Preparation method of dibutyltin dilaurate

A technology of dibutyltin laurate and dibutyltin dichloride, which is applied in the direction of tin organic compounds, can solve the problems of toxic dust, high processing cost, waste of energy, etc., and achieve easy handling, high salt content, and low energy consumption consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

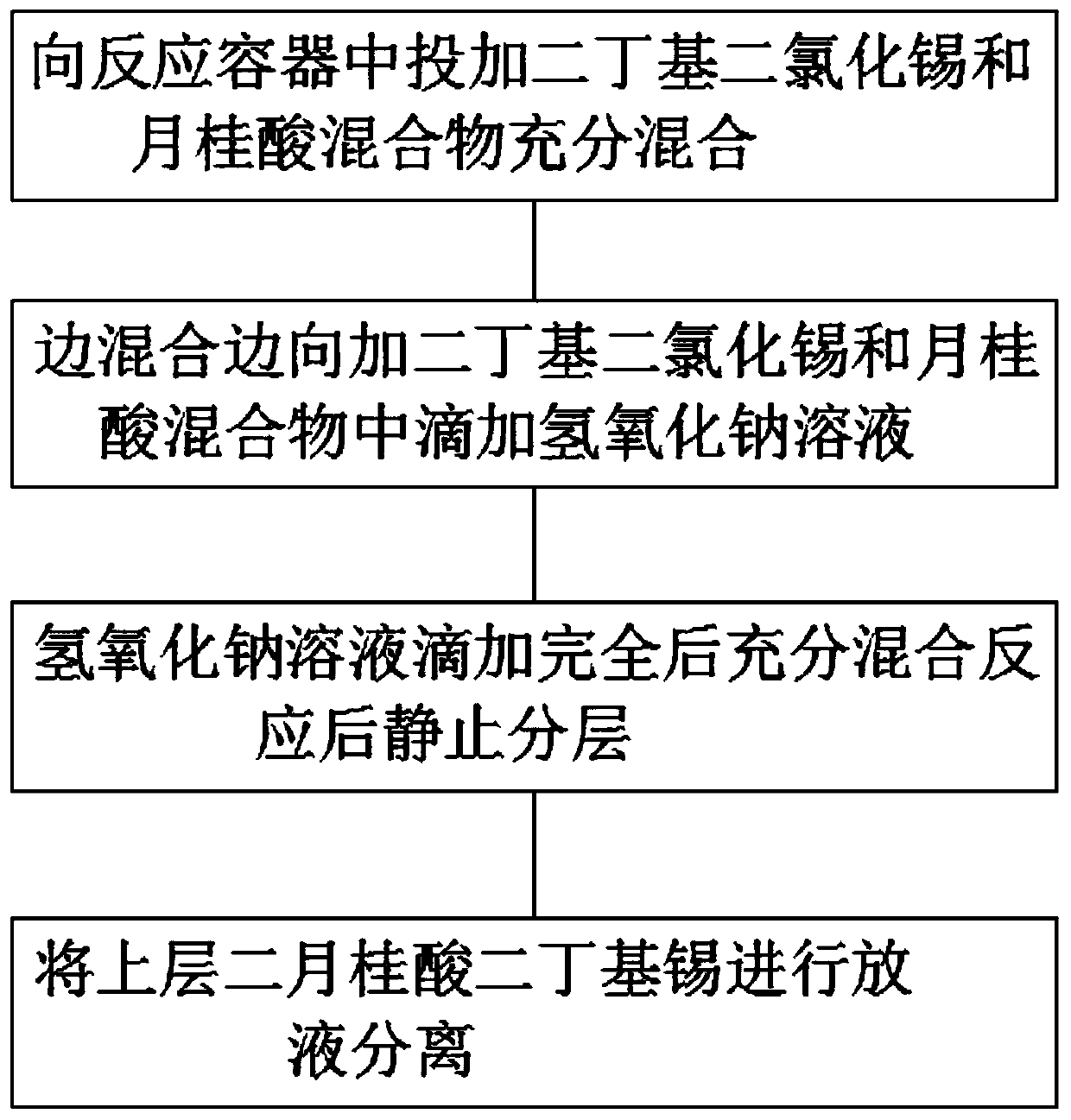

[0013] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be noted here that the descriptions of these embodiments are used to help understand the present invention, but are not intended to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below may be combined with each other as long as they do not constitute a conflict with each other.

[0014] see figure 1 The process flow diagram, this specific embodiment discloses a kind of dibutyltin dilaurate preparation method, comprises the steps: (1) in reaction vessel, add dibutyltin dichloride and lauric acid mixture and fully mix; Feasible , in this specific example, can take by weighing 304g dibutyl tin dichloride and 650g the lauric acid mixture that contains the lauric acid of 60% by weight and place in the multi-port reaction bottle of 2L capacity, adopt ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com