # .

Embodiment 3

[0071] Example 3: Sample S3 # preparation of

[0072] Place the two-necked round-bottomed flask in an 80°C oil bath, and add 40.0g of [BMIM]Br, 7.2g of phosphoric acid, 5.0g of aluminum isopropoxide, 2.5g of n-dipropylamine, 0.96g of copper acetate and 0.16g of hydrofluoric acid. After stirring evenly, quickly transfer the mixture to a muffle furnace at 280°C, take it out after crystallization for 45 minutes, cool to room temperature, filter, wash with deionized water, dry at 120°C for 2 hours, and roast at 500°C for 7 hours to obtain The copper-doped aluminum phosphate molecular sieve, denoted as S3 # .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com